| Author |

Message |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 528

Registered: 4-2003

| | Posted on Wednesday, 26 January, 2005 - 21:41: |    |

Just a quick update on the repair on our T-Series SBH13247 delivered in Sydney, September 1972. Last year, the final drive crossmember came adrift, and bits spilled all over the road in Canberra. Iíll try to write it up later for a club magazine if there is interest.

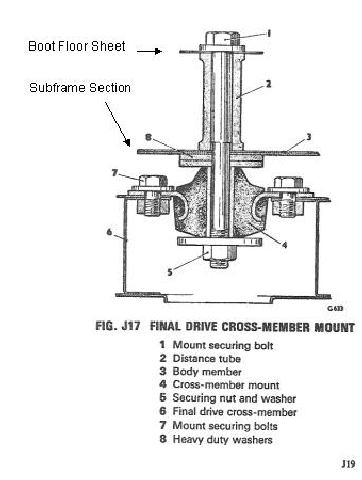

1. This is the standard arrangement as shown in the workshop manual cross section. Note that the load is taken by the boot floor and the small subframe fixed to the bodyshell. The distance tube (item 2) holds it all firm. However, the boot floor and the small subframe section are clearly too flimsy and failed through fatigue over time. Note also the mismatch in the diameters of the distance tube and the washers: very bad design all round I suggest, especially with such small gauge metal. Watch out: this is starting to become commonplace as the cars have now aged.

2. This is the piece of sheet metal which ripped out from the boot floor. Note the complete absence of corrosion anywhere on this car.

3. Here is a Z-piece in place, fitted to strengthen the small subframe supporting the final drive crossmember. It is secured to the floor by a small bolt purely to ensure that the final drive crossmember is correctly located during assembly, and sits above the subframe silentblock mounting. The two large washers (original) can be seen between the subframe and the mount centre left.

Note that there was no welding undertaken on the car. This decision was made so not to introduce new stresses or fatigue sites. The repaired section was simply boxed in to make it extremely sturdy. The Z-piece, the large washer plate in the boot and the distance piece are all held firmly boxed together by the main final drive crossmember mounting bolt. The whole arrangement is held in very securely.

4. Here is the large washer plate in the boot. Both sides are modified with washer plates and Z-pieces.

5. Here is the final drive crossmember as modified in the late 1970s by the Sydney Rolls-Royce distributor free of charge. Note the revised harmonic balancer mounts to Silver Shadow II specification, and the through-bolts and distance tubes boxed in for the silentblock mount. Compare that to the diagram in the workshop manual in fig. 1. It is very much stronger as modified. Despite this, a warning !! The final drive crossmember was showing cracks despite this essential modification. We had it repaired, strengthened and checked for straightness yet again by a subframe specialist in the ACT. Apart from fabricating the Z-piece, this was the only welding carried out.

6. Just to prove that the monster is back on the road.

|

Bill Coburn

Grand Master

Username: bill_coburn

Post Number: 320

Registered: 4-2003

| | Posted on Wednesday, 26 January, 2005 - 22:18: |    |

Richard/ Can I express interest on behalf of most of us. I think this would be a great insertion in Praeclarvm and would be a break from my ramblings. If you agree can I knock something together and clear it with you before it goes to David Neeley? The chamfer tool arrived back OK thanks. BBC |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 529

Registered: 4-2003

| | Posted on Wednesday, 26 January, 2005 - 22:30: |    |

Sure, Bill, no problems. If you suggest a format and start me off, I'll work on it too.

Thanks,

Richard. |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 274

Registered: 9-2004

| | Posted on Saturday, 29 January, 2005 - 07:25: |    |

Richard great mod,i can't wait to get to mine and beef it up as i am more convinced that the mounts are shot on mine as well.

|

John Dare

Grand Master

Username: jgdare

Post Number: 135

Registered: 12-2004

| | Posted on Sunday, 30 January, 2005 - 08:54: |    |

There should be no excuse for owners to disregard or further delay, this important modification, given the foregoing information together with that as provided initially, when I opened this topic on August 8th last year. That thread generated many posts including detailed pics. as provided by R.T ( 24/10) one owner subsequently noting (30/10) evidence of a mount problem within his own car. Once forewarned of a safety related matter we need to respond without any delay, since failure of the kind described usually occurs without notice and in a traffic bound situation with any degree of speed, the consequences could well be catastrophic. In my case, I performed the modification (member and boot/trunk floor) as soon as the issue was bought to my attention, even though (as with my Pitman arm) there was no apparent evidence to reasonably suggest the liklihood of impending failure. Apart from your own safety, there could also be legal liability and Insurance implications, eg "roadworthiness" (?) the former aspect (liability) being raised in a case involving another inherent KNOWN weakness of a structural/ support nature. The question essentially asked, why, in that particular case, no pre-emptive (corrective) action had been taken, if sufficient evidence had already existed to effectively render the issue one of common knowledge. I believe that this provides a lead which should not be ignored. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 562

Registered: 4-2003

| | Posted on Thursday, 10 February, 2005 - 08:38: |    |

John,

Would you be so kind as to post pictures of your own modified final drive crossmember, mounting subframe and boot reinforcement for the record and publication ?

Many thanks.

RT. |

John Dare

Grand Master

Username: jgdare

Post Number: 172

Registered: 12-2004

| | Posted on Thursday, 10 February, 2005 - 10:30: |    |

MODERATOR'S ADVICE

Content of post referred to Author for editing to conform with forum standards.

(Message edited by david_gore on February 10, 2005) |

John Dare

Grand Master

Username: jgdare

Post Number: 175

Registered: 12-2004

| | Posted on Thursday, 10 February, 2005 - 20:45: |    |

I would like to oblige, however to do so would seem to represent an exercise in futility, given the "POOR condition" assessment of my car as offered by one of our regular correspondents who lives "on the other side of the world". I am able to confirm that the modification was performed some years ago (prior to the professional attendance of my present motor engineer) by an "acknowledged" WORLD "Authority"/R-R EXPERT. At least that is what he TOLD me, so although I assume that the work was performed to the highest standard, I now harbour some doubts due to the disparaging comments so gratuitously offered in recent times. As a consequence, publication of details of the work (as performed) would be neither useful or appropriate for instructive purposes within this forum; see "liability" etc. However, in direct response to those critical comments, I can confirm the absence of sludge in my sump, due to more regular oil changes and the avoidance of "short haul runs", these factors appearing not to have been strictly observed by the first (original) owner of some 22+ years. I am pleased to be able to further report that, in accord with previous advice upon this forum, my Shadow diff. gears should "bed in" once "high" mileages are recorded, thereby causing my feint 75kph "hum" to eventually fade into distant memory as do many noises of an irritative nature. Those issues aside, I am beginning to doubt the need for my providing ANY "tech." oriented advice (illustrative or otherwise) given the willingness of others to FREELY dispense and espouse resolute doctrines together with fanciful theories and "findings", seemingly on a "24/7" basis. Moreover, who would generally be able to understand and interpret "my" diagrams and photographs, given the apparent need of visitors to this forum to be "shown/told" (by color photographs) that one needs a socket HANDLE; fixed or ratchet (with or without extension) to deploy WITH an interchangeable "socket" of the type typically used to loosen/re-tighten a fitting such as a Shadow sump (drain) nut. Although I have only recently acquired a scanner, I will perhaps attempt to post a pic. of the "Holden" issue/type FW bearing (if not already discarded) being the bearing that seized when the mature and responsible owner fortunately happened to be driving at (or near) the posted (safe) 100kph speed limit. He is indeed lucky to still be with us. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 563

Registered: 4-2003

| | Posted on Thursday, 10 February, 2005 - 21:07: |    |

I take it that means no. Pity, a few different examples would have been useful.

RT.

ps please be careful to whom you refer as an Engineer, as certain Tertiary qualifications and documented achievements are required for an individual to use that title. |

John Dare

Grand Master

Username: jgdare

Post Number: 177

Registered: 12-2004

| | Posted on Thursday, 10 February, 2005 - 22:08: |    |

Strange is it not. I have a court transcript, whereby a self taught (English car) "expert" declared his occupation (under oath) as, "Motor Engineer", prior to giving evidence. Despite a measure of sniggering from the public gallery (incl. one person who suffered a slipped disc) this was accepted and entered into the record. Since the term was readily accepted by a court of law, I respectfully submit its unchallenged worthiness within the hallowed halls of any "open" public discussion, R-R forum. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 565

Registered: 4-2003

| | Posted on Thursday, 10 February, 2005 - 22:31: |    |

One case cited out of context does not make it unchallenged misuse of title. Presumably, the mechanic was giving evidence in a prosecution, and was not himself a defendant being sued for misrepresentation in the trial you describe. Just ask the professional Engineers' associations and the like. There are plenty of cases of misrepresentation prosecuted in this regard. The fact that the title Engineer is one of the most abused does not make it in any way legal. It does prove that Engineers are tolerant people.

Anyhow, this thread has been hijacked as usual.

I simply asked for contributions of a few photos for a technical article and was bombarded by a whole mix of unrelated file-dump. That was a very peculiar response to a benign request indeed.

Mr Dare, have your Silver Shadow's crossmember, subframe and boot really been modified ? If so, why not show us how ? Unless there are some rude pictures under there, such photos could hardly be at risk in any legal sense. It's like taking a picture of the Sydney Opera House from the Harbour Bridge: do you believe that such photos generally breach copyright or any other regulation ? I think not. |

John Dare

Grand Master

Username: jgdare

Post Number: 179

Registered: 12-2004

| | Posted on Thursday, 10 February, 2005 - 23:07: |    |

No, No, No.. like my Oil pressure gauge installation, its a SECRET!. As I remarked to an associate recently.. why dispense FREE info. for every Tom, Dick and Paddy, given that they often THEN give THEIR friends/associates the impression that it was THEY who first "thought" of the idea, design or procedure. Or they exclaim, "Oh yeah... well I ALREADY "knew" THAT!. As our esteemed U.S visitor, W.Hunter recently indicated, he does not freely disseminate ALL information. Nor should he. Nor will I. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 567

Registered: 4-2003

| | Posted on Friday, 11 February, 2005 - 00:05: |    |

Sounds like my daughter when I turn off the TV for dinner. No, no, no.

A secret oil pressure gauge installation. How pathetic.

Listen mate, this is a technical forum which invites technical contributions. I for one try to put forward ideas and solutions, some original and some from other acknowledges sources.

Unfortunately, some people seem hellbent on trying to hack the more useful solutions offered by others to bits. That is no contribution.

The one topic you have not yet bullied is that of modifying Shadow and SZ windows when they are slow. I give full credit to Richard Vaughan for the stunningly simple concept, and am pleased that hundreds of cars have been so modified worldwide in the last two years alone. However, it's like any optional modification including your hobby-horse spin-off oil filters: if you don't like it, don't implement it, and that doesn't mean that a properly informed owner is a fool not to.

That is club spirit.

It is trite to state that you have a solution, but it's secret and you're not telling what it is. That is no contribution either.

As for implying on this site that you want and deserve money for your advice and will therefore not post it: how rude is that ? It is tantamount to very unethical advertising, and akin to companies that invent computer viruses and demand $29.99 to remove them.

Please, either spill the beans or leave this site alone. Maybe Hansard would make some challenging reading instead.

At least we can be happy that you do not sign off your postings with a Curriculum Vitae American-style. |

Robert Chapman

Grand Master

Username: shadow

Post Number: 170

Registered: 5-2003

| | Posted on Friday, 11 February, 2005 - 23:15: |    |

To aviod any misunderstanding I am not the "motor engineer" refered to by JD.

The person he referers to is I believe Chartered Engineer he uses in the course of his profession who specialises in automotive engineering and is a cosultant to major manufactures on emission testing and safety regulation.

Whilst my qualifications from the UK refer to me as a automotive engineer I am personally very happy to be called a humble mechanic,after all it was good enough for SIR HENRY ROYCE.

I also believe the reverse is true,engineers should not assume they are mechanics.Since their studies are not specific to motor vehicle engineering eg they may well have studied hydraulics but cannot claim to be plumbers,they will have studied electricity but are not electricians.

Two of my personal friends are Chartered engineers, one spent his working life designing machines for the tyre industry and the other was Engineer Commander of HMS Superb and neither would claim to know about their cars many mechanical,hydraulic,electrical,fuel,air conditioning,vacuum,plumbing and emission systems.

The use of the title qualified mechanic requires 5 years technical education combined with in the field practical experience followed by continuous studies thereafter to keep up with new systems . |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 571

Registered: 4-2003

| | Posted on Saturday, 12 February, 2005 - 05:15: |    |

Robert,

Here here. Technical 1ualifications and titles are too often misunderstood and abused.

Back to the thread: I invite contributions and photos of individual experiences on the final drive failure issue before I finalise an article.

RT. |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 310

Registered: 9-2004

| | Posted on Saturday, 12 February, 2005 - 05:43: |    |

Richard it is going to be about two weeks before i can get to mine.

Upon doing the mods did you just carry out crossmember and floor repairs on the N/Side or both while you were at it. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 572

Registered: 4-2003

| | Posted on Saturday, 12 February, 2005 - 05:54: |    |

Pat,

Although the nearside (left) is the one at risk, we had both sides modified. I did not do the job myself as I was not available at the time. Note the plate between the mounting silentblock and the small subframe: it changes the dimensions by maybe 2mm. It is best to make any slight change in the crossmember position the same left and right.

Next time I have a chance, I shall remove one of the two heavy duty washers between the mount and the subframe to lift the crossmember 3mm relative to the carbody. This will make the driveshafts and propshafts better aligned, but the change is minimal I admit. Most other cars I have seen ride maybe 15mm too low or greater at the rear, so a 2mm change is not really significant. Any car with sagged springs, and many do have, would benefit from removing one washer by the way. |

John Dare

Grand Master

Username: jgdare

Post Number: 180

Registered: 12-2004

| | Posted on Saturday, 12 February, 2005 - 06:44: |    |

Thank you RT. Please accept my apologies for this belated response. Rather than review Hansard, I suggest a review of my initial "opening" postings to this forum viz. 1/ "GM" engine conversions. 2/ "Spin-on" oil filter cartridges. 3/ Magnetic oil filter "clip-ons". Although the first topic was sensitive (clearly being open to vigorous debate) perhaps not being of interest to R-R owners GENERALLY, I thought that the other two topics would have been of interest in terms of EASE of maintenence and ENHANCED engine protection. Although I do not expect (as do some) that ALL of my suggestions/assertions or opinions be readily accepted, I do find it strange that I was so vigorously opposed on ALL three topics and usually by the SAME people. It did not take me long to realize that be it pigeon racing club, dog obedience club or first aid/ paramedic group (all of which Ive been associated with directly or indirectly) each club has its self appointed "oracle" or resident "guru" who assumes a "King of the Jungle" mantle and woe betided anyone who expressed a notion or theory that THEY had not conceived, let alone advanced. I can therefore relate to being "bullied" as you say, recalling how I was REPEATEDLY "told" that it was NO quicker (read EASIER!) to change a "spin on" oil filter (see B. Vatters adaptor) than the original insert "cartridge" type, when undertaking such a change upon a "R-R" B60 type engine. To make and vehemently MAINTAIN such a ludicrous assertion (even APPRENTICES laughed!) was "opposition" merely for the sake of, and since I am currently of generous disposition, I hereby DOUBLE my "prize" money to $6000 (SIX) thousand, should anyone seek to prove their claim in a "time trial" supervised by my ENGINEER/s (I do have OTHER marques of cars) or someone of similar standing. If they were to post their "CV" (U.S style) then I would at least be aware of their specific qualifications as opposed to vague references of University "attendance" in days of yore. The other notion of the magnetic "clip ons" (for oil filters) generally attracted dismissive scorn and derision, notwithstanding their current use in high output (600hp?) competition "stock" car engines and HELICOPTER engines, but then what would a L.A.M.E know?. Should I photograph (a la speedo with "clicks") my "special" gauge/mounting, so that everyone will "want" one, only to later hear that it was "they" who FIRST "thought" of the idea?. I think not. |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 311

Registered: 9-2004

| | Posted on Saturday, 12 February, 2005 - 07:34: |    |

Another lot of irrelevant material with nothing to do with the crossmember issue FROM "JOCK PADDY" JOHN DARE.

I feel he is a [Content removed without admitting liability.] to resort to wrecking the safety postings in this manner.

(Message edited by david_gore on February 12, 2005)

(Message edited by david_gore on March 02, 2005) |

David Gore

Moderator

Username: david_gore

Post Number: 410

Registered: 4-2003

| | Posted on Saturday, 12 February, 2005 - 09:36: |    |

On that note, this thread is now closed and I refer genuine contributors to Richard's request for information to assist him preparing his article in the new thread "Final Drive ........ & Boot Floor Strengthening".

Richard helps us now it is our turn to help him |

|