| Author | Message | ||

David Gore Moderator Username: david_gore Post Number: 1829 Registered: 4-2003 |

Christopher Carnley has sent me the image of the inverted Merlin engine wood "mock up" - about to leave to drive to Sydney so will prepare the image and put it up this evening. | ||

David Gore Moderator Username: david_gore Post Number: 1831 Registered: 4-2003 |

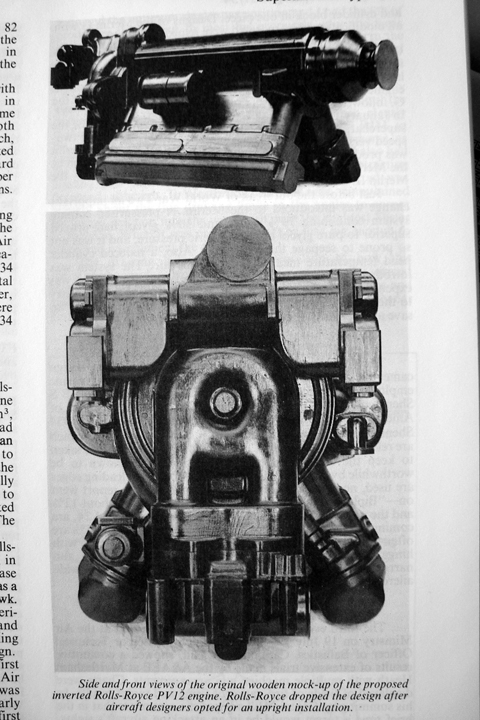

The wooden mock-up below was shown to the German delegation visiting Crewe in 1932/33 as confirmed in the article on the following link: http://www.enginehistory.org/Piston/Rolls-Royce/RHM/RHM.shtml There is some ongoing debate amongst the historians regarding which engines were designated "PV12" and "Merlin"; the following extract is from comments by David Birch from the Rolls-Royce Heritage Trust on 5th January 2014 at the end of the above link: "Although over the years it has been thought that the PV-12 was the Merlin Type A, there is no evidence to support this. No surviving contemporary or subsequent documents ever mentions the PV-12 being the Merlin A. It is interesting to note that the Air Ministry allocated its numbers A109051 and A109052 to two ‘Merlin’ engines with the serials 1 and 3, against contract 231095/33 – the suffix denoting the year that the contract was placed. So, in 1933, the name Merlin had been chosen, and one might think that it must have applied to the PV-12s. But I don’t think it was. At or about this time there was a proposal for a/the Merlin to be an inverted engine, and a wooden model of it was shown to a German delegation that visited Derby. This engine was never built. A time-line on the Merlin’s development, put together in the 1940s, states about the inverted engine ‘This was the first engine to be given the name Merlin’. The first PV-12 was built in this year, followed by a second, they being given the serial numbers 1 and 3. We cannot be absolutely certain that the two AM numbers were originally allocated to the inverted engine, but as things stand at the moment I think that they were. There is no mention in any document I have seen of engines bearing these AM numbers. I would like to disassociate the two PV-12s from these numbers, because in the first report on PV-12 running it says in the introduction ‘It was decided, since this engine was to be produced independently, to name it the PV-12’. No sign that this was a temporary designation until Ministry funding became available. It has to be said, however, that its limited flight development in a Hawker Hart was undertaken against an Air Ministry contract. Had the PV-12 been given the name Merlin in 1933 then it would have been known by it, irrespective of it being privately financed. Also, if a contract had been raised for two Merlins in 1933, then it is reasonable to assume that finance would have been available for them. It seems the PV-12 was just that, a private venture engine."  A special thanks to Christopher Carnley for being aware of this photograph and providing a copy for inclusion in this forum. | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 779 Registered: 5-2015 |

The wooden mock ups were probably used by aircraft makers to mock install in mock ups of the the airframe. GM's competition department sells plastic version of their engines so car builders don't have to heave the real thing around. Boyd Coddington had a plastic 350 small block. The cooling system of the Merlin is quite interesting because it ran on 100% glycol. The RR V8 has a similar design in the cooling department. RR wrote a technical paper on cooling systems before WW2. The paper is used as an authority on piston engine cooling. A problem with upside down engines is of course the engine oil. Once running and being chucked around the heavens it doesn't matter. But when stopped the oil can fill the cylinders and a hydraulic lock will occur as Radial engines do. The requires plugs out and hand pulling the engine over. The De Havilland Gypsy engines (Tiger Moth) were 4 inverted in line engines. Note that the RR V8 engines were designed for 50/50 water/glycol. Not 100% glycol. | ||

David Gore Moderator Username: david_gore Post Number: 1833 Registered: 4-2003 |

Bob, other articles I have read indicate R-R supplied actual early production PV12/Merlin engines to Supermarine and Hawker for their initial prototypes of the Spitfire and Hurricane respectively. There is a photo of an early production engine installed in the prototype frame for the Hurricane in the above link. I have also read unconfirmed speculation the the British pre-WW2 air frame manufacturers flatly rejected the R-R inverted engine configuration due to the time and expense involved in redesigning their airframes which were based on the traditional engine configuration. The German Government reportedly ordered their aircraft manufacturers to use the inverted configuration discovered during the R-R UK visit detailed above and Daimler-Benz solved the problems associated with the inverted configuration with the dry-sump lubrication and, more importantly, mechanical fuel injection which allowed the German pilots to dive earlier and faster to escape their trailing British opponents in a dog fight. Due to carburetor fuel surge problems, the Spitfire and Hurricane pilots had to bank first to load the carburetors with fuel before diving to prevent engine misfiring thus giving the German pilots time to get away from the danger zone between the aircraft. The really interesting part of the above link is the "wild goose chase" within R-R after the death of Sir Henry Royce relating to combustion chamber design. At the time of the Battle of Britain, it would appear the Merlin engine was still subject to serious problems which the article suggests were not completely solved until R-R licenced Packard to manufacture the Merlin and the Packard engineers enhanced the combustion chamber and cylinder head design to eliminate the inherent problems of the original R-R design. R-R designed a flat-head version of the Merlin in 1938 and this engine was the version licenced to Packard. If this is true, the outcome of the Battle of Britain was most fortuitous and the real advantages that gave the Merlin its reputation came with the later introduction of the flat-head Merlin and significant increases in both power output and availability due to increased time between servicing as a result of technological advances. I also read the story of the use of glycol fluids for R-R aero engines whilst researching the Merlin engine in connection with this thread but have been unable to find it again. It appears there were problems with fluid leaks and coolant inefficiency with 100% glycol which lead to the use of the glycol/water mixtures. With regard to the inverted engine cylinder oil filling problem, I have not seen any references to this being a problem with the German Daimler-Benz inverted engines as the dry sump and rocker cover scavenging system meant the bulk of the oil was held in a separate storage tank and not floating around the engine like a radial where the sump was higher than the lower cylinders when the engine stopped rotating. My main interest as a Metallurgist in these engines over the years has been professional relating especially to alloy development, material selection, fabrication, heat treatment and surface treatments. One of the most interesting features has been the parallel development of similar technology in industrialised countries in various countries of the world despite the inherent secrecy needed to protect future competitive advantages. No doubt events such as the German visit to Crewe in 1932 and the Russian visit to the Rolls-Royce jet engine division which involved a degree of espionage would have contributed to this parallel development. The fact that both Sir Henry Royce and Henry Ford pioneered the use of Chromium-Vanadium alloy steels at the same time is a good example; one was producing expensive vehicles for a small market and the other inexpensive vehicles for a large market yet both used the same technology. It would be interesting to know whether there was any sharing of technology between these two legends of the automotive industry or whether they both arrived at the same decision independent of each other. | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 781 Registered: 5-2015 |

On the quiet RR has developed a lot of materials. Which are now in common use. Ford on the quiet developed a lot of machining techniques. Ford mass produced a lot of stuff for other car makers. Fords engineering ability is second to none and better than RR. I take the mick out of Ford as a sport. But look at it this way. When I was reconditioning engines I could put a whole Ford engine together in an hour. The design was such that no shims or faffing about was required. Sometimes when I study RR engines I think its not that good. A mate blue printed a GM 3.3 litre straight six. The result was a very smooth engine that would give a RR six a run for its money. But there again when I took my engine coolant drain plugs out and cleaned them. I noticed the high quality cad plated brass construction. If they had been Ford GM Chysler they would be zinc plated steel seized in the block. Over the years I have heard much criticism of the grossly over engineered aspect of RR stuff. I sometimes think that RR should have been less complicated but still well made. In the 1980s a set of 4 pistons and liners for a Renault 5 engine was about 80 quid. And a set of pistons for a Ford Kent engine were 20 quid. Simple engines promote cheap prices. The story of German engineers mistaking a mock up for an inverted design and designing the ME109 engine from it, is simply not true. The lead times for engines is years from drawing board to production. Any mechanic can draw a V12 engine, the layout is obvious. The details and materials is the hard part. | ||

ChristopherCarnley Unregistered guest Posted From: 86.176.214.110 |

For further interest in the Merlin, one should read the several RRHT books on the engine by Alec Harvey Bailey and "A designer Remembers" by Arthur Rubbra. An elderly highly qualified engineer Colonel Timothy Barrington, who had worked on the old R-R Eagle engine and designed engines et al at Bentley Motors,took the Merlin project to Packard. This was in the form of drawings for the 60 series, the two piece cylinder block, and two stage, two speed supercharger. Packard as mas producers of engines standardised all the R-R drawings, for volume production and introduced the Bendix single point carburettor. Although the V12 Alison engine was every bit as good as the Merlin, it lacked the developed 2 stage supercharger. The Alison had a 2 stage blower, but the second stage was hydraulically engaged. It powered many aircraft during WW2, including the P38 and P40. The German involvement in 1932, comes from several sources, but unfortunately, Elliot one if the PV12 designers, later joked that the inverted mockup was a ploy to confuse the Germans. AS the DB 605, contains many elements of the Kestrel V12 sold to them by R-R, the idea behind the PV12 was obvious to them. The above books detail the coolant problem and that a 90% water mix became standard. A less than close study of the "German Aircraft", in the film "The Battle of Britain", reveals that none of the German aircraft were made in Germany, they are all Spanish copies, fitted with yes you guessed it, R-R Merlins. Which US invention almost certainly allowed the development of the Merlin above the original 740 HP? (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 1835 Registered: 4-2003 |

"Which US invention almost certainly allowed the development of the Merlin above the original 740 HP?" If the answer is what I think it is; another clue is it took several years for the Germans to catch up which they eventually did but the outcome of the war was already inevitable. "The story of German engineers mistaking a mock up for an inverted design and designing the ME109 engine from it, is simply not true." Bob, Something you may have overlooked is the involvement of R-R in making engines for the Supermarine Schneider Trophy seaplanes in the late 1920's and early 1930's. These planes were very aerodynamic but the big engines up front made forward vision very difficult for the pilots. I am in no doubt R-R would have been well aware one of the possible solutions to this problem would have been inverting the engine [the inverted engine mock-up was made in this era] and successful development would have significant long-term benefits. The subsequent story is history; the British Defence Ministry would not fund development of the inverted engine as the result of pressure from the aircraft manufacturers who did not want the expense of having to redesign their air frames, the German equivalent saw the potential advantages of the inverted engine configuration and encouraged further development of the concept. Daimler-Benz went on to solve the basic engine problems of oil locks and fuel starvation by dry sump scavenging and mechanical fuel injection. The concurrent development of the jet engine meant the life of the aeronautical piston engine would be limited and further development of the piston engine suffered accordingly as the military shifted from piston to jet engines during the "Arms Race" that characterised the post-WW2 era. | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 782 Registered: 5-2015 |

Inverted engines for better forward view was well known and obvious from long before the Racing Supermarine planes. The inverted engine is only of use for single engine fighters. Not something like a Mosquito. I think the truth is that the German engineers simply designed the the ME109 engine themselves. A RR V8 is very similar to many other V8s. This fact is often quoted to support the idea that RR copied an American V8. Hitler continual demanded new designs rather than developing exsisting technology. This caused German piston engines to fall behind in the BHP race. In light aero stuff the piston engines still rules. The mpg is better. Larger stuff the jet becomes more economical. I think the first Merlins were 27litres and 1000bhp. Eventually 2200bhp. The un blown version called the Meteor was 750bhp. Also a V8 version called the Meteorite which is as rare as hens teeth. I lived in Greenford Middx next door to RAF Northolt. At school a RAF officer visited for a talk about his WW2 service as a Spitfire pilot. He said when he went full power the acceleration of the plane was neck breaking. The power got him out of trouble a few times. A bunch guys restoring a v Vickers Centurion tank with a RR Meteor engine replaced the magneto with a Jag V12 dizzy. The engine burst into life after 20 year lay up. The magneto got repaired and refitted. There is a surprising amount of Metlins and Meteor engines around still. There's also a marine version of the engine. MTBs had 3 fitted and a massive petrol tank. Not good in cars though. | ||

ChristopherCarnley Unregistered guest Posted From: 86.169.76.152 |

The S6B being a "float plane" was not a "tail dragger", it sat horizontally on the water. Therefore there would have been no requirement regarding reducing the engine nacelle. The Rolls-Royce "R" engine was not inverted, witness the bulges around the rocker covers. One interesting fact is that S/L Frank Whittle used the supercharger compressor of the "R" back to back ,double sided, as the compressor for his proof of concept, and later Whittle jet engines. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 1836 Registered: 4-2003 |

About a decade ago, I bought a DVD compilation that included an old film made in 1942 called "First of the Few" in the UK and edited for the USA where it was titled "Spitfire". The film was most likely intended as propaganda for the British war effort and was largely based [with some major inaccuracies] on the life of R J Mitchell the designer of the Schneider Trophy seaplanes and the Spitfire fighter. The film includes some very rare actual footage of the S4 and the S6 seaplanes in the relevant Trophy races. What I particularly noticed was the probable restricted vision of the sea planes due to the small size of the forward windscreen and the bulk of the engine cowling in front of the pilot. Once the plane was in the air, the pilot only had to be able to see the pylons that designated the race course and did not need the visibility required for a fighter aircraft so the side windows could most likely be used for this purpose. This film is now in the public domain and can be downloaded using the following link: https://archive.org/download/TheFirstOfTheFew/MoviePowderPresentsTheFirstOfTheFew_512kb.mp4 | ||

ChristopherCarnley Unregistered guest Posted From: 86.169.76.152 |

David Niven, "They can,t take the Spits, Mitch!". The German Air Ministry had in 1927, issued instructions to DB to design a V12 of about 30 litres, prototypes were built for the F2, and a later inverted version the F4, which became the basis for the DB600 series. Apart from an "outline", there are no details of the earlier motors, except that the 600 had carburettors. The transition from injectors for Diesel oil to the non-lubricating petrol led to a long standing process of manufacturing refinement. The Brits still have the Schneider Trophy(I believe)that they won after the 3rd success with the R-R "R" engine, over the "W" Napier Lion. (Message approved by david_gore) | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 785 Registered: 5-2015 |

Forward view in tail draggers is limited when taxing on the ground the normal procedure is to zig zag till lined up with with the runaway ready for take off. I wonder if they use a tv camera now. Propellors generally have a max rpm of 3000 rpm. If the propellor is directly attached to the crankshaft this limits engine rpm. Also the thrust of the prop is trying to rip the prop off this loads the crank thrust bearings. 3500ftlbs of torture torque. This is why an automotive engine cannot just be bolted in with a prop nailed to the flywheel. If a gear box is used usually about 1:1.8 then the engine can run faster and the thrust separated from the engine and variable pitch props are easier to install. Rotax make engines like this. These engines run on 100% glycol. A gearbox means that the engine can be mounted lower thus giving better ground manoeuvring visibility. The prop on a plane has to be where it is because of the thrust line. Too low and when power is applied the nose will come up. Too high and the nose will go down. Bunt over and hit the ground. Some mirco lights and autogyros suffer this problem and it has led to a few crashes whilst coming into land. Some tail draggers, the prop almost touches the ground when the plane is level. Longer under carriage struts. Interesting thing about tail draggers is that when the tail is one the ground the prop is not perpendicular to the ground. This causes the thrust to move to one side. When bringing the plane level just before lift off the pilot has to bring the rudder to zero degrees other wise the plane will veer to one side. I think its called the P factor. This is also why twin engines run in different directions. Clockwise and the thrust goes to port. Anti clockwise and it goes to starboard which cancels each other out. There's a lot more to planes than some think. A fly guy told me speed and height is safe. Low speed and height is dangerous and when the speed and height are zero one has either landed or crashed. The RAF Navy ran air sea rescue boats which were like a MTB. There was one in Poole Harbour. The 3 Meteor engines had been replaced with a big diesel. It still goes fast not as fast with 36 RR pistons driving 3 props. I have a great deal of respect for the teenagers who flew fighters in WW2. A description in a book was it's great fun flying a Spitfire or Hurricane but then it's 2 mins of absolute terror. After wards his back would ache from adrenalin. The Spitfire over shadowed the Hurricane. In many respects the Hurricane was a better plane in service due to it's robust ness. The Spitfire was of a stressed skin design. The designers of the Spitfire used this knowledge to design the AEC Route Master bus. The brakes on this bus are similar to the brakes on a Shadow. When I was an apprentice it was standard practice that when the apprenticeship was over they sacked you and got you a job with another company. This was so that methods and knowledge got spread around British engineering. I got sent to CAV. 6 months later CAV got me in at AEC. On the way I learnt about fuel injection and vehicle sparks and CAV gave me a 100 quid for suggesting that if the roller drive chain in a shot blasting machine was changed to a Gates toothed rubber belt then the chain won't keep wearing out every day. I knew about these belts because the firm I was apprenticed to used them on food packing machinery. Exchange of ideas. I shall down load the above film. I love stuff like this. Much better than modern films like Rambo or 4 weddings and a funeral. MODERATOR ADDITION: I have been unable to view this download link as I am using a metered mobile/cell broadband connection away from my unlimited landline connection. As this movie is in the public domain, I am prepared to make a downloadable copy of my DVD version if the linked version is a low quality mp4 format conversion. The master film quality has obviously suffered from wartime restrictions and possibly deterioration in subsequent storage. | ||

David Gore Moderator Username: david_gore Post Number: 1838 Registered: 4-2003 |

Hi Christopher, The Schneider Trophy is displayed at the Science Museum in South Kensington London.  | ||

ChristopherCarnley Unregistered guest Posted From: 5.80.50.42 |

Hi David, I remember seeing it now, along with the "Improved Stephenson,s Rocket", the Whittle engine that "ran away" and exploded, the sectioned and motorised "Merlin", and so many more, too mind boggling exhibits to absorb much of it. Then I "went down the road a bit" to look at Antonio Stradivari,s masterpiece, the ordinary looking "long", version of his violins. It was in store, but the attendant left me alone with it!!!! Made in 1696 and in perfect condition. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 1839 Registered: 4-2003 |

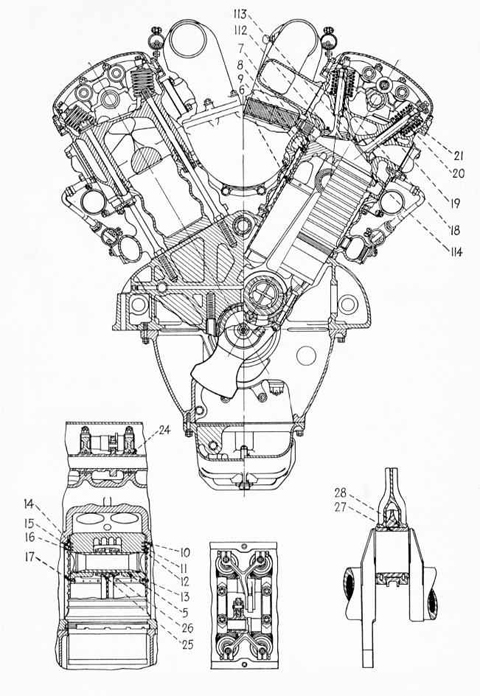

Time for some housekeeping:- My answer to Christopher Carnley's question was the invention of tetra ethyl lead octane booster which allowed the Germans to make 140 octane Avgas to match the fuel available to the Allied air forces however this is incorrect so back to trying to identify what is the correct answer.......has anyone got any suggestions? Christopher has kindly supplied a cut-away drawing of the Daimler-Benz inverted V12 engine as below; the simplicity of the engine is the first thing that attracted my attention.  The Science Museum in London is very high on my list of priorities when I next get to the UK along with the York Railway Museum - reciprocating steam engines especially railway applications are my obsession. I never pass up an opportunity to ride on steam-hauled trains. | ||

David Gore Moderator Username: david_gore Post Number: 1841 Registered: 4-2003 |

Christopher, Might be time for a few extra clues to your quiz question - you have me in a quandary as to which facet of the engine is relevant. | ||

David Gore Moderator Username: david_gore Post Number: 1843 Registered: 4-2003 |

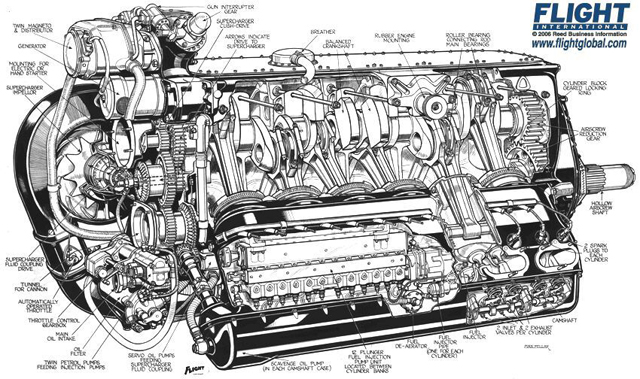

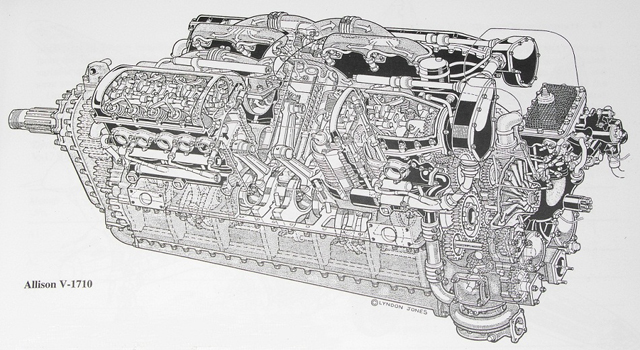

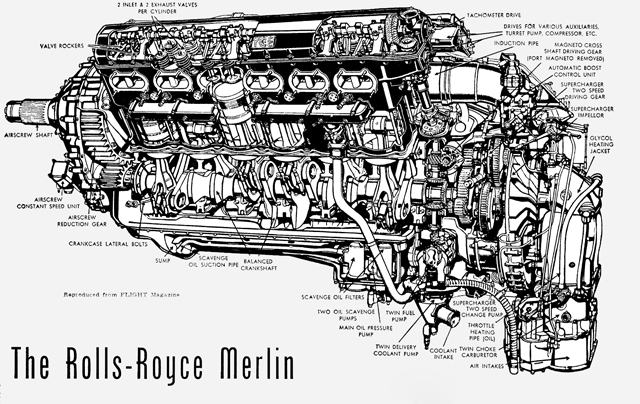

Christopher has sent me some images of the WW2 Allison V12 engine as below and I have included a cut-away drawing of the Merlin V12 for comparison. Christopher has advised me the answer to his question involves the Packard work on the Merlin after they began manufacture of the engine under licence from R-R. Packard V12:   R-R Merlin  | ||

Randy Roberson Grand Master Username: wascator Post Number: 596 Registered: 5-2009 |

intercooling? | ||

ChristopherCarnley Unregistered guest Posted From: 213.122.124.236 |

Randy, Yes, this is a Merlin 66, the charge was cooled as the heat generated by the 2 speed compressor, caused pre-ignition. David, The question that I asked involved the work of the Allison engineers,and is shown in the lower right scrap view. Compare the 1 piece cylinder/crankcase casting of the DB engine to the other two,and you will see that the German foundries were capable of producing a reliable casting where the others had many breakages. Then again,we don,t know if the DB engines were ever subject to the same 100 hr type testing as that at R-R. The casting is in an alloy called "siluminium gamma", which I think is an aluminium casting alloy, but there is no information on that. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 1845 Registered: 4-2003 |

Hi Christopher, I suspect the alloy is actually Silumin which is a specialised casting alloy based on Aluminium and Silicon with other minor alloying elements added to suit the application. The Silumin alloys have good fluidity, low shrinkage and low tendency for hot cracking which are very desirable attributes for a casting alloy. Other properties of particular interest to engine manufacturers would be the low thermal expansion and low coefficient of friction - this alloy has been used for manufacturing pistons and cylinders. The silumin alloys can also be hardened to improve strength and wear resistance by a process known as "dispersion hardening" where the alloy is first annealed and then heated to an appropriate temperature which is maintained for an appropriate period of time to "age" the alloy by the formation of discrete particles with a composition of a secondary phase of the alloy dispersed throughout the parent metal. This dispersion can harden or otherwise modify the properties of the parent alloy to improve the relevant properties of the alloy for particular applications. The "Gamma" description most likely refers to the dominant phase [structure] of the alloy generated by the alloy content and subsequent processing. | ||

ChristopherCarnley Unregistered guest Posted From: 213.122.124.236 |

I checked the name in my old Woldman's Engineering Alloys, there are a group of of them made by Krupp amongst others. Described as a casting alloy for automotive use Mg 0.3%, Mn .05%, Si 12% Al remainder. Makes for a hypoeutectic, easily cast alloy with low thermal expansion. The DB engine has iron dry liners. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 1847 Registered: 4-2003 |

I tried to use understandable language in describing the Silumin range of alloys as they are quite complex and the references available to me suggest a lot of the alloy development occurred in Europe with a significant amount of academic interest in Poland. "Siluminium" may be a corruption that occurred when translating the original Silumin into English or a name given to the Aluminium/Silicon particles dispersed in the parent metal as a consequence of heat treatment - the composition of these particles is quoted as AlSi11 which is an ENAC Aluminium alloy specification ENAC AlSi11 ENAC-4400: www.steelnumber.com/en/steel_alloy_composition_eu.php?name_id=1233 Unfortunately, the metallurgy of non-ferrous alloys is not my strong point so a caveat that I may be in error applies. | ||

Jan Forrest Grand Master Username: got_one Post Number: 893 Registered: 1-2008 |

"Siluminium"? Isn't that the common name for Homo Reptilia? (Doctor Who). | ||

ChristopherCarnley Unregistered guest Posted From: 86.147.219.188 |

(Message approved by david_gore) | ||

richard george yeaman Grand Master Username: richyrich Post Number: 422 Registered: 4-2012 |

I was browsing through e bay the other day and bought a Haynes workshop manual for the Rolls Royce Merlin engine I am waiting for it to be delivered. Richard. | ||

David Gore Moderator Username: david_gore Post Number: 1858 Registered: 4-2003 |

Richard, I bought a similar Haynes owners manual for the RMS "Titanic" - interesting from the construction and operational aspects of the ship but not one I would carry in my toolbox when repairs were required  . . | ||

richard george yeaman Grand Master Username: richyrich Post Number: 423 Registered: 4-2012 |

Hi David imagine pulling up the bonnet of a Silver Shadow at an old vehicle meet and bringing out your Merlin workshop manual, That would raise a few eyebrows around the Barbie. Richard. | ||

David Gore Moderator Username: david_gore Post Number: 1859 Registered: 4-2003 |

Richard, Yes I can and the Devil would make me do it!!!!!!!!! You would need some large tin cans on the end of the exhaust pipe[s] to reinforce the probability of a 27 litre supercharged V12 engine under the bonnet. | ||

Jan Forrest Grand Master Username: got_one Post Number: 900 Registered: 1-2008 |

For the Trekkie at heart Haynes do a workshop manual for both NCC1701 (TOS Constitution Class)and NCC1701D (TNG Galaxy Class). No, I don't own either. | ||

ChristopherCarnley Unregistered guest Posted From: 5.80.54.110 |

Do they show you how to renew the dilithium crystals? (Message approved by david_gore) | ||

richard george yeaman Grand Master Username: richyrich Post Number: 425 Registered: 4-2012 |

Hi Christopher I am sure it dosent it does tell quite a detailed history of the engines the planes and the people who flew and maintained them nearly all of the photographs were supplied by Rolls Royce Heritage trust I am looking forward to reading it over the holidays. Ps it covers 1933-1950 (all engine models) Richard. | ||

ChristopherCarnley Unregistered guest Posted From: 5.80.54.110 |

Hi Richard, I was referring to Jan,s USS Enterprise, NCC1701, the spaceship of James Tiberius Kirk. (Message approved by david_gore) | ||

Jan Forrest Grand Master Username: got_one Post Number: 902 Registered: 1-2008 |

I believe there is a section on the warp drive, including the dilithium control module. |