| Author | Message | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 406 Registered: 5-2013 |

Hi Folks, I replaced a trunnion boot and observed that there was no source of gear oil, so I concluded that the gear oil in the differential stayed in the differential and did not migrate into the trunning housings. I further remember, possibly erroneously, comments about ports for adding oil to the housings, which would have made sense but I've looked without success. How do I supply gear oil to the trunnions? Thanks for the help, Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1936 Registered: 6-2009 |

Chris, You are indeed correct that the differential/final drive oil stays there. In fact, the trunnion/Detroit joint oil tends to slowly seep into the differential. It is not unusual to find the differential full to above the fill plug if the trunnion joints have been kept correctly lubricated and the differential oil has not been changed in some years. On each Detroit joint, where it hugs the differential, there is a small bolt on one side of the oval shaped metal housing. You remove this to add oil to the trunnion joint. These should be checked yearly in an ideal world. I have found repurposed hair dye bottles to be the ideal size to fill about 2/3 full and get into the tight space you have to work with when the fill port is pointed almost upward.  Brian | ||

Omar M. Shams Grand Master Username: omar Post Number: 672 Registered: 4-2009 |

Thanks for the tip Brian. And thanks for jogging my memory to check my Detroit joint /trunion oil level Chris. Omar | ||

Patrick Ryan Prolific User Username: patrick_r Post Number: 238 Registered: 4-2016 |

Great stuff Brian, Is there also a corresponding level hole? Or do they get filled to the top? Lastly is the oil used a typical 90 grade diff/gear oil? | ||

David Gore Moderator Username: david_gore Post Number: 2064 Registered: 4-2003 |

Patrick, The trick is to position the drain plug at the clock position for either 4 or 8 o'clock and squirt the oil in using a suitable squeeze bottle with spout attached to a clear PVC tube until oil starts to run out of the plug hole - any more is going to flow straight into the differential housing past the bearings. From memory, the specified refill volume for each trunnion is 150ml. I used Castrol SAE90 EP oil for both the differential and detroit trunnion. | ||

Patrick Ryan Prolific User Username: patrick_r Post Number: 239 Registered: 4-2016 |

That's a great tip David. I will be under the car this weekend. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1270 Registered: 5-2012 |

Another great tip that Brian always gives on the related procedure of changing the diff oil is to always loosen the filler plug before removing the drain plug. This is because it is possible that having drained the oil you then find the filler plug is corroded in and cannot be removed. Of course, the filler plug will have to be removed, but checking it first means the much longer job of freeing it off, with the possible removal of the rear cover and ordering of a replacement gasket, can be scheduled in better. Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 407 Registered: 5-2013 |

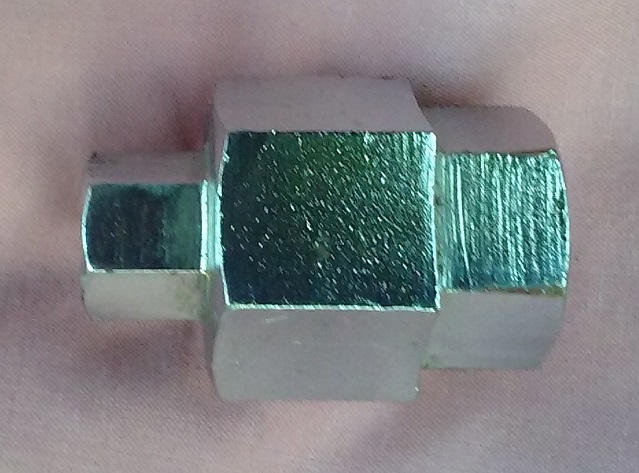

On the topic of removing the filler plug, I didn't have a half-inch Allen wrench, so I used a coupling nut and a socket wrench. The coupling nuts came in a pack of three from Home Depot for $1.40. It turns out that a 5/16" threaded rod needs a coupling nut that is manipulated with a 1/2" wrench, and that fits the plugs in the differential.  I use the same trick for opening the Accumulator Control Valve. Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1938 Registered: 6-2009 |

Chris, Are you sure about that ACV comment? The ACV plug is a 1" hex and I do not think that even the large side of the Britool that comes with the car for the oil sump plug, differential plugs, etc., is anywhere near that and, if memory serves, the depth of the recess on the ACV will not allow the fattest part at the center of the Britool to drop in.  I always put in about 6 fluid ozs/175 ml of HP gear oil in to each trunnion joint with the fill hole positioned at the 2 or 10 o'clock position. Of course, if I hit "overflow" before that much fits in I stop. Brian | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 408 Registered: 5-2013 |

Hi Brian, Well, there are two parts to this answer, because I was unclear in my statement. Yes. I use a coupling nut to open the AVC. No. It is not the same one I use to open the fill plug on the differential. (I haven't tried to open the drain plug, yet, as per suggestions previously offered, so it may even be a third size, but in my case, I have Allen wrenches up to but not including 1/2") Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1272 Registered: 5-2012 |

Here are my efforts:  The one on the left is for the drain plugs. On my car it fits the engine and diff plugs. It is a 14mm hex socket carefully filed down to 13.6mm across flats. It fits perfectly. If you put enough force on it, it would rip the sump off before rounding the flats. The other is a 1" AF coupling nut that I bought from a local fastener specialist. Their minimum order was $5, a bargain at the price. Geoff | ||

ross kowalski Grand Master Username: cdfpw Post Number: 382 Registered: 11-2015 |

Just refilled my trunions this evening. Went to the dollar store and bought this.  Located the correct gear oil (because I have five gallons)  Rotated the trunion fill ports down to drain.  Relocated the ports up and refilled using the syringe. It looks awkward because I was trying to take a picture, in truth it was cake.  The syringe was 30ml so 5 syringes full and Bob's your uncle. I didn't even get any gear oil on the ground. | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1456 Registered: 4-2016 |

Nice work Ross. A good thread that's for sure. | ||

John Beech Grand Master Username: jbeech Post Number: 338 Registered: 10-2016 |

A possible alternative to the syringe (or the beauty salon bottle, which Brian recommended) is a wash bottle. Graingers have them (or any laboratory supply). Wash bottle: http://tinyurl.com/n4ebqzv | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 1389 Registered: 5-2015 |

I use a westcot squirty oil can wif 90 oil diff oil. I put the filler hole at 12 o'clock squirt one can in then turn filler to 3 or 9 o'clock to allow excess to dribble out. 6 o'clock to drain oil. One cup of tea job. why oil and not grease anybody know? | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1270 Registered: 9-2004 |

Bob, grease at speed it will settle in the wrong part of the rubber boot this can cause an imbalance at speed and not lubricate the required parts. Centrifugal force at play. | ||

Patrick Francis Frequent User Username: jackpot Post Number: 86 Registered: 11-2016 |

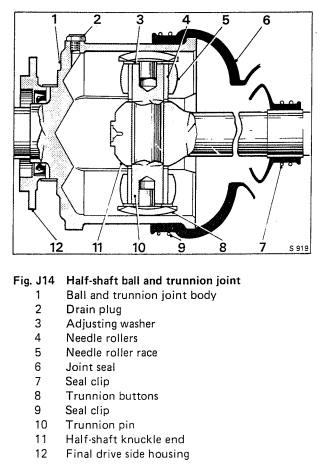

Hi Guys I am copying and pasting a document that I have on my computer. (probably written by one of our beloved Gurus on this forum!) Hope it is useful: A SOURCE OF VIBRATION The poor old rear axles one of which is pictured here are often quite neglected. They should have grease nipples in the universal joints (Item 3 in the drawing) and a filler plug (17) for the trunnion joints on the inner end. Removal is very simple involving undoing the two saddles and the half dozen nuts securing the inner bearing flange (37) to the rear axle casing. The inner trunnion joint was as you know copied from Buick immediately after the last World War. The joint was used on the front end of the propeller shaft on all the Silver Clouds and Phantoms V and VI and also the very early Shadows. They are very expensive to produce are fiddley to service and the rubber sealing boots are very difficult to replace. They were discontinued on the propeller shaft shortly after the start of Shadow production but continued to be used on rear axles until the Spirit line got established. As with any other joint they wear and vibrate and on a Shadow this is often felt on acceleration. One quick cure is to reverse the axles which are identical. While doing so have a very good look at the boots ((7) to ensure they are not about to puncture and consider replacing the universal joints. They are not expensive and can be the cause of a pronounced ‘clunk’ when engine power is applied. And seeing that you have the axles out why not pull out the inner bearings (38) and replace the oil seals (35)? TRUNNION MAINTENANCE When did you last have a look at these dear old things stuck either side of your differential (read final drive). They have quite a job to do are very expensive to replace yet the number I find utterly empty of oil. If you haven’t been there get the car up into the air clean around the filler plug and remove it preferably when the plug is at 3.00 o’clock. Ideally oil should just start to dribble out. If not turn the trunnion down until it does dribble which will give you an idea of how much is there. You may as well let the lot out and start again. The required oil is the same as that you put in the diff of 90 viscosity and the quantity is 150 millilitres. That is about ˝ a coffee mug, the amount is not really critical. The easiest way I find to get it in is to use a medical syringe available from most chemists. The most common size available is 50ml. Buy three, fill them all and take them under the car with you. Pull the plunger out fill it with oil pop the plunger back poke it in the hole and squeeze. The more clever among you will 663 also realise that the trunnion has the right amount of oil when it is just about to overflow when it is horizontal. While you are at it of course have a very good look at the rubber boot which keeps the oil in the assembly any splits or holes and the boot has to be replaced. | ||

Patrick Francis Frequent User Username: jackpot Post Number: 87 Registered: 11-2016 |

interesting suggestion to swap half shafts over to even out wear and tear. I did that. | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 1399 Registered: 5-2015 |

Grease or oil. Imbalance is a good answer also it's easier to get oil in. the exhaust heats the lefthand drive boot up. | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1477 Registered: 4-2016 |

My 1925 Chev has a type of trunion/CV joint directly out the back of the transmission, that leads into a torque tube. It requires "train oil" not sure what that is, plus it has an Alemite grease nippple, so I just pump grease into it. | ||

David Gore Moderator Username: david_gore Post Number: 2536 Registered: 4-2003 |

Patrick, "Train oil" aka "steam oil" was a very viscous oil for maintaining lubrication of moving parts on steam engines - if my memory is correct, it was also specified for lubricating items on pre-WW2 cars: http://www.penriteoil.com.au/products.php?id_categ=13&id_products=661 * | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 1400 Registered: 5-2015 |

modern cv graphite runny grease might be better. depends on oil tightness |