| Author | Message | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 658 Registered: 4-2015 |

1934 Phantom II 126PY Upon recommission from 15 years in storage, the engine ran smoothly but exhibited an unsettling clatter which seemed to be coming from about mid-engine in terms of height. Above a certain modest rpm it seemed to be more of a "slapping" than tappet clatter. I added a bottle of Marvel Mystery Oil to engine oil but no change in condition. Above about 40 mph the clatter was simply horrendous. Visions of engine tear down were haunting, but I also speculated that the lifters (or something else) were gummed up and causing the slapping commotion. I then added a bottle of "Motor Purr" which is a volatile fluid that in the past on other engines has successfully quieted stuck lifter chatter. I poured it over the pushrods and valve springs and within a few miles of driving the clatter began to mitigate noticeably, but still while it was "less", the distressing sounds emanating were considerably more than the expected and anticipated gentle tickover and simply the sound of the whirr of the fan as the only noises audible. I changed the oil and over the next day repeated the Motor Purr sequence three more times. Each time the clatter became marginally less obtrusive, but it is still oppressive compared to the way it "should" be. I noticed that as the "slapping" coming from mid engine was reduced, the remaining noise more clearly resembled loose tappet clearance chatter so attempted to check clearances there. Unfortunately while data calls out clearance of .003" and Raymond Gentile in The RR Phantom II Continental suggests .004" at the expense of a bit more noise, my feeler gauges only go down to .006". None the less, that still allowed me to verify that the gaps were not WAY too wide as suggested by the clatter and what I was rather hoping in order to find a cause for the clatter. I can say that the .006 feeler would only barely start into the gap so I speculate that if not set properly they are likely still no wider than .004" or .005". Sorry for the long story, but I am rather out of ideas. Any thoughts as to what could be causing the clatter and any ideas to try to get a resolution short of tearing the engine apart...looking for the unknown. . | ||

Jonas TRACHSEL Prolific User Username: jonas_trachsel Post Number: 153 Registered: 2-2005 |

Christian I fear the worst for your tappet clatter. Camshaft and tappet wear is a known malady of these engines. Measuring the tappet clearance with a feeler gauge will not show you the actual clearance as the tappets are worn hollow where they ride on the cam. Ultimately this means tearing the engine apart. Sorry for the bad news | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 659 Registered: 4-2015 |

You can hear the weeping, no doubt! I'll have to start reading the various manuals about engine. Head off. Camshaft out at the very least, the later of which is easiest with engine removed since camshaft probably comes out of front of engine? or is it an in place operation? . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 662 Registered: 4-2015 |

P.S. I suppose that as long as I keep engine rpms down and just use the PII around town and stay off any over 50mph areas, this job can be delayed for awhile as I get organized and prepared which includes compiling as much information, manuals, videos as possible, as well as any special tools. Any suggestions as to reference materials to collect and study will be most appreciated. Somewhere I have the Haynes book on overhauling prewar engines, but I seem to recall it was just small horsepower. Steph Boddice has a series of photos on his website, but again that was small horsepower. Any direction here will be followed and appreciated. . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 663 Registered: 4-2015 |

Jonas... Slide with me in terms of guarded optimism here. I just quickly went back to Boddice's website and see that pulling the camshaft is probably a major operation most easily accomplished with engine out. However, here is the faint glimmer of hope: My recollection (almost positive) is that 15 years ago when I stored the car (I acquired it at an awkward time in my life, took it out one picnic and then stored it until recently.) it ran just perfectly. I have owned enough Rolls-Royce in the past 40 years that I would have immediately recognized the current chattering as improper and remembered it so whatever happened did so as a result of idle storage rather than use. What do you think the likelihood is that the tappet mechanisms (Boddice has a good photo of one) are still gummed up and that removing the head, blocks, and then the tappet mechanisms may restore proper operation and the front of engine and camshaft may never have to be removed? Faint glimmer of possibility?? Thanks! . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1685 Registered: 9-2004 |

Christian. Was the coolant drained at that time of storage. Don't panic yet, tappets get worse when engine is hot. IMO you have some piston rings sticking. DO a few start ups idling to hot and leave to cool. | ||

christopher carnley Unregistered guest Posted From: 109.145.118.73 |

Christian, If the noise lessens when the engine is thoroughly warmed up, you have "piston slap". (Message approved by david_gore) | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 664 Registered: 4-2015 |

Patrick... No...coolant not drained. Simply parked the car and closed the garage door. There was a lot of personal stress at the time. Fortunately there seems to have been no ill effects cooling wise. So far coolant temps are running perfect at 70-75C even with prolonged idling and climbing hills. Calorstat controlled radiator shutters are also functioning properly. Oil pressure is also proper at 25 when engine warm. Idles at 10. Immediately jumps up to 25 as rpm increases. I have not bothered to do compression test though. Absolutely no visible exhaust smoke, oily, black, or otherwise whether idling, accelerating, or decelerating. Idles perfectly smoothly on Magneto only and at an amazingly low rpm as expected. On coil ignition only there is a bit of roughness to idle and "searching". I have put new plugs in coil side, adjusted the steering quadrant mixture, but nothing else as there are greater issues than barely rough idle to concern me at the moment. Over the last week I have driven the PII daily on numerous around town errands and a few 10 mile higher speed trips so there have been numerous cold to hot to cold cycles. I suppose that I will continue with the pouring of fluids down the pushrods in the hopes that it is the lifter mechanisms that are gummed up given that the problem did not exist prior to storage and that the repeated treatments have each yielded incremental although seemingly diminishing improvements so far. Today I will try ATF down the pushrods and also drain off a bit of the sump oil to avoid overfilling and see what happens. Seems like what have I got to lose? . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 665 Registered: 4-2015 |

Christopher... Just saw your message. What is "piston slap"? No, the noise(s) seem to be rpm related rather than engine temperature related and have been affected by the Motor Purr treatments. The possibility of gummed up rings does however remain. Would a compression test reveal anything? I suppose I should do one anyway just for the record. . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1686 Registered: 9-2004 |

Christian, could you retard the timing a few degrees and see what the change does on start up and with a short run. Possible that top compression rings or ring may be part sticking and or some minor rust on part of the bore due to a very slight coolant leakage or condesation etc over the years. I would also change oil to a semi synthetic and run for a short period before returning to your normal oil. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 487 Registered: 10-2008 |

Chritian, there is a posting by , I think, Norman Geeson, regarding adding ATF to the engine oil to free off noisy tappets on MKIV, S1's etc. I don't know whether this is relevant. Mark | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 666 Registered: 4-2015 |

Mark... Yes. I am doing that treatment today. Have mixed ATF and Seafoam equal parts and pouring maybe 1/2 oz down each tappet, driving a few miles, and repeat. After first application so far no change, but will continue. . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 667 Registered: 4-2015 |

Patrick... At idle I can vary (advance/retard or early/late) ignition spark thru maybe 30 degrees from the steering quadrant but any setting is overridden by a advance mechanism when rpm increases. Position affects nothing in terms of the subject noise. If you are referring to valve timing, I doubt that has any issue either given that the engine ran perfectly/noiselessly prior to storage. My bet is that the issue is storage related/induced. If however in the end it requires an engine teardown...that will be most interesting indeed and I look forward with a bit of trepidation but resolve that I can do it. Meanwhile the Phantom is quite fun and satisfying driving around town on daily errands and under 45mph. . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 668 Registered: 4-2015 |

Christopher... I googled piston slap and while I doubt it is an issue, if a teardown is necessary the pistons appear need to be removed prior to block removal which is necessary to get to the lower tappet mechanisms anyway so they can be inspected and remedied if necessary at that time. Thanks for the heads up though. . | ||

Jonas TRACHSEL Prolific User Username: jonas_trachsel Post Number: 155 Registered: 2-2005 |

Christian The tappet construction of the P II engine is not comparable with the Small HP engines nore with the P III. P II tappets are squareish in section. This prevents the tappets to rotate in their guides. Furthermore this construction prevents proper oiling of the rubbing surfaces of the cam and tappet. Several specialist workshops have engineered/developed improved tappets (this info in case you will have to tear down the engine). Another thought: You think that your tappets are gummed up. How would this manifest itself? Clattering means that the tappets would stick in a position of increased tappet clearance. In other words: The valve springs would not fully push the tappets down onto the camshaft. That in turn would leave the valves partly open. Make a test: Close the valve clearance to zero and see if the clatter disappears. Of course this situation is not meant for prolonged driving, just for a test. I see no problem in continuing to drive your P II in the near future until you are prepared to bite the bullet. Camshafts and tappets will have to be replaced in an engine rebuild anyway. Only drawback: The clatter will further increase until it is unbearable for you.... | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1688 Registered: 9-2004 |

"Each time the clatter became marginally less obtrusive, but it is still oppressive compared to the way it "should" be. I noticed that as the "slapping" coming from mid engine was reduced," "Idles perfectly smoothly on Magneto only" The noise being less points to some freeing up. Tappet noise will only show its self with excess clearance, sticking valve open, worn camshaft lobes etc If ok when stored then engine would run rough on the cylinder or cylinders with a stuck open valve. Have know the gudgeon pin or called I think wrist pin to dry out and become a bit tight causing the piston to tap. Time to move on and use semi synthetic oil and get the load bearing properties etc to work wonders. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 669 Registered: 4-2015 |

Jonas... Thanks for the idea to probe the circumstances by reducing the rocker arm tappet clearance to zero and see what effect that produces. Patrick... What have I got to lose by changing oil again, so I will especially since the "Seafoam" product is touted as a sludge and varnish remover and after it has been applied and allowed to work, the oil should be changed anyway to remove any sludge and/or deposits the treatment has removed. Please clarify the difference between "semi-synthetic" and what I presume is also a "full" synthetic. A blend I presume? If "some" synthetic in a blend is "good" then why is not "full" synthetic better? Meanwhile and for the next day or two, time allowing I am working on a Springfield Phantom I which is the last of four cars "parked and forgotten" at that point 15 years ago to see what surprises/grief it will present. So far I am 2 for 3 being just fine and showing no ill effects from the storage. Both the 25/30 and Derby Bentley fired right up and purr like they should. Too bad about the PII. Fingers crossed on the Phantom I. . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1690 Registered: 9-2004 |

Fully synthetic is just the cost factor to consider. Hope all goes well with the P1. | ||

Norman Geeson Unregistered guest Posted From: 81.110.34.153 |

Christian I must declare to have no direct knowledge of the PII engine, although in a small way I have studied the worn camshaft problems including those on the PIII….…. more later. Having said that, a number of things are common to engines that come out of long periods of storage. Initially you might find the following of some help, there are other possibilities but pressing time precludes others until after Christmas. Assuming no maintenance has been carried out, the engine was in good order and exhibiting no undo noise before its 15 years storage we have the following scenario. At least two valves will have been open, it is possible one valve was even fully open and others just off their seats. First take the example of a fully open valve for illustration. The valve stem will have been protruding into the port, exhaust or inlet and in that position the exposed stem will start to corrode. Once the engine is rotated the valve will come under the influence of the valve springs and try and retract, bring corrosion and gum into the valve guide. The valve shuts slowly at best and possibly not fully but in any event the valve movement does not follow the cam or the rest of the valve mechanism. The resulting valve lag results in noise. This scenario can also occur with valves that have stood shut and are now driving debris into the guides from the top end. There are a couple of ways to check if the valves and mechanism are free. Remove the valve cover and starting at the front, with each piston part way down the bore to clear the valves, depress and open each valve in turn. Ensure they open and return freely and completely. The other way I prefer, in addition to the above method is as follows. Obtain a full but cheap set of feeler gauges. Check and/or set the tappets as follows, starting at the front valve, turn the engine until the valve is fully open, from that position rotate the engine 180 degrees and then check the tappet clearance, Repeat the exercise with all the valves and they will be set correctly. Pick a feeler gauge about 0.002 inch thicker than the one used for checking the tappets. Start the engine and at idle speed insert the thicker gauge under the rocker as you would for tappet checking. If the gauge goes in easy try a thicker gauge, if it still goes in easy it is a sign that the valve is binding. If the gauge is hard to insert try the original tappet gauge, should this fit you have a valve that is performing well at idle. With some dexterity and a helper, it is possible and desirable to try this exercise at higher RPM and in general prove that the valve opening/ closing mechanisms are operating correctly. You may find the engine stumbles a little when you insert the gauge at idle and you may also find it stops some of your noise. If the latter occurs suspect a lazy valve closure. Take precautions to keep clear of the fan and other rotating parts and do not wear loose clothes. You will soon find out if the top end oil feed is working <smile>but it is permissible to wipe out the oil troughs for a short test period. Oh, you purchase a cheap feeler set because they will be indented a little after running under the rocker heads. Maybe worth noting, checking tappets in the running condition works well if the valve rockers are not indented by wear, and is a method I used on the inlets on my R Type. (Message approved by david_gore) | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1691 Registered: 9-2004 |

Forgot the additive for the fuel tank. Redex will also help the process of freeing part stuck compression rings and clean and lube valve guides. | ||

David Gore Moderator Username: david_gore Post Number: 2785 Registered: 4-2003 |

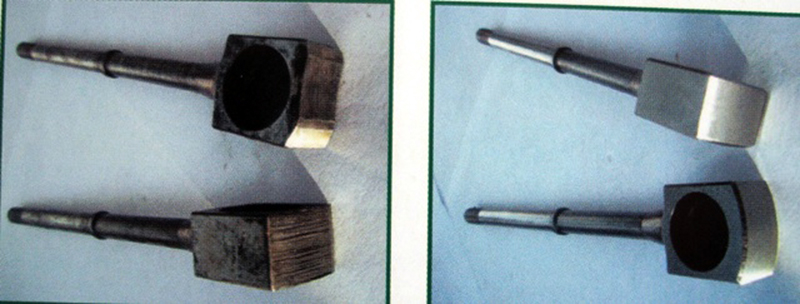

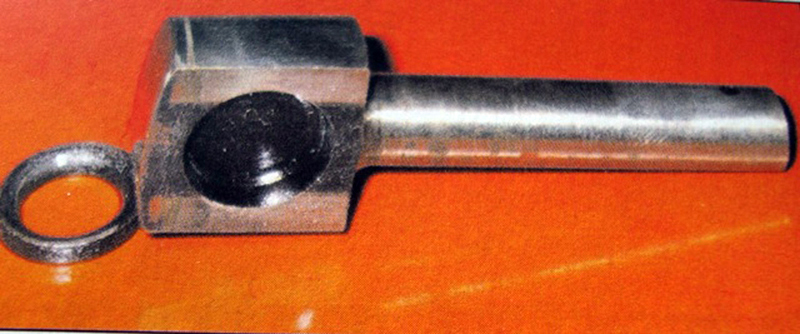

Christopher Carnley has forwarded the following advice and photos for posting on his behalf: "Would you include these pictures of the Phantom 2 tappets, (cam followers) in the post of Christian, together with these notes,please? The l/h one shows badly scuffed faces, with the new on the right. The tappets are like "nails" made of case hardening steel with a very thin case, and entirely different from the small horsepower roller type. The valve gear clatter is a fact of life with the P2 as many specialists will comfirm, and it caused one guy in the USA called Herb Wuesthoff (RROC) so much concern that he redesigned the cam shaft, and improved the materials and hardening, to great success. The results were published in "The Flying Lady". The rocker clearances are .003" and inserting a .002" feeler gauge spacer is asking for trouble. The second picture with the orange back ground is the Phantom 3 tappet, to replace the original hydraulic ones. The production type shown, suffered the same dry welding scuffing problems, and replacements were hard chromed with Delchrome. The example shown has a Stellite face brazed on as you can see. These nail-like tappets were used in the Edward Turner designed Daimler V8 engines, and the top rocker/tappet covers are filled with glass fibre insulation to absorb the clattering racket.   . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1694 Registered: 9-2004 |

My observation on this, If the car was ok [Quiet] when stored years ago then a worn tappet cam follower is not going to wear to the extent of giving noise in the short time since recommission. Besides the noise has since gotten quieter with use. Cause imo piston top compression rings partly stuck. N. Geeson has said a lazey valve closing. However the engine in that case would run rough on tick over. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 671 Registered: 4-2015 |

Gentlemen... Thanks to all. Hope you are having a Merry Christmas and enjoyable Epiphany Season. I was raised in the Anglican Church and Christmas is but the beginning of the season, rather than the end. Anyway back to the issue: Norman...Thanks for the very illuminating discussion which I believe is likely spot on as it describes events that can be correlated to extended storage. I just did the test with expendable feeler gauges (yes, it does make a mess of them!) and found that while the clearances are correct when cold and stationary, at a medium idle they were all at least .008 and a few as wide as .010 and even .012. No wonder there is such a clatter present! Whether some lazy springs are contributing remains to be seen, but in any event I believe we are zeroing in on the cause of the clatter. The resolution I suspect will be a bit more complicated and will likely involve valve removal and inspection as well as new seals. Looks like head removal is going to be on the agenda and if so, will have to wait until I get more completely relocated to Montana where my shop has a smooth concrete floor and good lighting. Meanwhile can it hurt to keep up the application of a light oil (ATF?) being squirted into the springs in an effort of get it onto the seals and when driven, keeping speeds and rpm down to a minimum? Around town and in 3rd or 4th gear, the engine is barely above idle rpms, or is that ill-advised given that any mileage with the clearances that wide may contribute to the scuffing that presumably/hopefully has not yet developed? P.S. I noticed that as I inserted the feeler gauge and thus reducing the clearance on that valve momentarily to ".000" it seemed to also affect the idle rhythm a bit, or maybe it was just my imagination Also...I have not yet tried Jonas' idea of reducing the clearance from .003 to.000 when stationary, but given the circumstances as they are evolving, would this really make any/much difference given how wide the clearances are when at medium idle, i.e. would only reduce those at .010 down to .007 which is still too wide. Is it worth a try just the same? . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1698 Registered: 9-2004 |

Off topic but a little note on the Daimler 2.5 V8 fitted to the SP 250. The tappet foot [cam followers] are indeed like the Turner designed engine.  However worth noting is that the inlet clearance is 11 thou and exhaust 14 thou. With the correct old type oil changed often and the later oils that go the distance I never had a problem with noise, also can never remember seeing fibreglass within the rocker covers! Maybe fibre glass on the outside of a Majestic Major engine. That's one car that I have not owned but have owned and ran a six cylinder Daimler Majestic. Lovely riding car in more ways than one in my misspent youth. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 673 Registered: 4-2015 |

I did a few more experiments which seem to confirm Norman's lazy valve closing proposal. Following Norman's suggestion of checking valve stem clearances with engine running confirmed that they are running much too wide and thus the origin of the clatter. Upon following Jonas' suggestion reducing valve stem clearances to .000" I found that doing so seemed to noticeably reduce the clatter as would be expected. While doing so I discovered another corollary symptom that may or may not either cause or may simply contribute to the lazy valve closing. On some of the valves as I closed the clearance, I could feel distinct resistance at .000" given that beyond that point the adjustment screw is attempting to lift the valve against the resistance of the spring. On other valves there was no similar tactile sensation, the spring gave marginal resistance, and it was possible to simply continue turning the adjustment and observe the valve being pushed off its seat. Clearly some of the springs were substantially weaker than the others and would this likely affect the rate of valve closing and thus create the "slow or lazy" issue? Additionally, I noticed that when there is no spring tension on the valve, it is possible to easily turn the push rod with the fingers. At the moment the adjustment is reduced to .000", the pushrod can no longer be turned as it is then under the spring pressure. I found that it was therefore clear when the clearance reached .000" simply by the feel of the pushrod turning. Indeed, when it came time to restore the cold settings back to .003", I found that I could very reliably (within one or two thousands) tell where the proper setting was: at about 1/6 turn of the adjustment screw beyond the point where the pushrod began to turn (at .000"). Anyway, the engine is back to properly set up with .003" clearances cold and I will continue the flushing of the valve stems and stem seals with light oil for lack of any better ideas at the moment. I appreciate that the proposal that the springs can get weak from storage is dismissed in some schools as unlikely, but irrespective...the evidence is there apparently. Once I can source the tool for removing springs in place, the next obvious experiment will be to install new springs and see what happens. Am I overlooking anything based on these experiments or reading too much into the apparent results? . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 682 Registered: 4-2015 |

Update and Question: What is the more relevant tappet clearance measurement...static (engine not running) or dynamic (engine at idle)?? I assume that theoretically they should both be the same, that is, you set the tappet clearances with engine off and cold. When the engine is running at an idle, the clearances SHOULD be exactly the same as when cold DISCOUNTING of course that once the engine gets up to operating temperature the clearance, if anything, SHOULD narrow. Is there any reason why the clearance should or could be MORE at idle than not running? THAT seems to be my specific problem. That said, it is the clearance when the engine is running that is relevant in terms of operating efficiency and so if it is necessary to reduce the RUNNING clearance in order to be within the specified tolerance, does this cause a problem? Some background: Review the above thread and you can see that I had significant tappet clatter. Clearances were set per manual at .003 cold, but when clearance was measured at mid-idle, they were found to be wider...half at about .006 and the others at .008, .010 and .012. It was suggested to reduce the static clearances to .000 and see if that affected the clatter. In the process of doing so, it appeared that some of the valve springs were weak which would possibly explain the lazy closing due to weak springs as the reason for the wider idling clearances. Having procured the valve spring removal tools and a crank tool from private party at "worth their weight in gold" prices, and springs and seals from Fiennes Restoration, I proceeded to install the new parts. Results were mixed. Good news and bad news. Good news was that I had no parts left over after the task was completed!! Bad news was that the replacement springs made little if any difference in the clatter. Good news (I suppose) is that the exercise resolved the idea that weak springs were causing lazy valve closings and thus the excess clearances and resultant clatter. Upon repeating the check of clearances at mid-idle speed I found that the clearances were wider that the static...same as before...half at about .006, the rest at .008 and 010. I then reduced the clearances of the six that were excessively wide down to .000 when engine off, cold and then rechecked the idle clearances. As expected, they were reduced by the .003 and all but one measured tight with a .006 expendable feeler. One was still loose fit, i.e. still wider than .006 where running (the one that was .010 before). A driving test indicated that THIS adjustment had a material effect on the tappet clatter, since it was now uniformly less that before, but still noisy since the running clearances were about .005 or .006 rather than the ideal .003, but a lot better than .008 and .010!! So...we come to the meat of the question: Since the real issue is the clearances when the engine is running, is this "adjustment" likely to cause problems? It is basically a "workaround" for the running clearances being wider than the static clearances. In a perfect scenario, the running clearances should be the same as static, but the only thing the engine cares about is running so in the current case, I am going on the premise that adjusting the clearances based on "running" will do no harm. Even though the static clearance is .000 and one might say that this will burn the valves, on the other hand, since the running clearance is .006, that will not burn the valves. Yes? No? What do you all say?? Forgive the wordy dissertation! . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1730 Registered: 9-2004 |

Imo the clearance of the tappets when hot will be more not less. The noise could be some of the valves partly dragging in the guides but that would get better when hot. Of course it could still be a pistons compression ring or rings freeing off as time goes by. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 683 Registered: 4-2015 |

Patrick... I was thinking that as temperature increased, the pushrod length would also increase and the clearance would decrease, hence the reason a tappet clearance set too tight can lead to burned valve. Why does clearance increase in your theory as temp increases? In any event, the real issue was whether at any temperature, whether cold or hot, the static and running clearances should be the same as each other. Again, my thinking was that yes, they should be the same as each other when cold, and the same as each other when hot, even though when hot that same clearance (static and running) may be a few thousands different due to metal expansion. . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1736 Registered: 9-2004 |

Christian In many cases the the valve clearance will not increase when hot on many engines. However it is my educated guess that with the Phantom engine configuration ie cast iron long stroke block, alloy head with the thermal expansion difference, this will not let the engine heat up at the same rate, the cylinder head temp will rise quickly [more clearance] but the push rods block etc will have a lower expansion in comparison. Closing of valve clearance gaps over time [mileage] hence service schedule adjustment is in most cases down to valve seat wear. Adjustment when cold is a must. Fast forward to the all alloy engines and the use of hydraulic tappets to resolve the problem of expansion and the new valve problem of valve head recession in need of a better word makes the engines so quiet. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 684 Registered: 4-2015 |

Thanks...but what about the static versus running question? I repeat it: If you set the clearances cold with engine static (not running of course) and then start the engine, should the clearances just set remain exactly the same or change? i.e. should the static and running clearances be the same, or is there a reason why they might not be? . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1737 Registered: 9-2004 |

Christian, IMO the configuration of your engine the tappets will widen from static cold. IMO to get to the bottom of this or cut to the chase set all tappet clearance as per spec, with the rocker cover still off trickle some 140 heavy gear oil down each push rod and start the engine [Idle]. If the noise has stopped for a short while then it confirms the valve gear, cam followers and cam are the failing. If no difference then a piston problem maybe. Does your engine have the high lift cam some were removed to the old type ETC. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 685 Registered: 4-2015 |

Patrick... Thanks, but the real question is still not being addressed: AGAIN: All other things aside, should the measured static clearance be the same as the measured running clearance? To me, the answer is "yes, obviously" and if they are NOT the same, then there is clearly something else contributing and causing that discrepancy. Is there any consensus here? BUT...the discussion at this point is NOT about the other issues that could contribute or cause the tappet clatter, but SIMPLY the "static clearance same as or different from running clearance" question. Let's keep the discussion from going elsewhere until that initial question has been answered. . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1738 Registered: 9-2004 |

AGAIN: "All other things aside, should the measured static clearance be the same as the measured running clearance?" NO NO NO. Please do the gear oil test as it will confirm the fault one way or another !!!!!!!!!!!!!!! | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 686 Registered: 4-2015 |

You say "NO,NO,NO" You mean to say that in a properly running engine with no problems and as designed by the engineers, that if you check static clearance and then turn on the engine and immediately check running clearance, it will NOT be the same? . | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 496 Registered: 10-2008 |

Christian,in an ideal situation, with no wear, no temperature change between static and running whatsoever; then static and dynamic gaps would be even. Reality is not ideal and I think Patrick may well be correct. Have you carried out a cylinder leak down test ?Has a valve guide "picked up " on startup after storage ? With an unexplained noise and a valuable engine, I would probably remove Head and pistons for a precautionary check. Mark | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 687 Registered: 4-2015 |

Mark... Thank you for your contribution. While a teardown to some extent yet to be determined may be in the offing (cleaning and removal of accumulated sludge at the very least) for the moment I am trying to fixate on any of the more apparent symptoms before embarking on either a fishing expedition or exploratory surgery. The recent posts have tried to keep things simple and ask one question at a time and get an answer to that question before asking the next. Otherwise things get out of hand and complicated quite easily. So, the answer is as expected, that "all other things being equal" and "nothing changing mid-stream" the static and running measurements should be identical on an otherwise properly functioning engine. Obviously then the takeaway is that if the static and running measurements are not the same then clearly there is something in play which leads to the question of what that may be. In my case the two measurements are NOT the same. Further it is observed that the measurements DO NOT change irrespective of whether the engine is cold or hot. The possibility of irregular/weak valve springs or valve seal issues have been ruled out as they have been replaced. Valve stem seals have been replaced so any issues there have also been ruled out. Rocker arms appeared to be fine. No galling, indentations, flat spots, et cetera. Valve guides were in place if that is what you refer to as "picked up". Oil passages were open and feeding oil to the assembly. What is the "leak down test"? Is it a "compression" test? The issue is that the running clearances are wider than the static. Reason yet to be determined. Since the engine is only aware of the clearances when it is running, the question is whether it is appropriate (in this unique case and until the cause of the divergence is determined) to set the clearances based on the running measurements, since those are the only ones that affect the engine. Finally, last night I discovered another issue that may or may not be a causal factor but which at the very least needs to be addressed and eliminated. I removed the front two (of the six) side plates that allow observation of the lower push rod and upper cam follower area. See photo:  You will see that there are two nuts, one above the other and about 1" apart vertically. This is a secondary valve clearance adjustment mechanism that is set up upon engine assembly and then further maintenance adjustments are done at the rocker area. I noticed that when the cam is on its heel that the corresponding adjustment nuts were LOOSE and this will allow the adjustment to walk around when the engine is running. Whether this is the source of the "static clearance does not equal running clearance" problem remains to be seen but clearly I need to re-do this adjustment and lock these nuts down so that this adjustment cannot change on its own whim as is now the condition. Unfortunately this is not covered anywhere in the manuals, service bulletins or anywhere else that I can find. The adjustment is "alluded to" in the Phantom I manual but simply with the suggestion to consult the RR Depot for information. Of course that was fine in 1935, but I suspect would elicit a blank stare in 2018. Does anyone have any information on this adjustment? Christopher Carnley, can you help or refer me to someone? Clearly if I get into tearing the engine down beyond simply head removal (which is the furthest I have gone in my 40 years of RR/B ownership) I will need some (a lot) of technical advice and would like to get that relationship established before embarking. Can anyone help?? Thanks. . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1739 Registered: 9-2004 |

As stated the car was garaged with a engine that was a running quiet at that time. IMO Fast forward the 15 years and if the engine was started with all the snake oil additives and no oil poured down the push rods then the state of play is now damage to the hardening worn off the cam followers. IMO the the tappet adjustment should be carried out COLD 3 thou no more no less. Forget doing any valve-lash adjustment on the lower secondary adjustment as you say it is factory set. As I stated pour some thick gear oil down each push rod[ slow moving] and start engine to see if it runs quite on idle. If it does then a engine strip down is a must with a new cam shaft etc. To proceed remove all the under trays around the engine remove cylinder head remove the sump con rods pistons. Remove the two engine blocks as they have to be removed to get the cam followers out. For cam removal, this means the radiator has to come off to get at the timing wheels, slipper drive to be checked and adjusted. Best of luck............. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 688 Registered: 4-2015 |

Thanks for the "advice". While I did not specifically detail my recommissioning procedures, give me a bit of credit for common sense. In fact I did take great pains to lube the engine and hand crank it before starting per recommissioning service sheets. Oil injected into cylinders as well as oil poured down pushrods and over rocker assemblies and down valve springs, followed by hand cranking engine to be sure all was distributed. Secondly, although the secondary (lower) tappet adjustments may have been set at factory, you discount that 85 years have passed and there have been numerous "hands" on that engine in the interval, and worse, the adjustments are NOW LOOSE. So much for having been set at the factory!! Additionally there is a bridge piece shown in the above photo that when removed, I presume allows the followers to be removed without engine disassembly (rockers off of course). I am specifically soliciting information on this area adjustments if anyone knows. I have found some service bulletins from 1929 regarding the Phantom I engine that are to some extent illuminating given the similarities between the two engines and which confirm that what I am seeking to do is proper, but absent detailed information as to how it is done. Interestingly enough, these bulletins discount the static clearance setting procedures and advise concentrating on the RUNNING clearances!! Just like I have said seemed to be more logical. Can anyone else help? Thank you. . | ||

christopher carnley Unregistered guest Posted From: 109.148.48.131 |

Are your rocker faces smooth across or are they indented by the tip of the valve stem? (Message approved by david_gore) | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 689 Registered: 4-2015 |

Christopher... Good to hear from you. They are not galled or indented or flat spots. They are curved along the plane parallel to the rocker arm but flat across plane that is perpendicular to the axis of the rocker arm. The curved surface does not have any flat areas interrupting the curvature. The tops of the valve stems are flat, not galled, not indented. The radius of the valve stem tops has a very slight bevel to it as expected. I suspect that a contributing factor to the clearance issue is the non-adjusted (i.e. loose) lower adjustment nuts shown it the above photo. I will be working on that later today or tomorrow and also plan to remove one of the bridge pieces to see what happens. I believe that this is the procedure to get the cam followers out in order to inspect them, but have received no confirmation or cautions from anyone to whom I have emailed asking advice. . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 690 Registered: 4-2015 |

P.S. Tonight checked and tightened all of the 12 cam follower to pushrod length adjustments. Turned out that only the first two (inlet and exhaust for cylinder #1) were loose. All others were tight. Running rocker arm to valve stem clearances are still a tight .006" both cold and hot. Compressions are 60#, 60#, 65#, 65#, 70#, 70# which, while not perfectly level, are close enough to not get frantic about. . | ||

christopher carnley Unregistered guest Posted From: 109.146.90.159 |

I have a contact for you who is rebuilding a P2 engine from scratch,as of present called Andreas. www.garageandreas.com (Message approved by david_gore) | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 691 Registered: 4-2015 |

Christopher... Thanks for the tip. I will correspond. The immediate question in whether it is possible to remove the cam follower mechanisms by removing those bridge pieces and lifting the followers up and out, or not. I have received off forum replies at both extremes..."yes"...and "no"! I have even received General Assembly drawings that seem to support the "no" response, but the "yes" was someone with decades of specific experience...so this issue is yet unresolved. In the end I may have to simply remove rocker assemblies, pushrods, the bridge pieces and then see which party is correct! . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 743 Registered: 4-2015 |

Update: The tappet clatter remains unresolved however I did have an opportunity to take the valve springs that had been removed under suspicion for having different tension specifications (perhaps from the prolonged storage) to a cylinder head rebuild shop. I used their valve compression test tool to check. Turns out that they are all equal and none tested weaker than any of the others. The tensions were uniformly requiring 60# to compress 20mm and 100# to compress 30mm. I have been not been able to determine what the proper specifications are, nor did I check the replacement springs sourced from Fiennes prior to installation but at the very least the conjecture that the previous springs had various tensions has been refuted and the issue put to rest. What remains a mystery is why there was a different feel to them when compressed with the rocker arm adjustment screws (details provided earlier in this thread). As previously noted, the replacement springs had no effect on the tappet clatter issue. . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1793 Registered: 9-2004 |

Thanks for the update. If the head was not removed to fit new springs then could still be a sticking valve stem in the guide. If head was removed the a tight valve guide would have shown up, in that case the heavy gear oil trick down the push rods would confirm the fault.......... | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 744 Registered: 4-2015 |

Refer to prior sections of this admittedly lengthy thread. You are going over ground already covered. Valves and seals replaced in position using the special tools. Stem guides free and smooth to finger only rotation and up/down movement, both before and after installation of new springs. Gear oil down push rods made no difference. In due time I will be draining oil and using snake endoscope thru drain plug hole to see if cam surfaces are visible. Later though on that.... P.S. The clatter is so prevalent and evenly distributed across the length of the engine that a single sticking stem or even a few would unlikely exhibit the observed noise. More likely something else. . | ||

christopher carnley Unregistered guest Posted From: 109.149.198.132 |

Possibly it is aural oversensitivity. However you could be describing "poppeting" where you are hearing the valves dropping into the seats. R-R from the word go were aware of this. The valve gear has its own damper in the form of the string seals which were only ever really intended to be "poppeting" dampers, not oil seals. (Message approved by david_gore) | ||

Bill Vatter Frequent User Username: bill_vatter Post Number: 66 Registered: 9-2004 |

Christian, I have read through all of the posts, and I think there is some good wisdom in several. I would like to make some observations from what I have read. The noise occurred immediately on revival from long storage but was silent when put away. This strongly suggests something happened during the storage. Corrosion comes to mind, and Norman suggested corrosion of valve stems could cause sticky valves. You state your feeler gauges were deformed after you checked clearance when the engine was running. This suggests there is an irregular surface where you were inserting the feeler gauge. Normally with good parts, the feeler gauge would be only very slightly deformed or bent if at all when checking the clearance while running. Christopher Carnley suggested a dished place on the actuating surface of the rocker arm, which would certainly cause the feeler gauge to be banged up. This would also account for running clearance being greater than clearance with engine stopped. Think about what happens when the rocker arm has a dished wear place on it. You check the clearance with the engine stopped, and your gauge bridges the gap, indicating less clearance than actually exists. Then when running, when the valve opens, the feeler gauge is pressed very tightly between the rocker arm and the valve stem, which deforms the gauge but also allows you to feel greater clearance with the deformed gauge. This is a very common problem with the early postwar engines, and certainly could happen with a P-II. When you removed the springs with the "J" shaped tool holding the valve closed, you should have been able to very slightly loosen the valve holding tool and spin the valve with your thumb and fore finger while the spring was off. It is wise to do this with piston at the top in case your action knocks the valve holding tool out of position. You certainly do not want the valve to drop down out of the guide. (%$#&%) Did you try that? If the valve was sticking in the guide (corrosion) it would be tight. The valve should turn very freely when not being restricted by either the holding tool or pressed (pulled) against the valve seat. Sticking valves can produce a horrible noise if they are closing part way (do not stick in the fully open position). Unless you did something awful, like run the engine without oil or oil pressure when you first started it, I think you can reasonably discount the possibility of damaged parts like collapsed piston skirts producing piston slap. Did you turn the engine several rotations with the spark plugs out before starting it to make sure it was not sticking or stuck? Did you prime the oil pump and fill the oil galleries? | ||

Bill Vatter Frequent User Username: bill_vatter Post Number: 67 Registered: 9-2004 |

Temperature related valve clearance changes are caused by expansion of the engine parts. The block expands which causes the clearance to increase. The pushrod expands which causes the clearance to decrease. Normally the block temperature follows the temperature of the coolant, and the pushrod temperature follows the temperature of the oil (oil running down the pushrod during operation). Therefore, when the engine is very thoroughly warmed up with the coolant and oil equally hot, there will be very little clearance difference from cold. However, during warmup, the coolant gets hot much faster than the oil, and therefore, during warmup it is common for the clearance to be significantly greater than when cold. Sometimes the valves will be silent when first started and when the engine is fully warm, but during warmup, when the clearance is increased, you will hear the valve train making noise. The valves should be silent when the clearance is set properly because the camshaft is ground with an approach ramp ahead of the valve being opened. For 10 or 20 degrees of rotation immediately before the valve begins to open and after it closes the clearance is taken up gradually by the approach ramp and the very slow and easy final contact is without noise. Generally the clearance can be a little greater than specified without causing noise, but when it is a lot greater the contact occurs when the tappet contacts the lobe very smartly, bang! It is possible that the increases of clearance when running that you observe are a natural result of the phenomena I describe above. This may also cause increased noise during warmup if the valves are closing almost all the way but not quite. If the valves are not closing quite all the way, say less than 0.010 inch open, the cylinder may still fire. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 745 Registered: 4-2015 |

Bill... Thank you for your observations. Yes. Some sort of corrosion on something during storage is the only thing I can think may have happened during storage. I will eventually get a snake style bore scope and insert thru the oil drain plug hole to see if anything on the cams is visible and if not, that may serve to discount the issue of galled cam lobes and tappet faces...maybe...considering that even with a bore scope tool I doubt that the faces of the tappets will be visible. If anything, only the surfaces of the cams will be visible and of those, I presume that only the surfaces of the lobes are relevant. As to startup procedure, yes, I was cautious to remove the valve rocker cover and plugs (all 12) and pour engine oil over the rockers, valves, and pushrods. I did not at that time have a crank but used the starter to turn the engine with no plugs (both sides of head) and thus no compression. Prior to turning engine I squirted several ounces of ATF into each cylinder. I did NOT prime the oil pump as it never occurred to me and it has never been mentioned as a recommissioning task upon startup after long storage. I can only hope that the turning of the engine without compression sent lubrication to the necessary bearings...but maybe not. I can only hope that such did happen. As to the condition of the rocker arm faces, I examined them when rockers were off and did not see any clear or obvious problems. Certainly not any gouging or dishing. As to corrosion on valve stems or sticking in valve guides, yes, I observed that when the "J" tool was slightly rotated, that the valve would drop under its own weight and that I was able to easily turn it with my fingers as if I was lapping the valve seats, so there was no static sticking. Whether such sticking manifests itself only under operating conditions might make a difference, but they seemed to be free and clear. There was no corrosion on the parts of the stems that were covered by the old string style valve stem seals, nor any corrosion on the parts of the stems of those that were fully open during the storage that showed above the stem seals when fully closed. All in all, that evidence at least "seems" to eliminate the sticky valve theory...unless things change under running conditions. The tapping is evident both cold and when engine fully warmed up so temperature of the guides causing any sticking can also be discounted. That's about all I can say for the moment. . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 746 Registered: 4-2015 |

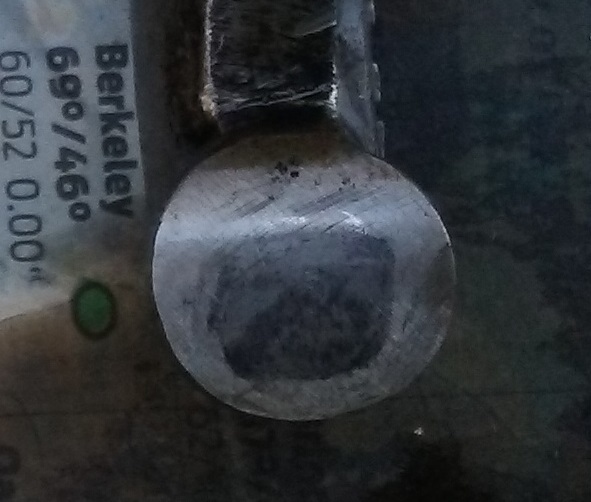

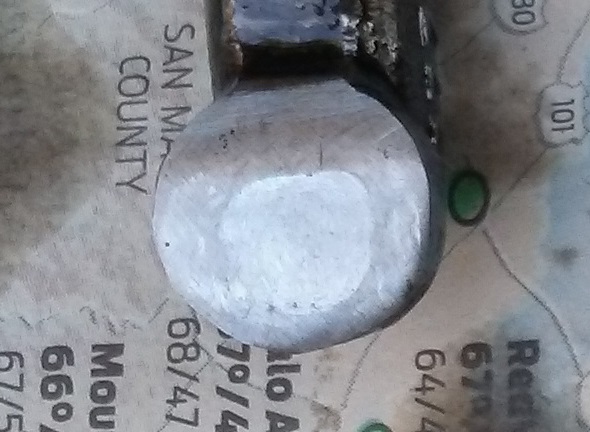

See attached photos of two typical rocker arm faces. The contact area with valve stem is simply a discoloration and not any sort of tactile depression or flat area. Brightening and polishing from contact. The overall issue is that while the noises at least seem to be tappet related, none of the observed data seems to verify this as a cause. and further, that the noises do not seem to be localized to just one area or valve, tappet, pushrod, etc. It is also possible that I am simply misinterpreting the evidence. I suppose that polishing/stoning the rocker arm faces and having the curvatures verified would further confirm or eliminate the possibility of this being an issue. It is just that there do not "seem" to be any clear and obvious damages here and may be another exercise in throwing money at the problem in the expectation of either finding problems or eliminating them as a cause. Further, unlike corrosion, any rocker arm surface issue is not the sort of thing that would result from storage, is it?, and may simply be addressing preexisting conditions that are not the cause of the primary noise issue.   . | ||

christopher carnley Unregistered guest Posted From: 86.140.181.158 |

Well stoned! Poppeting valves in alloy cylinder heads are rather noisy. (Message approved by david_gore) | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 824 Registered: 4-2015 |

Today I switched the EPW Silver Wraith for the Phantom II as the daily driver and want to revisit this thread. First, Christopher...If you have a moment would you please clarify your last comment that was "well stoned". Do you mean that the surface of the rocker arm ends curved surface already appears to be "well stoned" or do you mean to imply that they appear to need to be well stoned in order to address what appear as poorly dressed surfaces? Secondly, I will try to describe one of the engine noises again. This noise seems to be most apparent when passing by a stone wall or fence or other surface that reflects back noise. The noise seems to be coming from the lower part of the engine, under the chassis, from whence it reflects back to my ear in the driver position. The noise can best be described as being similar to a circular glass jar into which you put a few metal coins or other metal objects and then swirl the jar in a circular motion and thus cause the metal objects to swirl around the interior circumference of the jar and in the process create a sort of swirling and scraping sound. Can this be visualized? Not so much a metal on metal scraping noise but rather like coins swirling in a glass container. Any ideas?? . | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1921 Registered: 9-2004 |

New problem by the new noise description , IMO you now have an running valve train with little or no oil. The more you use the engine the more gold coins will fill the jar the more noise, the more cost. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 825 Registered: 4-2015 |

Not a new problem and distinctly different from valve train clatter. Simply a revised description of the various observations. I was previously more fixated on the tappet noise and did not choose to bother the forum with this variant noise. In any case, plenty of oil to rockers and push rods. Visually verified. Multiple times. Still wonder about the condition of the rocker arm surfaces. As noted, the discoloration in the photos is just that...discoloration...rather than irregular surface, dishing, or gouging. In the end, may send the rockers off to Vintage Garage and cough up the $1000 to have the rocker assemblies all gone over and all aspects including surfaces made perfect. Swishing sound is only noticeable when passing a fence or wall that reflects the sound back. Otherwise benign. Seems to be coming from under the chassis...front not rear. A bit of probing the engine with hose to ear reveals no noises from anywhere along the sides, sump area, manifolds, etc. However there seems to be a resonating tinny noise at the front of the first exhaust can attached to exhaust manifold down pipe. The area is covered by some Bijur lines, fittings, and engine side pan but perhaps a pin hole in that exhaust can and or internal baffle(s) loose and rattling/swishing? Need to get it up in the air for access and remove that engine side pan. . | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 827 Registered: 4-2015 |

| ||

christopher carnley Unregistered guest Posted From: 5.80.18.154 |

A good looking motor. The rocker faces look OK to me with little or no depression to interfere with the gap setting. Look up "Aural Hypersensitivity" C (Message approved by david_gore) | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1925 Registered: 9-2004 |

Ok if you suffer from say Autism then the loud noise is not going to get quiet when looking at the car passing shop windows! what temptation with a beautiful car like that. Bit like the early warning radar with walls built along the coast to capture the sound of Nazis enemy planes. Pull the camshaft get it re-profiled and fit new cam tappet followers. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 835 Registered: 4-2015 |

Christopher...Please excuse the delay responding. Thanks for your input. Seems like I should not stress about the rocker end profiles after all. The more I listen to things, the more I am suspecting a minor exhaust leak somewhere. It is on the to-do list to get a smaller diameter tubing to probe around some of the more inaccessible exhaust corners as that is where the sound seems to be originating. Meanwhile other projects take priority. As to the aural hyper sensitivity or mechanical hypochondria...I wish it was, but no. This weekend was the periodic checking, starting, driving of the collection and all the other prewar and postwar sixes were quiet and smooth. Both of the 40/50 large horsepowers, less so. I am told the PIs and PIIs tend to be noisier and perhaps that is simply the fact. If so...pity. Very non Rolls-Royceish for them to not purr like the small horsepower engines. Chris Brown in another EPW thread noted it well. P.L.: I do vary my driving route to maximize store window reflections. Doesn't everyone?? I even tend to go shopping late in evening (store open until midnight) as there are fewer pedestrians and curb parked cars to obscure the desired view. . |