| Author | Message | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 299 Registered: 5-2013 |

and the intermission is related to battery voltage. Hi Folks, This raises a few questions. First, my alternator also seems to work intermittently, which I think gives rise to varying voltage levels, which I think affects my horn. So, is there a minimum voltage necessary for the horn? Is the alternator supposed to allow the voltage to draw down and re-charge in intervals? I assume, based on experience, that there is a minimum operational voltage for the horn, so I think this is really an alternator question, unless I have a high resistance short which is discharging the battery, so my observed alternator behavior is a compensation. Comments? Thanks for the help, Chris. | ||

Bob UK Unregistered guest Posted From: 94.197.122.91 |

The alternator charges continuously. The alternator trickle charges the battery and supplies extra to balance the load as necessary when the lights are on for instance. The horns are worked via a relay. The relay can be heard just as the horn sounds. If the horn button is depressed and the horn does not sound but the relay clicks then there is a fault between the relay and the horn or the horns themselves. If the relay doesn't click then it's either the relay or the wiring from the horn button. The actual switch earths the coil of the relay. Because the steering wheel turns there is an earth brush. Hold button in and turn steering if the horn then works the earth brush and contact ring need cleaning. See electrical in ws manual. The horns fitted are properly loud. The cheapo pip squeak things on modern cars are rubbish. The RR ones can be dismantled and the contacts cleaned. Mine are a minor 3rd apart. Old Mercedes such as the 600 grosser use a major 3rd. Which is more strident but majors sound common. Italians air horns have 3 trumpets which are usually tonic major 3rd and perfect fifth. ( major triad) I shortened a perfect fifth by a semi tone to make all three sound blues. To adjust the RR horns there is a small screw which is turned till the horn uses the minimum amps. They use a lot hence relay. Note batteries must be charged with a battery charger RR recommend 7.5 amps for 36 hours. Don't rely on the alternator to charge a 50 % charged battery from a jump start. The alternator will charge to about 80 % only. This happens because batteries have an internal resistance. So to charge a battery to 12 volts needs more voltage. The alternator goes to 14 volts and holds it supplying more amps as electrical stuff is used, not more volts. Older systems which don't regulate volts well used to over or under charge. To charge to 12.6 volts which is 100% battery charge needs 15 volts. At best an alternator goes to 14.6. To charge to 95% ( which the best percentage for longest battery life) would take a 100 miles of driving. Note I forget the actual voltages, but a 50% charge is not 6 volts. 6 volts is about 10% charge. 11 volts is about 50 %. check lead acid batteries on the web, for the proper figures and explanation. By coincidence I left my jeep lights on all night which flattened the battery, just a click from the starter. So I charged a 15 amps for an hour done the errands. And then charged at 5 amps for 24 hours which finishes at 11 pm tonight. Not recharging properly will slowly degrade the battery. Even letting it go flat for a few hours degrades them. I am careless with lights so I don't take chances.The AA won't continually come out because of careless chaps like me. (Message approved by david_gore) | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 199 Registered: 8-2012 |

You might only need to clean up a few connections. My horns only worked when the engine was running. The battery voltage alone wasn't quite enough to operate them. I took the horns off, cleaned up the connections, and they have worked properly ever since. The connections are in a very exposed position. I only ever use the horn one day a year, and that is on the 16th of June. (The MOT is on the 17th.) But it sometimes gets operated accidentally whilst reversing! Most Lucas horns have a screw adjuster on the back, which you can adjust to get the best sound and most reliable operation. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1133 Registered: 6-2009 |

It is really amazing how man problems with things electrical on these cars often come down to bad ground/earth and/or oxidation on the brass connections. My turn signals had recently practically stopped working when I noticed that if I held the signal stem in position with just the slightest bit of additional pressure they'd at least function. A good spray of Caig DeOxIt into the works has them operating like new. Normally I like to take things apart, chemically and/or mechanically clean the contacts, and apply electrically conductive grease before reassembly. I've never had to revisit a connection so treated. This time, though, I didn't tear into the turn signal/high beam flash switch apparatus. Brian | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 300 Registered: 5-2013 |

Hi Folks, This is all good advice and pretty much what I expected -- age. I think the horn relay is a good place to divide the problem. Can anybody tell me what it looks like or where I'll find it? As far as using the horn, I generally don't, but I can't tell you how often I want to use it, now that I can't! How many times do I need to get stuck behind some moron with his face in his phone and the light has turned green. I think I'd happily trade my horn for a bazooka... (-: Thanks for the help, Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 563 Registered: 5-2012 |

Ha Ha Chris - the American disease - cars not moving off when the lights turn green because the driver is texting, making a ham sandwich or simply watching the tv. My observation of horn use in general is it's usually the blarer of the horn who is venting his/her road rage. Horns should be banned, but then, how would we in America ever get through the traffic lights. Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 301 Registered: 5-2013 |

Hi Geoff, Most drivers use their horn as an editorial comment, not a warning device. They use their horn, when their brakes are actually the correct response. When I blow my horn, it is, as it was intended, a warning that you are in danger, so put down your phone and pay attention to the job at hand, while I load this shotgun. (-: Most drivers I encounter have the mistaken belief that they are entitled to the path in front of them; they don't realize that they are required to yield forward. We have endless reports of road rage because "that guy cut me off!" which is a meaningless complaint; the driver in front has an unrestricted right-of-way. Geeze, don't get me started ... Chris. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 201 Registered: 8-2012 |

Gentlemen in Rolls-Royces would never resort to anything as vulgar as a motor horn.  The proper use of the horn is as a defensive warning. For instance when travelling along a narrow country lane you might sound your horn when coming up to a blind corner, to warn anybody around the corner that you are there. Or on the aproach to a hump-back bridge when you can't see over the top. The problem is that nobody uses their horn like that these days, and if you do, everybody wonders what your problem is, and what they've done wrong. BTW The horn relay is in the relay box at the back of the engine compartment. I hope you can hear it clicking because if not it will take you 2 hours of dismantling to get to it. If the relay is not clicking, check the contacts on the steering wheel first, as they are more likely to be faulty than the relay. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 302 Registered: 5-2013 |

> The proper use of the horn is as a defensive warning Exactly! "I'm sorry, but you might be in danger as a result of circumstances beyond my control." It also comes in handy if you want to get the attention of cute babes on the sidewalk, but I repeat myself. (-: Chris. | ||

Bob UK Unregistered guest Posted From: 94.197.122.85 |

I the other day was approaching a junction with a parked van on it, which obscured full view, it was dark and I could see headlamps moving behind the van so as I got near I used the horn to warn the hidden car I was present. The car pulled out behind me and sounded it's horn flashed its lights and generally made it known that he thought I was disrespectful to him because I sounded my horn. The right of way is not in the highway code(UK). Right of way makes a good epitaph on a gravestone. I don't have near misses only delays. I get there when I arrive. If the time is important then I leave early. My bands drummer always turns up on edge because always late and driving too fast it takes him 30 minutes to settle down. Not good for playing well, and his car has lots of digs and scrapes Also headlamp flash means nothing in the highway code. Bad earths are par for the course with ALL old cars. I fixed a Ferrari today the air con clutch wasn't working because of a bad earth. So common. Red 308 and the owner had a moustache. Higgins had the right idea, drive a RR. I will find my battery notes with the accurate figures, and battery charger voltages and put a posting in miscellaneous. Because this information is little known, mechanics at tech school are briefly taught about batteries and then forget the lot. (Message approved by david_gore) | ||

Jan Forrest Grand Master Username: got_one Post Number: 714 Registered: 1-2008 |

When the dipstick kraut tried a 'U' turn in front of my Shadow in Belgium I didn't use the horn, but relied on the brakes. Still caused €hundreds in damage to his Audi! Oh dear. What a pity. Never mind! The Rolls? Nothing visible. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 303 Registered: 5-2013 |

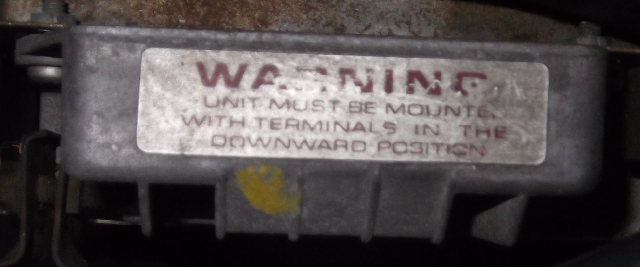

So, this thread has drifted rather far afield, and as amusing as it is, I'm still trying to solve my intermittence problem, and I think my best approach is to divide the problem at the horn relay. Does anybody know where it is or what it looks like? Is this it? If this is not the horn relay, what is it?   Thanks for the help, Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 564 Registered: 5-2012 |

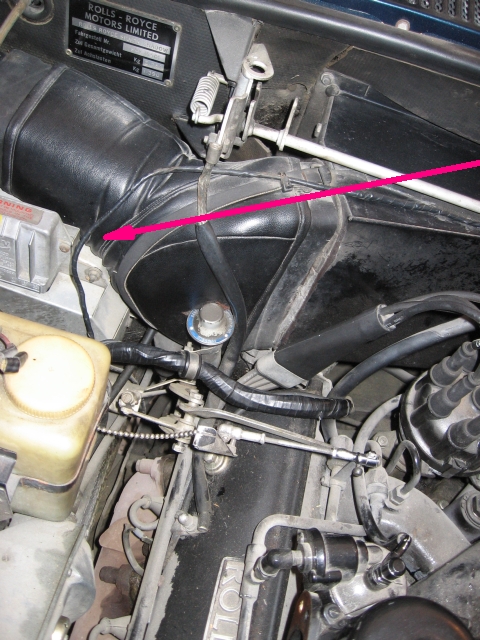

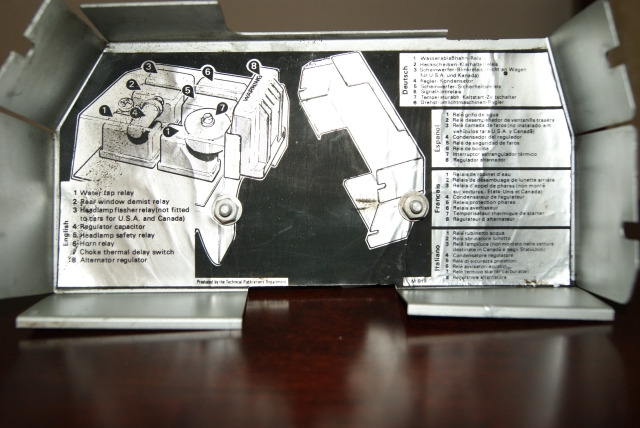

Chris It is the voltage regulator, the device that keeps the voltage constant whatever revs the alternator is doing. The following is from my car, a 1974 SY1 - others may differ. The horn relay is in the aluminum box that it is bolted to.  This picture shows the position of the regulator, just in front and beneath the passenger side (US) heater duct.  This is a picture shows the regulator and relay box with the heater duct and windscreen wiper motor removed. The horn relay is in the box.  The inside of the relay box when it has been removed from the car. The horn relay is number 6. You can now see why Bob Reynolds says "I hope you can hear it clicking because if not it will take you 2 hours of dismantling to get to it." Here's hoping you can hear the clicking, although if you do have to go in, the job is not a difficult one, just time consuming Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 304 Registered: 5-2013 |

Hi Geoff, Thanks very much for the help. I can tell you that when the horn does not work, I do hear a click, but that only means that the relay thinks it is doing its job; I can't tell from that what the problem is, so I think I need to get in there with a meter and measure some things. Additionally, my windshield wipers are exceptionally weak, so I think there is something else much more significant happening and it is happening right around there... Thanks again for the help, Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 565 Registered: 5-2012 |

Hi Chris Regards the slow windshield wipers, as you say, it could be due to low voltage/electrical problems. However, another possible cause is the wheelboxes gum up over the years and become very stiff. This is a common fault on these cars. When you get round to this problem it is worth removing the wiper motor and pulling out the cable. You will then be able to test how stiff the wheelboxes are. I cured mine by running some WD40 down whilst constantly rotating the wheelbox spindles with my fingers. It took about half an hour. When completely free, I ran some light lubricating oil down. No problems since and it saved me from having to remove the top roll to remove the wheelboxes. Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 306 Registered: 5-2013 |

Hi Geoff, Once again, exceptionally good advice. I foresee a huge engine bay project in my near future -- probably March. You just can't believe the weather in Sacramento in March. It will take me until then to plan it. Bob UK mentioned an electrical fan conversion, and I'm quite keen to do that, among other projects... Thanks for the help, Chris. | ||

Bob UK Unregistered guest Posted From: 94.197.122.83 |

If the relay clicks then test at the horns. If there is power to the horns, take the horns off. Connect horns direct to battery with an ammeter in series. If the horns don't work but consume current then turn small adjuster out until horn sounds turn until minimum amps is showing. Or just take a guess. If the horn doesn't work and uses no amps then turn the screw in until minimum amps. Or guess. Relays are reliable and ones that click are almost guaranteed to switch correctly. So if I hear a click I take it as working. The wheel boxes do go stiff, the spindle gets tight. To oil them either take the cable rack out or build funnels around the spindles and fill With engine oil and work the motor. The oil will eventually run down the spindle and end up on the gear wheel and rack. I prefer to remove racks and lots of grease and oil. Once done it lasts for years. The system is used on lots of brit cars and is called a Lucas Smith's cable rack. The correct colour for the horns is gloss black. They are behind the left hand front bumper just in front of the left front wheel. Remove inner plastic mud guard for access lots of self tappers. Fit New self tappers. (Message approved by david_gore) | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 311 Registered: 5-2013 |

Hi Bob, > ... turn small adjuster out ... What is the "small adjuster" adjusting? Volume? Pitch? Resistance? Simply current consumption? Thanks for the help, Chris. | ||

Bob UK Unregistered guest Posted From: 94.197.122.81 |

The big nut and slotted screw (if so fitted) is the armature stop and shouldn't be adjusted. The small screw adjusts the tension on the points. The pitch is fixed and cannot be altered. The correct method is to put an ammeter in series, 20 amp range will do. Set at minimum amp consumption as I said before. Refer to workshop manual. Chris please note that the reason others and I know stuff like this is because we read manufacturers information. It saves and enormous amount mistakes. Often I read workshop manuals and another penny drops. (Message approved by david_gore) | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 312 Registered: 5-2013 |

Hi Bob, > ... reason others and I know stuff like this is because we read ... And this is why we ask you questions and listen to your answers. I didn't know about the adjustment, but I would have learned about it had I read: https://en.wikipedia.org/wiki/Vehicle_horn, which is not manufacturer's publication, but quite good nevertheless. I didn't know there were any adjustments on a car horn; I thought it was a static component. I didn't even think to go looking for an explanation of something that I thought was trivial until you mentioned that it is simple, but non-trivial. In my defense, I don't read as much automotive publication as I'd like to because my brain is full. That happens keeping up with computers, software and the assorted technology of today. There is not much room for the technology of yesterday, which is why I participate in the forum. I don't know all the answers, which is not to say that I don't know some of the answers... Thanks for the help, Chris. | ||

Bob UK Unregistered guest Posted From: 94.197.122.85 |

There is lots of room in one's brain for basic stuff such as how electric bells, buzzers, horns and wind tone horns work. I find that when reading manuals people assume stuff and skip paragraphs. An example of this is alternator testing. Many years ago I was testing an alternator in situ and I hadn't fully read the makers instructions. I saw a picture of a volt meter connected up, and went my own way from there. If I had fully read the section I would have found out that by removing a small rubber bung and inserting a screw driver, so that the field is sorted to the alternator case. If the volts go to 15v then the alternator is ok and the external regulator is faulty. A clever bit of design which is not obvious unless the book is read properly. GM. Because a work shop manual is technical and not a newspaper artical I read the instruction more than once and reference my understanding to what I am seeing on the car, if it doesn't match my expectations I must be misunderstanding something. Back to horns. The horns are under the lhf wing. Connect a test light to the horn and check for power when the button is depressed. If no power check backwards to the relay. Check the wires and connectors of the left of the radiator. Black is earth or neg. Blue white is main beam blue red is dip. Red is side lights. Green white or green red is indicators. The horn wiring may also be in this area. I can't remember the colour of the horn wires but mauve springs to mind. Google Lucas wiring colour codes. Because all Lucas wired vehicles use the same code. The blue white wire on all Lucas vehicles is main beam etc etc. Also reference the wiring diagram chapter M. To read this type of theoretical wiring diagram, notice that at the top and bottom is a guide to where the component is. Dotted lines around groups of bits means that the group is one component. The wire that appears to goes around the outside of the drawing is not a border, it is earth. Black. Once the relevant bits have been found draw the circuit out on paper with colour of wire, size and type - cotton or plastic - c or p -. This helps quickly identify which wires do what. And which wires have been retro fitted, if fitted. (Message approved by david_gore) | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 313 Registered: 5-2013 |

Hi Bob, > Google Lucas wiring colour codes. Because all Lucas wired vehicles use the same code. This is more valuable than I can tell you. The manual has about a dozen wiring diagrams for various time periods and configurations and application (Theoretical vs Practical) I have a diagram that I use, but god only knows if it is the right diagram... It is the fear that it may not be the correct diagram that has kept me from diving in and sorting out a few problems I have which may or may not be electrical problems. I found this: http://www.dimebank.com/LucasColours.html and it appears to be comprehensive, but I can't gauge accuracy. Maybe you could review it... Thanks for the help, Chris. | ||

Bob UK Unregistered guest Posted From: 94.197.122.71 |

Lucas wiring information www.peterrenn.co.uk This guy explains it in colour. (Message approved by david_gore) | ||

Bob UK Unregistered guest Posted From: 94.197.122.78 |

Dime back is sort of right. But has omissions and small errors. Try to find a UK based one. The proper Lucas one has a theme. Eg all Brown are unfused live all the time. All mauve are fused live all the time. Green are fused and ignition switch controlled. All red are side lights all blue are dip or main. White wires are ignition controlled and are engine related Eg white with red tracer, starter solenoid. Tracers Eg blue wire with black tracer, because black is earth, blue with a black tracer means main or dip and it's on the earth side. ( in this case it's the wire from the headlamp flash, the switch earths the relay). In the old days to steal any British car all one had to do was to bridge the two fuses in the fuse box and press the rubber button on the starter solenoid. To make it even easier Lucas fitted spare fuses in the box. A spare fuse fitted nicely between the fuses to bridge the circuit. Why they bothered with key ignition is a mystery. Once one has figured out the logic of the colours then even without looking one can predict what the colours should be. Note that some Lucas systems have a bit of Brown wire that connects the battery to the electrics, except the starter. This bit of wire is special because it's a fusible link which should a major short occur in the power supply to the car. It blows like a fuse. On the electrical circuit diagrams there is no mention of one. Practical diagrams show loom plugs and numbers of terminals. The look like the actual loom on the car. This is used to identify where the wire is actually on the car. The theoretical is about how the bits are connected and how they interact with each. Note find the theoretical drawing for your car lhd. On the last sheet on the right is the actuators for the heating and air con. The water tap actuator has three wires earth, tap open and tap shut. This means that the tap is on or off. The actuator has six terminals, when used for flaps all the terminals are connected because the actuator has five positions. At first sight one would think that the tap would have more positions to control temperature. But the drawing shows otherwise. These circuit drawings are invaluable for figuring out the little nuances of these cars I wish the drawing was in colour. I done one for a Mk2 jag in colour, for a college project and the college kept it as a teaching aid. It took hours to do. (Message approved by david_gore) |