| Author | Message | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 464 Registered: 4-2003 |

Last night I changed out the steering rack on my Turbo R, HCH20037. I have attached a photo of the leaky one just before I removed it for those who have not seen this chronic problem. The leaks are clear to see. The oil was certainly steering fluid and not engine oil by its colour and smell. With the rack on the bench, if you squeeze a convoluted seal you can see the leaked fluid sloshing around inside through the steering takeoff bolt holes. Inside, it is completely awash with fluid. These racks ase supposed to be filled with lubricant in there (later cars and upgrades like mine use grease: I think all rebuilds use grease nowadays). Only if the PTFE seals leak can fluid get in. The trouble is that a slow leak will be undetected for months until the chamber is rather full and fluid has to come out somewhere. I was topping up the reservoir every few days recently. Even when it was first fitted mid last year, that rack did consume oil at a measurable rate. Thank goodness my honourable UK supplier covered the parts and shipping under warranty despite the elapsed time. RT.  | ||

Larry Halpert Prolific User Username: larry_halpert Post Number: 33 Registered: 9-2003 |

What is the exact design flaw that causes these racks to leak so quickly? Why do other car racks of the same design not leak? I can't imagine the pressures are higher than all other makes of cars, or the seals are beefier in other cars. Can we apply any ideas (or seals, or seal material) from other cars' racks? Larry tbird@consultant.com | ||

David Gore Moderator Username: david_gore Post Number: 338 Registered: 4-2003 |

Richard, Have you observed any scoring/scuffing/pitting or other mechanical damage to the rack shaft where it passes through the seal? When you remove the boot and drain the leaked fluid; do you see any evidence of dirt/metallic residues in the boot and/or oil? Do you still have a U/S rack shaft and do you have access to a local technical college/university/metallurgical lab who can hardness test the shaft in the seal area? If so, I would really like to know the surface hardness of the shaft in Rockwell "C" scale or Vickers DPN/HV reading. I have an inclination as to what is causing the problem from my mining days but need to clarify a few things!! | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 465 Registered: 4-2003 |

David and Larry, On the rack I have just removed I shall not do any analysis myself. It is sitting on my back verandah ready to ship back to the UK today. As a warranty exchange, I may not open it up for that reason. Shame: I have access to the test facilities you mention nearby. Maybe foolishly, I decided last time to buy an exchange rack. The repair components cost the bulk of the price, and exchange units are bench tested and guaranteed. Given that I drive the car daily, an exchange job in less than two hours makes more sense than a day-long rebuild with risks of further parts requirements. I rent workshop space by the hour, especially in winter, so any demurrage would be crippling. It makes no sense leaving the car on a hoist and paying hundreds a day while waiting for spares. The last rack I put in my car was not a warranty replacement, or rather, stupidly I didn't have the guts to claim. I opened that one up and dismantled it partially, then reassembled it and returned it as the exchange core. It was visibly perfect in every respect. No scoring, no wear marks, no dirt or sludge, no metal particles whatsoever. There was no play anywhere, and the steering felt like new. Just leaks. I am convinced that the PTFE seals are simply not fit for service. What is annoying is that seals are such old hat these days. That Crewe and the repairers have not sorted this out is quite astonishing. There is any number of seal specialists out there who will make one-offs or production runs. Other makes of cars don't suffer nearly so badly, and the manufacturers found solutions years ago. The Rover SD1 uses a very similar centre-takeoff rack. They leaked early on, but even good old Rover sorted that out very quickly before warranty claims could damage that company even more than it was already. Atlantic Enterprises in the US offers a lifetime warranty on its R-R racks: I'll bet the guys there have cracked it. Unfortunately, they only do LHD. They do have a UK partner for RHD which I shall try when this rack needs its annual replacement next year. I worked in the mining industry myself by the way. In Central Queensland, we had several funny little men visiting to cure seal problems of hydraulic equipment on draglines, drills, shovels, washplants and loading systems: they always had a solution. Having said that, just a few litres of spilled fluid in a tough mining environment was not of any concern. On a car, a drip is too much by comparison. Sorry I can't do more analysis this time, but I am convinced that it is a pure seal deficiency causing all this. RT. | ||

Robert Chapman Grand Master Username: shadow Post Number: 123 Registered: 5-2003 |

David, Please forgive me if I am stating something you already realize,the rack shaft on this design of rack does not pass through the seal in the same manner as for example a Jag rack where the seals are stationery. In this design the seals are fitted to either end of the rack shaft and move with the shaft sealing against the inside of the rack tube. In many cases the seals do not seal because this tube is scored,bent longditudinally or oval on the inside dia. Obviously in this design the condition of the tube is critical to successful sealing. In my opinion it is better to have the seals stationery sealing against a much more ridged shaft than trying to seal against a thin wall tube. In other cases the oil comes from the lower pinion seal into the space between the rack seals,leaking out of the centre of the rack and boots. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 127 Registered: 9-2004 |

Robert I agree with you 100%. However the wear in my opinion in the first instance is caused by my comments on wheel dynamic balance. second year apprentice. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 467 Registered: 4-2003 |

Just before shipping the rack back, I tried to put some more fluid down the bolt holes into the sentre cavity, ie outside the seals. None would go in because it is 100% full. Don't tell me that wheel wonbble caused the seal failure. This car has absolutely none. It's as smooth as a Citroen. Furthermore, every two years it has a very stringent compulsory roadworthiness test. They check everything. In the suspension department they have computerised equipment to test wheel alignment, drivetrain and wheel balance, tracking, shock absorbers and lots more. I once had to show them the workshop manual, remove the front wheel grease caps, and prove that the bearing end float is to spec and not a sign of wear. If the seals fail due to the tube metal type (ie porosity, abrasiveness or the like), then why don't they change to a seal which is immune to that ? They exist for heaven's sakes. Better seals are available which tolerate wear and scoring too. These seals seem incapable of sealing a rack in perfect condition for long. I look forward to the report from the repairer. Maybe the seals were damaged during assembly. If I had a spare rack I would tinker around. Perhaps I should have bought the rack core for £250 and had a go. I was stuck with no option but to exchange the rack the last two times as time on the hoist costs money. You soon lose the saving of a DIY rebuild after a few hours idle on the hoist: it should be cheaper and safer to buy an exchange unit. One time I changed the rack in the common car park at home. The neighbours exploded. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 128 Registered: 9-2004 |

Richard i am not telling you,i am sugesting just one of many possible remidys for extended rack life. | ||

John Dare Unregistered guest Posted From: 144.138.194.190 |

I know of several owners who drive a variety of vehicles, other than "R-R/B", being vehicles fitted with power assisted rack type steering and which are less expensive than "R-R/B". Such vehicles, of varying weights and sizes, whilst not abused, are for the most part, neglected in terms of service, excepting the obligatory oil changes etc. These owners would never consider a shock absorber check nor (despite my urging) change their coolant or hyd.fluids at the commonly accepted intervals. Even tire pressures are only corrected (with some reluctance) should the tire appear to "look' flat. Not suprisingly,they are only mildly aware of wheel balancing when new tires are fitted every few years or so. In these instances, I can report that such owners do not experience steering rack leakage or if they have,or do,then the extent and frequency thereof is relatively insignificant when compared to "R-R/B". I trust that this may assist informed viewers to reach their own conclusion regarding the assertion that wheel imbalance is a causative factor in relation to the issue at question Moderator's comment: If my thoughts on the possible cause of the leaks is correct; it is probable vibration transmitted through the steering linkage COULD exacerbate the problem (Message edited by david_gore on December 02, 2004) (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 340 Registered: 4-2003 |

Thanks Everyone especially Robert as I was not aware of the rack design used by R-R[never got past DRH14434!!]. I think Robert is on the right track regarding ovality/rigidity of the bore and the moving seal. The question for our polymer experts is what material can maintain its hardness [and hence abrasion resistance] at the operating temperature of the rack yet have sufficient flexibility to tolerate any distortion/irregularities/expansion in the cylinder bore. For what it is worth, I think the leakage may be due to differential expansion of the seals and the tube bore at operating temperature; the I.D. of the thin-wall tube expands slightly more than the O.D. of the seal which has not "softened" sufficiently to expand to the larger I.D. under pressure from the steering pump fluid thus allowing fluid to weep out into the boots. Vibration from the steering linkage transmitted to the rack could also be responsible by causing the rack to oscillate thus creating intermittent local loss of contact between the seals and the bore with consequent fluid leakage. Use of heavy-wall tubing for the cylinder to constrain thermal expansion is obviously not practicable so seal specification is the only avenue for investigation. Richard, if the opportunity to play with a rack presents itself; I would like to see the outcome of fitting a softer seal or one which has a higher co-efficient of thermal expansion than steel to try and maintain better contact with the bore at high temperature. Over to everyone for comment please. | ||

Robert Chapman Grand Master Username: shadow Post Number: 124 Registered: 5-2003 |

Patrick, Thanks for your munificent comments. But what do you mean by the words in the last line of your post"second year apprentice" I do not understand. | ||

John Dare Unregistered guest Posted From: 144.138.194.81 |

On 2/12 at 2-36, I stated that I was aware of power/rack type steering in cars which probably suffered wheel imbalance (due to neglect/ignorance etc) and yet such cars did NOT display rack leakage of the order commonly experienced by "R-R" owners. This drew the observation that vibration (such as wheel imbalance)"could" exacerbate the problem of rack leakage. Well, yes..it COULD, but it does NOT appear to DO so, given the circumstances mentioned in my post, such being based upon day to day field observations. If on balance (pun unintended!) of probabilities, wheel imbalance DID cause (or aggravate) rack leakage, then my point was that this would logically be reflected in general leakage within a variety of misc. makes/models of cars AND with a frequency and extent similar to that observed in "R-R/B" vehicles. Moderator's Comment: John or anyone help please - is the R-R/B rack from the "parts bin" of another manufacturer or a unique R-R component? (Message edited by david_gore on December 03, 2004) (Message approved by david_gore) | ||

Larry Halpert Prolific User Username: larry_halpert Post Number: 34 Registered: 9-2003 |

You can see all the rack reference numbers on the Atlantic Enterprises website, and they list a different number for Bentley, as for Rolls. Both numbers don't appear on any other make of car. http://www.atlantic-ent.com/page16.html The point is that other manufacturers use the same DESIGN STYLE of seal rubbing against tube. Why don't those particular cars leak? What seal material do THEY use? Thicker guage tube less prone to deform? Closer tolerance to inner tube, so less of a reach for the seal? Maybe an email to Atlantic Enterprises with the question of why Rolls/Bentleys leak, and not other manufaturers - would get us an answer. Larry tbird@consultant.com | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 470 Registered: 4-2003 |

David, As far as I know it is a special not shared with any other vehicle. There was a lot of hullabaloo about the uniqueness of this rack at its release in 1977. The centre track link takeoff is especially good for bump-steer behaviour, and was indeed a little unusual. Very few large cars at the time used rack and pinion steering. BMW and Benz persisted with conventional steering for decades longer. The racks were not manufactured by R-R: there were two or three sub-suppliers over the years and they all had problems with them. I don't know who actually designed these racks (Crewe or subcontracted), but Crewe apparently owns the design. The Saginaw steering box (don't mention that lever thingo which hangs off it though) which the racks superseded was very well sorted out from day 1. It was an adaptation for the Crewe application and not a new design, needing not much more than that special dreaded lever thingo hanging off it. Perhaps the lesson is to be learned easily here. As any engineer will tell you: new design, new unforeseen problems. | ||

Robert Chapman Grand Master Username: shadow Post Number: 127 Registered: 5-2003 |

Hi Larry, I think the difference here is the other designs DONT move the seal backward and foreward along the tube,the seal is stationery EG Jag racks. The seal is fitted into an alloy houseing about 8in long,this is fitted and stays stationary inside the tube,sealed on its outside dia by o rings. This provides both a housing for the main rack shaft seal and also a support bearing to keep the seal concentric to the rack shaft. I believe that neither the RR design nor the way it is mounted are ideal and depends for its service life on the condition of the parts assembled and the quality of the seals used. | ||

Bill Coburn Grand Master Username: bill_coburn Post Number: 287 Registered: 4-2003 |

A small anecdote. Well I remember the very first rack and pinion steered Shadow that came to our shores. The then York Motors workshop manager attended by his sales colleagues rushed down to Customs to view the arrival. The end of the container was flung open and there on the floor was the entire oil supply for the steering system. And from there it seems things have improved little. | ||

John Dare Unregistered guest Posted From: 144.138.194.170 |

David,Larry & Richard. It is probably irrelevant, but I seem to recall the original "R-R" racks being made by "Burman" or similar sounding name. If that co. was the manufacturer, it would be interesting to know what racks they made for other makes/models etc. However, as R.T observes, the racks were made to Crewes specification, thereby causing the issue of design versus manufacturing fault/inherent defect,to remain open to question. (Message approved by david_gore) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 472 Registered: 4-2003 |

John, The trademark on the latest rack is certainly a B with sort of flames leading backwards, the trademark for Burman, and the Crewe part number UR71818 stamped on the same plate. This was the third supplier I believe. | ||

Larry Halpert Prolific User Username: larry_halpert Post Number: 35 Registered: 9-2003 |

Robert, so there are no other cars whose racks use this moving-the-seal-along-the-tube design? Larry tbird@consultant.com | ||

Robert Chapman Grand Master Username: shadow Post Number: 128 Registered: 5-2003 |

Hi Larry, I am reluctant to say categorically none,as there may be some motor manufacturer using it that I personally have not seen. But to the best of my knowledge I dont think there are. I will make enquiries tomorrow from the companny that overhauls all of our RR racks,and get their opinion on the causes of failure. I must say in faireness to them we have not had a single rack come back in over 5 yaers of useing their services. I think it could reasonably be argued that the sliding seal design is used in many hydraulic apllications,the simple brake wheel cylinder for instance,but I think the difference is that the housings are usually much stiffer and probably of more relevance, shorter. I would like to get Richards opinion on the hydraulic side of things. | ||

Wayne Shearman Unregistered guest Posted From: 203.58.1.12 |

Dear Rack people, If it helps, Page 100 of Graham Robson "RR and B Volume 3" and I roughly quote "The componemts came from Burman, and there were some similarities with their ROVER 3500 (SD1) installation, however in the RR, there were track-rod takeoffs in the centre of the rack, with long links to steering arms themselves and 3.5 turns lock to lock." Wayne (Message approved by david_gore) | ||

John D Unregistered guest Posted From: 144.138.194.13 |

Thank you Richard. I am concerned about your indentication of "flames leaning backwards", within what appears to be a stamped trademark/corporate logo etc. Was someome was trying to tell us something? (J.G.Dare) (Message approved by david_gore) | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 133 Registered: 9-2004 |

Hi Larry,This a pix of the Audi 100 power rack been around for twenty odd years. This car and rack has travelled 300,000+ miles. Look at the angles of the track rods,this car from our records has been balanced off the car. There are other marks that have the same design with no probs. Test pix  | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 134 Registered: 9-2004 |

Robert five years, thats better! Still sugest a great many faults are down to neglect of shockabsorbers,steering geometry, wheel balance proceedure with excess loading on the rack seals etc. | ||

Robert Chapman Grand Master Username: shadow Post Number: 132 Registered: 5-2003 |

Patrick, Are you sure that car has ONLY done 300K? Look at the state of it!The left hand track rod is very rusty and the high pressure hose/pipe looks rusty enough to blow any second,not roadworthy(MOT) surely. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 137 Registered: 9-2004 |

Hi Robert,Yes 300,000+ the car has not been used for years. It is waiting for a new porsche model 965 to be made hence the keeping of the reg plate. Note the lighter vehicle for the type of rack design. Not a two ton car like the SS2.  | ||

Robert Chapman Grand Master Username: shadow Post Number: 134 Registered: 5-2003 |

Patrick I take your point about the weight difference and the design; perhaps this could also be a contributing factor. This car looks likes it is in a very rural area, I thought by the rust you may be by the sea. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 141 Registered: 9-2004 |

Robert,just to confuse the issue with the loading aspect on the rack between cars. The Audi is front wheel drive ie torque steer loading on the rack. Maybe more dampening to stop leak faults,your thoughts please. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 146 Registered: 9-2004 |

Robert. Years later and no torque steer and here we have a power GM rack bone dry and 100,000miles ,note the strait line arms as the SS2 but no Block fixing of track rods,any thoughts welcome.  | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 485 Registered: 4-2003 |

Here is the B logo with flames. I hope, as JD points out, it is not an Almanac.  | ||

David Gore Moderator Username: david_gore Post Number: 344 Registered: 4-2003 |

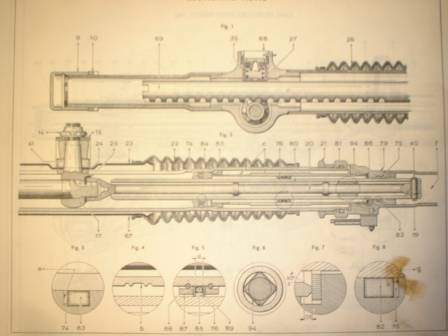

Gentlemen, Forgive me for intruding but the "flames" on the leading edge of the "B" appear to be an artist's rendition of steering rack teeth to create a corporate logo - unfortunately the picture size does not allow me to enlarge it to see it in more detail. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 487 Registered: 4-2003 |

David, You are quite correct about the logo. You spoiled a nice tall tale though. RT. | ||

David Gore Moderator Username: david_gore Post Number: 346 Registered: 4-2003 |

Sorry about that Richard - pedantry prevailed!! However please indulge me with the following observation:- Rather than flames, the artistic rendition is more in keeping with hands clasped in prayer seeking freedom from leaks. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 166 Registered: 9-2004 |

This confirms my thoughts on the premature leaks to the racks,caused by my above comments. Sorry Richard but to-day after strolling up to the garage i was confronted with a FWD Ford Freelander in for some repairs. Upon glanceing in the engine bay i was amazed to see that the steering set up was indeed the centre point power steering similar to the SS2 etc. My point is if the racks were of weak design they would certainly not fit them to a rugged type of FWD vehicle? Your thoughts welcome.  | ||

Greg Churm Unregistered guest Posted From: 144.137.104.181 |

Hi All the Citroen DS used a centre takeoff rack but I know not if the seals are stationary. The Citroen CX has a more conventional rack as far as steering takeoff (ie power servo in the centre with steering rods attached to the ends). I am pretty sure the seals on this are staionary. I recently had a rack for my CX overhauled by Pleadies in Gayndah and I am sure they do RR racks as well. The job was done very well including the obligitory resurfacing of the piston. The CX rack has some seals of Rilsan plastic and this may be worth investigating as it is a material that seems tough with many uses. My hot water system is lined with the stuff, still going strong after 20 years. The other point to note is the pressures involved in the Citroen racks. In the DS full hydraulic system pressure is applied - 175bar although the CX has only half that at the rack. They don't leak generally either. Pleades often suggest improved sealing material on some of the Citroen work, maybe they have some knowledge and something to offer for the Shadow 2 rack (Message approved by david_gore) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 501 Registered: 4-2003 |

For Brad Clinch, Atlantic Enterprises in the USA offer a lifetime guarantee on their racks. If you want a repair kit, try them. If there is a next time for me, I shall enquire there too as they are so confident in their quality. A kit usually costs half the price of an exchange rack. There is surely no difference betweek a LHD and RHD seal kit. http://www.atlantic-ent.com/ Bill C. has also had excellent service from Penshurst Steering in Sydney, and I'm sure that Robert Chapman Automotive offers options too. RT. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 502 Registered: 4-2003 |

Let me float an idea in a completely different direction here. It may be clutching at straws, but it's worth eliminating or otherwise, as the police say with DNA tests. In the return path, the steering fluid passes through the anti-joggle valve screwed into the spool valve assembly. This valve ensures a residual pressure in the rack at all times while driving. Could a change in the pressure setting of this valve improve seal life ? I could imagine that an increase, or indeed a decrease, may have some effect, useful or otherwise. The conflicting rationales: An increase in backpressure would load the seals up to seal better. A decrease in backpressure would reduce seal load and thus wear rates, and also reduce "blowout" and fluid forced continuously past the seals. Any ideas ? Maybe faulty anti-joggle valves are the hidden cause after all, and we have been blindly changing racks and putting them back with faulty valves (even though mine check out OK) ?? By the way, for Larry H: Atlantic only do LHD exchange racks. The sole difference between an R-R rack and its Bentley equivalent is limited to the stiffness of the torsion rod in the spool valve assembly, giving the Bentley less assistance and greater feel. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 172 Registered: 9-2004 |

Richard great thoughts i will digest them and see what the old brain comes up with. I have another thought as well,is there anyway the rack could be stressed and distorted on the mountings or in use or otherwise on some cars and not on others? Is it both gaitors that leak madly. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 504 Registered: 4-2003 |

Pat, Gaitors do not leak unless split. Gaitors are to hold out dust and to hold in the rack oil (early type) or grease (later type), not to be confused with the DEXRON III or Transmax Z power steering fluid. They share the same gear cavity and are at atmospheric pressure at all times. One issue is that when fluid gets into the gear cavity, it washes away the oil or grease causing wear to make matters worse, and eventually squirts out throgh the vent. The rack gear cavity breathes through the steering link-to-rack bracket mounting bolt holes: they are an intentionally open fit in the moving rack piece, and are secured to the rack gear block itself well inside the cavity. The bracket bolted to the rack is so shaped that any pressure build up or vacuum inside vents past those securing bolts to a tiny shaped cavity in the bracket interface and vents at atmospheric pressure. Venting is necessary: different temperatures and altitudes, let alone fluid leaks, need somewhere to vent without bursting the gaitors. This is the bracket I mean. On the other side it is shaped to provide the ventilation to the gear cavity.  | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 505 Registered: 4-2003 |

The silvery-coloured thingo, seen here between the second-lowest pipe and the spool valve assembly, and looking like an adaptor union, is the anti-joggle valve. PS: The gaitors are certainly not intended to keep power steering fluid inside them, and should never come in contact with steering fluid on a serviceable rack.  | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 173 Registered: 9-2004 |

Hum, a trip to the attic. Seem to think the gaitors do leak when the seal is lost to fluid and pressure build up in gaitors, results in leaks round the gaitor joint of the clips. Some gaitors have return vents to the reservoir to return the wasted fluid that is used as lubricant. However as you state the fluid is expelled through the block bolts so there should be no fluid there in the first place. How about the mounting distortion etc? | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 506 Registered: 4-2003 |

Maybe Metalastic mounts for the rack on one side rather than rigid would relieve all stresses ??? Perhaps I'll fit a strain gauge under the left hand rack mount one time and chart the stresses with a data logger. If the subframe itself flexes, there may just be some answers revealed. However, this would not really explain why very new or rebuilt racks can fail under very mild conditions. RT. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 174 Registered: 9-2004 |

Richard back from the attic,this is where the centre take off power rack started, running at 2500lbs very few probs unless wrong fluid was used this was the year 1962.CITROEN. Note the seals are stationery as Robert stated on the Jag type. I will read up and see if there is any mention of seal material. Citroen had imboard brakes which helped to cut out the disc runnout ie another cause of rack faults, dynamic imbalance!  | ||

Brad Clinch Experienced User Username: brad_clinch Post Number: 8 Registered: 11-2004 |

Hi Richard, Thanks for the tip. As I’m down-under, I considered I’d try Penshurst first. Though the ‘lifetime guarantee’ from Atlantic Enterprises does sound attractive. Had I a spare rack, I’d probably have sent it to them for O/H, which should alleviate the non-RHS exchange obstacle. I was also advised as per your other suggestion to try Penshurst Steering by ‘Bentley, Sydney’. David at Penshurst Steering has quoted AU$693 including GST to overhaul my rack (assuming there are no unusual major problems with it) and gives a 2 year warranty. He said he can generally give a turn-around service of a 2 day maximum. Upon asking him about the seals he uses, he stated that he uses ‘up-graded’ seals on the shaft and 'fresh' seals from the UK in the remainder. ‘Fresh seals’ he said is the ‘secret’ to a lasting result. He added (if I understood correctly) that there have been (about 4) upgrades to the rack / seal design since my 1979 model rack. So yesterday I removed my rack and thoroughly packaged it for sending to them. David is also going to supply an in-line filter for the return line at AU$22-. They should receive it Friday, and he’s said he’ll start on it straight away. Will let you know how it goes. Additionally, the number and depth of comments on this subject I have found most interesting. Thanks to all. I certainly agree with Robert Chapman’s opinion; that it is (far) preferable to have seals fitted stationery inside a cylinder / tube and have a PTFE collar type bearing fitted to the end of the shaft, rather than the seal fitted to the shaft and sealing against the tube. Aircraft nose oleos and main gear struts and also motorcycle front struts use the same logic. Yet the centre take-off design of the RR system probably tends to inhibit this more sound an engineering practice in this particular instance. Regards, Brad C | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 521 Registered: 4-2003 |

Brad. Clearly, the mobile seals are the price we pay for a simply-realised centre-link takeoff. Stationary seals, shaft-to-housing, are far superior and simpler. That arrangement, with an external cross-link between the two output shafts to provide a centre-takeoff without all the seal and flexing dramas is surely best. Good Luck. My New Rack is still dry after almost a whopping three months. RT. | ||

John Dare Prolific User Username: jgdare Post Number: 55 Registered: 12-2004 |

Thank you Richard. To the relief of many, you appear to have confirmed the long suspected FUNDAMENTAL cause of chronic rack reakage in R-R/Bs. The reasonable conclusion, being based upon the BALANCE of probabilities has (after many posts) now been delivered, albeit via a somewhat "wobbly" route. | ||

Brad Clinch Experienced User Username: brad_clinch Post Number: 9 Registered: 11-2004 |

Yes Richard, that would be about the only way around it and still possibly be able to maintain about the same overall width of the assembly. My O/H ed rack arrived yesterday... for fitting this weekend. Will advise how it goes. Brad C | ||

Brad Clinch Frequent User Username: brad_clinch Post Number: 12 Registered: 11-2004 |

Hi all, Thought I'd let everyone know; I re-fitted my steering rack overhauled by David at Penshurst Steering on Sunday 16th January. It is still fine, and has a 2-year warranty should I have any problems. And I also fitted a filter in the return line. Regards, Brad C | ||

Brad Clinch Unregistered guest Posted From: 27.0.69.169 |

I was just perusing this forum, and came across this old string from 2004/2005. As an update, I'd like to comment that with now 150,000+ miles, the steering rack overhauled by Penshurst Steering in Jan 2005 (when 62,000 miles on it), is still perfect. I've replaced the filter twice since, but have had zero problems with the rack since overhaul. Testimony to a superb reco job! (Message approved by david_gore) |