| Author | Message | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 703 Registered: 4-2015 |

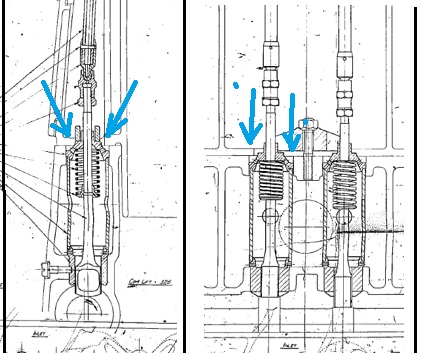

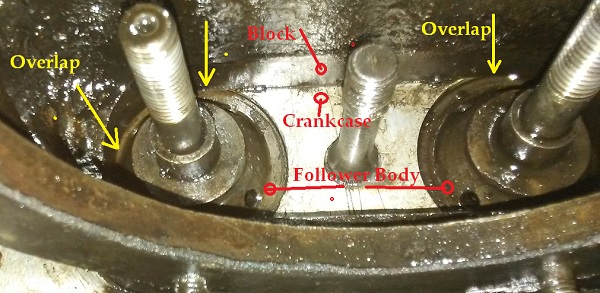

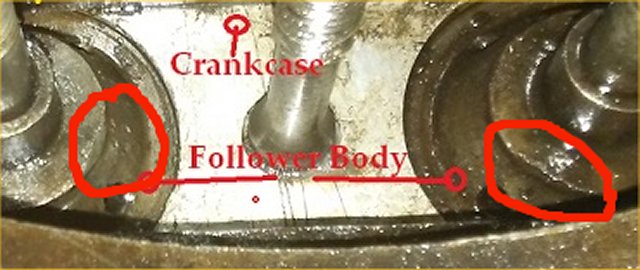

One of the unresolved issues from previous threads was the desire to check the follower to cam lobe surfaces for galling or wear. There are clearly only two ways to do this: 1) Disassemble the engine, or 2) Pull the followers up and out of the access holes on left side of the engine which is clearly the preferable method if it is possible. The question remained, "Was it possible?". Refer to this photo:  Contact results with numerous presumed technically experienced sources were mixed. Of those that responded, one said "I have no idea" and two others stated that it was indeed possible to remove the followers thru those access openings. One declined to give any advice for fear of liability unless I shipped the engine from US to UK for analysis. One went so far as to note "Yes! I assumed you had already had those off. You should remove pushrod(s) and lift up some followers and look at them, clean them and make sure they are not sticking. And that the surfaces are not galled. There is no point in trying to do anything with tappets with those covers in place. You need to get into that engine and look around." Another respondent forwarded the relevant GAD and noted that it did not appear possible that the followers could be extracted through those openings as the blocks covered portions of the openings into which the followers fit in the crankcase below. Observation of the GAD supports that analysis:  So here I have completely divergent opinions/advice. One expert clearly advised removal/observation of the followers as standard procedure in any recommissioning effort, but based on the drawings the task is instead more likely part of a complete teardown to gain access. At the very least, the task would require removal of the head, sump, pistons, and blocks and then the followers could be removed up and out of the crankcase. Certainly not the same type of recommissioning checks like changing oils, checking spark plug gaps, ignition point gaps, pre-lubricating the engine and turning by hand, changing coolant, et cetera. Anyway, the diametrically opposite technical advice basically left me with no alternative to take things apart and find out for myself. Either the followers would come out, or they would not. Period. Over the weekend I proceeded to find out. Bottom line? Sorry. Not happening. See photo:  You can see from the photo that the oval opening of the block above surrounds the area containing two followers in the crankcase below and overlaps the outside diameter of the followers at three of their fours sides. Removal of the followers was definitely prevented by the block. Bottom line is that the GAD is correct and the proposal that the followers can be removed without an almost complete engine disassembly is flatly incorrect. What a pity, but as they say "Them's the facts!!" . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1754 Registered: 9-2004 |

Engine quiet when put into storage! Are you jumping the gun with all this unless damage to the has resulted from incorrect recommissioning of engine, running dry cam lobes. Still not confirmed the cause, gear oil down each tappet push rod would have confirmed piston slap or cam followers etc. BTW to do a strip down as stated in the other thread : To proceed remove all the under trays around the engine remove cylinder head remove the sump con rods pistons. Remove the two engine blocks as they have to be removed to get the cam followers out. For cam removal, this means the radiator has to come off to get at the timing wheels, slipper drive to be checked and adjusted. Best of luck............. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 704 Registered: 4-2015 |

Stop "choking the chicken" and tell me something I don't already know or have already previously stated. Refer to above photo of the overlap and you will notice holes in the tops of the follower mechanism. Guess what? Oil that was liberally poured down the pushrods prior to starting the engine flows thru those holes and down thru the follower mechanisms to lubricate the cam lobe and follower surfaces and was likely distributed by turning the engine with spark plugs removed at the very beginning (as well as oil into the cylinders to lubricate the rings). It should be clear that every attempt was made to pre-lubricate the engine but if despite those precautions there is damage to those surfaces, that cannot be rectified by anything other than an engine tear down which you have grossly and simplistically summarized with the inimitable likes of "Simply remove..." Yes, obviously!! Oh, and by the way, oil down pushrods has no effect on the tappet noise and even if it had, the solution is still the same...engine teardown. Why not concentrate on something specific, like an analytical discussion of "What can cause the running clearances to be .006 wider than the static clearances, and why?" Thanks! . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1755 Registered: 9-2004 |

FYI, The heavy thick gear oil would of settled on the on the cam lobe and followers and with more running down push rods when on idle. If change in clatter then that is the prob. Thin ATF waste of time for testing for noise. Noise still there then piston slap would be a possibility due to the time laid up. BTW, whats going on in the pix looks like someone has taken to the hammer!  | ||

christopher carnley Unregistered guest Posted From: 109.145.118.0 |

OOH! "Chokin, the chicken" that,s awful slang. (Message approved by david_gore) | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 706 Registered: 4-2015 |

Christopher... Back when I was an 18 wheeler owner/driver (lorry in UK) the other similar was "spanking the monkey"! | ||

christopher carnley Unregistered guest Posted From: 86.186.129.35 |

I have heard it all before! Imagine my surprise to learn that you are an ex "Teamster".. "Duel". (Message approved by david_gore) |