| Author | Message | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 640 Registered: 4-2015 |

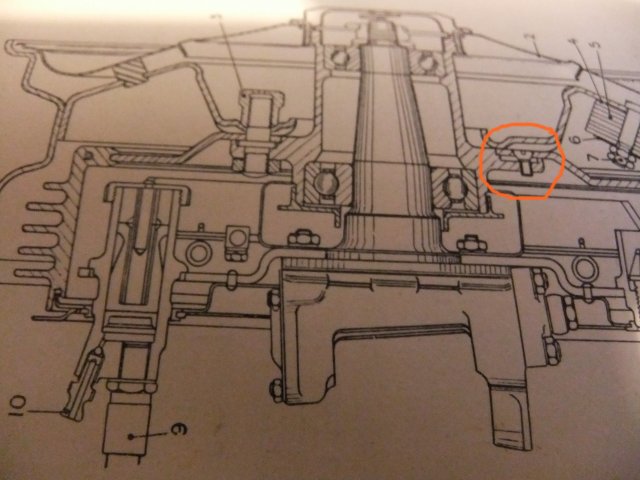

1954 Silver Dawn Saloon, STH53, Freestone & Webb Empress Style Coachwork Time to get out of storage and roadworthy... The goal is to inspect the brakes but a prior owner's efforts to remove the front drums has left two of the three drum retaining screws in hopelessly mangled condition...head slots completely torn out such that an impact driver cannot get a bite. Am I correct from my readings of the service data that I can get the drum and hub assembly off as a unit by removing the grease cap and bearings? This would allow the assembly to be taken to a machine shop to have the retaining screws drilled out, the brake drum separated, and everything put right upon reassembly. It would also allow for repacking of the grease into the bearings as well. Just want to make sure I am going down the proper road in order to get the mangled screws out and then the drum removed before proceeding... . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1675 Registered: 9-2004 |

chris have you first tried using a centre punch to get what's left of the screw out. Another way is to remove with a build up of weld with a welded nut to what is left of the screw. If a no go then yes remove the hub to deal with. Slacken the brake shoes if the drum has a worn lip.  | ||

christopher carnley Unregistered guest Posted From: 109.145.118.0 |

Drill out the counter-sinking, it is 60 degrees. Pull off after releasing the adjustment. Simples. (Message approved by david_gore) | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 645 Registered: 4-2015 |

Thanks for the suggestions. Used a Dremel tool to recut and deepen the bolt slot enough to get a better bite. Put slight taper on edges of flat screwdriver bit to match the remade slot. A few firm wacks with a hand held impact tool and both screws began to budge. A few more wacks and they came out. Drum now off and have found the problem with the brakes. So...on to the next task!! . |