| Author | Message | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 71 Registered: 6-2009 |

Now that my car (SRH 37431) is on the road again, I can finally continue to tackle some of its previous problems. The car always suffered from vibrations through the steering wheel and seats, starting at around 40MPH. The rear ride height is spot on and level. Over the last 2 years I did the following : - 4 new tyres, balanced on the car - replacement of 2 "suspect" steel wheels - 2 new front brake discs (they were past their best) - swapping the halfshafts and replacing the UJ's (this improved matters somewhat) - Replacement of the front engine mount Over the last few weeks I replaced the propshaft UJ's and had it balanced. I also replaced the torque arm mounts (they were in a poor state). On a recent test drive it now seems I made things worse : it now starts vibrating strongly through the steering wheel at 20MPH, at 30MPH it gets better and at 40MPH it's just as before, vibrating through steering wheel and seats. At 40MPH I coasted to a halt with the gearbox in neutral and the vibration (especially through the steering) was just as bad. I can only think of 2 things to do next, but before I do them (and maybe make it worse again) I'd like to get your advice : 1) change the rear crossmember mounts 2) I recently adjusted the rear engine mounts (droppped the engine somewhat)because the propshaft was touching the underside of the car when accelerating. Now that I changed the torque arm mounts I might have to adjust them again. Any advice is welcome. Benoit | ||

Brian Vogel Grand Master Username: guyslp Post Number: 419 Registered: 6-2009 |

Benoit, The only advice I can offer at this juncture is that if you decide that several things need to be adjusted, only adjust one at a time. At the very least this allows you to know whether that thing has had any effect before starting with the next variable. These kinds of problems are maddening, but even if 15 things need to be legitimately fixed still fix each singly, see what effect that single modification has made to the problem, then proceed to the next. (Deciding the order is a different kettle of fish.) Brian | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 72 Registered: 6-2009 |

Brian, I appreciate your comments and I probably wasn't very clear, but all these repairs were done one by one over a 2 year period. Only replacing the driveshaft UJ's improved things somewhat. I did rebuild the propshaft and replaced the torque arm mounts at the same time, but only because, with the propshaft removed, it's much easier to reach the necessary torque arm mounts bolts. My problem at the moment is that since this last repair I now have that strong steering wheel vibration between 20-30MPH and I can't figure out how that happened. Benoit | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 75 Registered: 3-2012 |

Hi Benoit, how about taking the car to a garage/test center with a rolling road to establish whether its a mechanical driven vibration ie engine gearbox drive shaft etc , or might it be a front end problem ie steering. The rolling road can also be used on front wheels to isolate the problem to the front with engine off etc?. hk | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1040 Registered: 6-2006 |

Hi Benoit, When you say you have a vibration through the steering wheel - Is it a vibration at road wheel speed? Is the steering wheel moving left and right a bit, is the frequency changing with roadspeed ? Does ir get better or worse after driving for a while? Tyre pressures Ok? Did the paint-shop have it sitting for ages or have a heated spray booth. Re-balance wheels. Does it die away at 40 mph and come back again at say 56? or Is it a vibration which is faster like using an electric drill etc? vibrating your hands? Is the front engine mount stop adjusted with a sufficient gap? | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 73 Registered: 6-2009 |

Paul, at between 20-30MpH it is a strong vibration, with the wheel moving left and right. Between 30-45MPH there is almost no vibration at all. From 45MPH it is a different vibration, as you feel it through the seats, steering wheel and pedals. It increases gradually till 70MPH and then it stays pretty much constant. It's really 2 different sort of vibrations that seem unrelated. I have a theory for the first "vibration" : over the last month I removed and reinstalled the propshaft, wirebrushed and undersealed part of the floorpan and mounted new torque arm mounts. For this the car has been standing a lot with the rear jacked up, putting a lot of weight on the front wheels. Could it be that the tyres have developped flat spots ? It really feels like an out of balance tyre, but it happens at too low a speed. The front engine mount has sufficient gap. Regards, Benoit | ||

Jeff Young Prolific User Username: jeyjey Post Number: 161 Registered: 10-2010 |

Low-speed vibration: flat-spotted tyres? High-speed vibration: detroit joints? (Only guessing.) Cheers, Jeff. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 74 Registered: 6-2009 |

Jeff, yo're probably right in suggesting two different causes. I'll check for flat spots and if so, maybe I can drive them out (but not a certainty). All UJ have been replaced, so I'll have to look further and might replace the rear crossmember mounts (they're probably just as bad as the torque arm mounts were). Benoit | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 75 Registered: 6-2009 |

I took the car out for a short test drive (+/- 25 miles) and the low speed vibration has improved somewhat, strengthening my belief the tyres have a flat spot. Maybe after driving it some more they will become round again. As for the vibration from 45mph +, it gets stronger when accelerating, braking and turning (left and right) and on some road surfaces. I jacked up the rear of the car (under the diff) and can clearly see the crossmember moving upwards (almost against the floorpan). Am I correct in assuming this means the mounts are perished, allowing the crossmember to move (which would explain why the vibration is even worse with changes in speed or direction) ? The bootfloor has been strengthend around the crossmember mounting points, so at least I know that can't be the problem. Benoit | ||

Geoff Wootton Prolific User Username: dounraey Post Number: 203 Registered: 5-2012 |

Hi Benoit When I bought my car, SRX18501 about a year ago I was getting very generalised vibration that improved after about 10 miles or so. The car was fitted with what appeared to be a good set of Hudson Signature whitewall tyres. There was plenty of tread and they looked good. However, due to the vibration I suspected the tyres and checked the age from the numeric code on the side - it was 6, denoting the 6th year of the decade. 2006 I thought, until I read that Hudson went out of business in 2001, making the year of manufacture 1996. Or could it have been 1986!!! - 26 year old tyres !!!! Needless to say I replaced them and the vibration completely disappeared. I know that your tyres are much more recent than that, however a flat spot on one or more of them is a distinct possibility. The fact that the vibration on your car gets less after 20 miles or so is a classic symptom of flat spots. After a few miles of driving the tyre heats up, becomes softer and the vibration gets less. Usually, when the tyres have cooled down the flat spot reappears. Certainly worth leaving it for a while to see if the tyre vibration does go away before changing the tyre/tyres. Geoff | ||

Kevin Lagden Frequent User Username: kevin Post Number: 83 Registered: 7-2009 |

I agree Geoff, I recently changed my tyres to Mastercraft white walls as the one's on SRH19305 were over 6 years old. Soon as I did the road noise improved dramatically and a slight vibration went altogether. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 76 Registered: 6-2009 |

Hi Geoff, the tyres were the first thing I changed as the car was still running on very old Avons. New Continentals improved road noise and road holding, but the 45MPH+ vibration stayed the same. Even after the tyres have warmed up considerably, the vibration is constant. However, the recent low speed vibration is indeed probably due to a flat spot on one of the tyres. Benoit | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 77 Registered: 6-2009 |

Investigating matters further a new problem reared its ugly head.  Although the car sits level I decided to check the height levelling anyway. To my surprise the RH height levelling valve was adjusted to be as low as possible and the LH valve was the opposite, with the control arm pushed upwards. When I disconnected the control arms and operated them manually, only the RH one worked. The LH one felt normal (as in sufficient giving in enough resistance when pushing/pulling the operating arm) but nothing happened. I guess the valve is at fault or could it be something else ? Could the fact that on one side the height levelling valve doesn't work cause vibrations through the car ? On a positive note though (and I can use some good news) : my rear springs must be in good shape as the car is level with a correct ride height. Benoit | ||

Brian Vogel Grand Master Username: guyslp Post Number: 423 Registered: 6-2009 |

Benoit, Since the height control system is never supposed to be actively adjusting things unless the car is laden in the rear seat and/or boot, it is highly doubtful that this is contributing to your vibration problem. If the car is sitting at the correct ride height with the springs alone when it's unladen, and it should, and you're the only thing in it when doing your test drives I'd not suspect this is your issue. That being said, it's worth looking at the material I posted long ago on this thread on rollsroyceforums.com to see if your vibration issue might seem to match some of the hydraulics issues that cause same. Doubtful, but possible. Brian | ||

Geoff Wootton Prolific User Username: dounraey Post Number: 204 Registered: 5-2012 |

Hi Benoit I seem to recall in a previous entry that you had recently replaced all the tyres, so it's unlikely to be the cause, even though some of the symptoms of the low speed vibration point to this. However, it is worth checking the age of the your new tyres, just in case they had been lying around in the warehouse for a few years; highly unlikely I know but worth checking. RT put up an excellent article on checking tyre age a while ago: http://au.rrforums.net/forum/messages/30/TyreAge-8116.pdf Regards the low speed vibration through the steering wheel, I would re-assess the steering joints and front suspension for any worn parts again. Also check the tracking, particularly as you have replaced the front brake discs. I find the string method quite accurate enough for this assessment. Geoff. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 78 Registered: 6-2009 |

Hi Geoff, my tyres have the Dot code 0908, so I guess it means they were manufactered in the 9th week of 2008. As for tracking, I always thought a car out of alignement wouldn't be a cause for vibration, but rather noise, premature wear or pulling to the right/left. But I could be wrong and will check it. In the meantime I've ordered the rear crossmember mounts. When I jack up the car under the diff, the crossmember moves upwards quit a bit and it almost touches the floorpan. We'll see if that helps. Also, I've followed Hubert's advice and in a few weeks time I'll be able to put the car on a rolling road to see if we can isolate the problem. | ||

richard george yeaman Frequent User Username: richyrich Post Number: 89 Registered: 4-2012 |

Hi Benoit. You might try swapping your front wheels to the rear, just a thought! Cheers Richard. | ||

bobuk Unregistered guest Posted From: 94.197.127.23 |

Check inner joints on rear drive shaft must have oil at correct level. NOT GREASE Always remember RR is not like an Aston Martin where they used customers to road test the cars. RR thrashed Shadows across desserts to see what goes bang so don't imagine that RR would design a car where drive shafty angles can cause vibs. Many years ago a man I worked for needed cement real fast so he went to the cement shop and loaded his 6 month old Shadow 1 with as many bags as they could stuff in it and drove 70 mph down the M4 for nearly 30 miles. No problems. Then a Shadow was about £20k new and the job we was working on was worth over a million quid. At the time he would by a Rolls-Royce and order the next one. Then when the new one turned up he would sell the first at a profit and repeat the game. HR Owens of London must have known what he was doing because they were servicing the cars for the new owners. Mega rich people for you. (Message approved by david_gore) | ||

Brian Vogel Grand Master Username: guyslp Post Number: 430 Registered: 6-2009 |

Well, now that bobuk mentions it, vibration issues can definitely be caused by wear in the Detroit/trunnion joints. I've heard enough horror stories about these poor joints not having their EP gear oil levels checked for decades. They will slowly leak oil into the final drive/differential and there's no way to know if/when they've gone empty. Checking them once a year should be on the "routine maintenance list." The good news is that you can switch them out from one side to the other and get new wear surfaces, at least if it's not been done before. It's also common to replace them with the later Lobro joints used on the SZ series cars. After all this information, however, my experience and the stories shared with me tend toward the vibration only coming on at highway speed and often being present only above a certain minimum speed and below the "fade out" speed somewhere above the minimum. Brian, who begs to differ on the "RR never used customers as testers" based on the progression through multiple hydraulic fluids and many pump failures before the advent of RR363 | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 79 Registered: 6-2009 |

I check the oil level in the trunnions every 6 months, but of course a previous owner might not have done it. I already swapped over the halfshafts, but with no result. I know about the Lobro joints, but as it quite expensive, I'd rather not go down that route. Let's see what new rear crossmember mounts will do. Benoit | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1041 Registered: 6-2006 |

hi Benoit, worn trunnion joints give a vibration like feeling when under load. When free wheeling the balls are not pressing against the worn part so the vibration goes. Also the harder you accelerate the worse the feeling. if you jack the rear up and put it securely on stands them chock the front wheels, you should be able to drive the rear wheels through the speed range and feel for the vibration. you May be able to narrow it down front or rear that way. swap wheels front to rear and repeat. Hold a large wax crayon close to spinning items and move it minutely towards the part and see if it marks one side and not the othercan indicate a run out which can cause vibrations. Tyres and wheel rims especially . if a vibration gets worse at say 25 mph then dies off as you go faster and then gets worse again at 50 mph them dies off again until 100 mph it is definitely a balance issue. Harmonic resonance causes that phenomenon . Unfortunately I can't remember getting a steering wheel judder from even the worse diff carrier mounts. the carrier is hanging from the mounts so jacking the diff relieves the weight and raises it before raising the car. I almost had to go to Belgium to collect a Bentley and was going to call you. I would love to drive it and feel it for myself. good luck. Paul. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 80 Registered: 6-2009 |

Hi Paul, thanks for all your help. From what you describe it looks as if worn trunnion joints could well be the cause of the vibrations, even after I swapped them over. Flying Spares only sells complete used driveshaft assemblies, which I guess, not being new, might also suffer from wear. Is there a source for new or reconditioned trunnion joints ? Regards, Benoit | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1045 Registered: 6-2006 |

Hi Benoit, Is your vibration only under load? Are there any long hills near you where you can got up to the right speed then put it in neutral! If it goes when free wheeling then it may be them. Are the outer UJs ok? I've seen people fit New ones and a roller has fallen inside on assembly causing a tight spot which they thought would settle down. I will have good used trunnions here I can supply you. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 82 Registered: 6-2009 |

Hi Paul, the vibration starts at +/- 45mph : it's constant, but much more noticeable when accelerating, decelerating and turning. When driving at a constant speed it's better, but still noticeable. I really feel it through the seat and pedals. The steering wheel also vibrates, but not in a "sawing" motion as with unbalanced wheels. Unfortunately, Belgium is a mainly a flat country, so no long hills where I live, I'm afraid. In a few weeks time I'll have it on a rolling road, which I hope will at least clarify if it comes from the front or back of the vehicle. The outer UJ's are OK, altough fitting new ones only helped a bit. I am defintely interested in the used trunnions if they turn out to be the cause. Regards, Benoit | ||

arthur hawley Unregistered guest Posted From: 112.213.154.164 |

check where the steering column is attached to under the dashboard, also the base of steering column at steering box, vibration may be in loosely attached column (Message approved by david_gore) | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 83 Registered: 6-2009 |

Instead of a hill I found a bridge with a long downwards slope. At +/60mph I put the car in neutral and coasted to a halt. The vibration stayed the same and got a little worse when I braked at the end. So I guess this rules out the drivetrain. The front discs have already been replaced, so they can't be warped. Maybe the rear ones ? I already suspected that the low speed vibration was due to flat spotted front tyres and this seems to be the case. You can see the distance between the tyre and the piece of wood changing (+/- 2-3mm) http://www.youtube.com/watch?v=Rz8D9wPRiZ4 Driving though has aready improved matters. I stil have to check the rear tyres. All 4 tyres where changed a few years ago with no improvement whatsoever. Lying under the car I, with the car on axle stands and the left front wheel from the ground, I noticed something else. When I chucked the left wheel sideways without the front wheels turning, the centre part of the steering rack moved upwards/downwards. Is this normal ? http://www.youtube.com/watch?v=W1BH3Adt9es Benoit | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1051 Registered: 6-2006 |

Benoit, you can try having your wheels balanced again. This may help the higher speed wobbles. Out of shape tyres will always give a movement at slow speeds though. The rack should not move at all really. Some people say that they can tell when it's worn, others say it makes no difference. Yours is at the worse end of the scale though I'm afraid.  Perhaps with the tyre and the rack combined??? | ||

Jonas TRACHSEL Experienced User Username: jonas_trachsel Post Number: 35 Registered: 2-2005 |

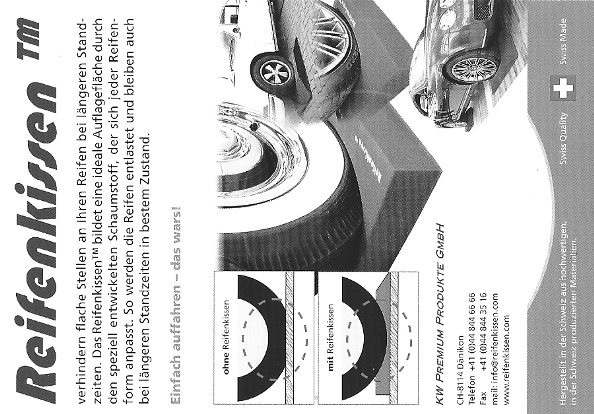

Re flat spots on tyres: I will try to add an advertisement we regularly get in our Swiss RREC-Magazine, the "Alpine Eagle". Sorry, had to turn it sideways..... Jonas  | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 84 Registered: 6-2009 |

Hi Jonas, that looks interesting as my car isn't used very much during the winter. But as all 4 tyres have a lot of run out and I haven't read a lot of good reviews on the tyres themselves (Continental EcoContact) I wonder if they might have been defective from the start (they all have the same production date code). Over the next few weeks I'll have it on a rolling road and I have managed to borrow a different set of wheels, so hopefully that will give some more insight on the problem. | ||

David Lacey Experienced User Username: dlacey Post Number: 12 Registered: 11-2010 |

propshaft? | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 85 Registered: 6-2009 |

Hi David, I recently dismantled the propshaft, replaced the UJ's and had the whole assembly balanced, so that should rule it out. Regards, Benoit | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 86 Registered: 6-2009 |

I finally managed to borow a different set of wheels, but unfortunately this made no change whatsoever to the vibration problem. I then had the car inspected by the Belgian automobile club : they checked the suspension for wear on shaker plates, but there wasn't too much play. The car then went on their rolling road and the vibration was still present, so I am now certain it comes from the rear. On driving home, it was again clear, that the faster it goes, the harder it vibrates (becoming almost unbearable at 75mph). And also vibrating much harder under serious acceleration. As I've changed most things, I wonder if the driveshafts are to blame, being so worn that swapping them has had no effect. Benoit  | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 76 Registered: 3-2012 |

Benoit, I Know I mentioned this before but you might consider looking at the rear cross member and the centre point both brake cables are attached from here. On my Shadow had similar situation, faster I went the nose increased... reason being the brake cable came away from cross member, the cables then sat on the drive shaft and scraped away until I discovered it was not , brakes, drive shaft .. this diagnosis simple as it might seem took me weeks to locate. Any luck it might be the same problem. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1072 Registered: 6-2006 |

Benoit, usually if it worse under load it is not a balance issue. have you refilled your diff and half shafts ? regreased your ujs ? I should have some good used trunions you can try on a sale or return basis. After the accident, how was the car extracted from the garage and recovered? | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 87 Registered: 6-2009 |

Paul, when I bought the car I changed all the fluids : the oil that came out of the diff however looked real old. The half shafts where dry. In the meantime I changed the oil in the diff twice and regularly check the level in the half shafts. The UJ's have been changed and regreased. The car was recovered on a trailer, having been pushed only a few metres. Besides, the vibration was already present before the accident. Benoit | ||

Omar M. Shams Grand Master Username: omar Post Number: 341 Registered: 4-2009 |

when the car was recovered on the trailer....... where were the straps anchored to ensure the car is held on tight? | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 88 Registered: 6-2009 |

Hi Omar, the straps where secured through the slots in the wheels. However, as the vibration already occured before the accident and the car subsequently being trailered, it can not be the cause of the vibrations. Benoit | ||

Jeffrey McCarthy Grand Master Username: jefmac2003 Post Number: 422 Registered: 5-2007 |

Benoit - this might be a little 'left field' as we say in English when something is not obvious. Have you had occasion to change your seatbelts? The bolts holding the front stalks to the transmission tunnel are a specific length. If you accidentaslly use a bolt even slightly too long (like the ones on the B pillar) it will touch the transmission shaft and rub against it causing either vibration or noise or both. Just a thought because I once did this very thing. Jeff | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1080 Registered: 6-2006 |

Benoit, recovery - good - They are hard to recover ftom behing hand have seen damage from straps on drive shaots , diff carriers, & torque arms. Trunions on their way. I had another thought when I was digging through the parts. I wonder if at some point somebody has moved the pin - to fit a new rubber boot for instance - (don't do it that way people) and it has nor been centralised. It would be a good idea to check that when it's out. Cheers, Paul. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 91 Registered: 6-2009 |

While awaiting the replacement trunnions, I've been experimenting somewhat. I loosened the differential torque arm mounts a bit and took it for a short drive. This strongly increased the vibrations wich I guess confirms again that the cause must be somewhere in the back axle. Coincidentally, with new mounts installed the vibrations are slighly less noticeable. New differential carrier mounts didn't help the vibration problem but at least the slight differential whine on deceleration dissapeared completely  Benoit | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 92 Registered: 6-2009 |

I removed the RH halfshaft and it doesn't seem right : the shaft has been rubbing somewhere. I'm open to what could be the cause.  | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1084 Registered: 6-2006 |

Trying to picture it, could one of the bevel (belleville) washers have dropped when you put it back together last time? | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 93 Registered: 6-2009 |

Hi Paul, it might well be. Which way are the bevel washers supposed to be mounted ? With the deepdished side towards the diff or towards the halfshaft ? Benoit | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1085 Registered: 6-2006 |

small hole fits against the drive shaft, large diameter to the diff. there is room for one to fall inside the diff , so watch outfor one down therein | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 94 Registered: 6-2009 |

I've replaced the trunnions with a pair of good used ones but unfortunately to no avail. The vibrations are still there. So back to square one. Could bad rear wheel bearings cause so much vibration ? | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 856 Registered: 9-2004 |

A good start would imo be to use a dial gauge on all the wheel hub flanges if ok then do a static and dynamic wheelbalance on the car. A worn rack with no dampening will agravate the slightest imbalance. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 95 Registered: 6-2009 |

Hi Patrick, It's a good suggestion.. The steering rack is indeed very much past its best (enourmous play), so that could indeed "amplify" the vibrations. Benoit | ||

Randy Roberson Prolific User Username: wascator Post Number: 141 Registered: 5-2009 |

There is a machine made by Hunter in the US: the GSP 9700 Road Force Balancer, which will give the last word on wheel and tire problems. It loads the wheel-tire assembly against a steel roller and, if there are problems like a stiff or hard spot on the tire, runout in the wheel or tire, which can cause vibration, it will find it. Several years ago I had vibrations after buying a new set of higher-end Goodyear tires for my company car; repeated rebalance is all the Goodyear dealer could provide. Another local shop with the Hunter machine found the bad tire, and the Goodyear dealer promptly replaced it. Result: no more vibration. Interesting that I looked at the date code my Car's tires: made in the last week of 1989! 2013-1990= 23 years! Getting new Kumhos and having the wheels powdercoated now. My Car is not perfect but so far I have not found any vibration problems and I have been looking. On a new asphalt highway I got her up to about 70 and she was smooth as silk. Just keep looking, ther eis a reason and you will find it. | ||

Omar M. Shams Grand Master Username: omar Post Number: 343 Registered: 4-2009 |

Dear Benoit, The vibration is from the rear of the car. We have established that on the rolling road. Stay focused on the rear. I had the same issue with my SRX 36212 and never found out the root cause. Like you, I looked at everything, but in the end the car was bought by a gentleman from Norway and he took it as it was. In my case the casue may have been reversing the car on a high concrete manhole that hit the diff. Not too different from your cause of vibration - your car was fine till you had the impact with the wall. My point is that you need to look at the rear end. I never replaced my subframe mounts but in my heart I always felt that this would be the solution. Have you considered looking at the mountings on the rear subframe? Thnaks Omar | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 97 Registered: 6-2009 |

Hi Omar, my car always suffered from the vibration problem, even before the accident. But you,re probably right that I should focus on the back end, but I'm reaching the end of what I can replace. The subframe mounts look to be in reasonable condition. The only thing that improved matters somewhat was replacing the diff torque arm mounts. Benoit | ||

David Gore Moderator Username: david_gore Post Number: 1321 Registered: 4-2003 |

Hi Benoit, The clue to the cause of your problem may be given in your last post where you mention replacing the torque arm mounts resulted in a noticeable improvement. This suggests to me that you are experiencing excessive movement of the subframe relative to the body possibly resulting in induced harmonic vibration which exacerbates the problem. I agree with Omar that the problem is most likely associated with the subframe compliance mounts which, in the best tradition of Murphy's [Sod's] Law, are the most difficult difficult to replace. Replacing the mounts would also be a good preventative maintenance measure especially if they have not been replaced previously during your ownership. Inspection for corroded body mountings may also reveal loose attachment of the mounts between the subframe and body. | ||

Mark Herbstreit Prolific User Username: mark_herbstreit Post Number: 104 Registered: 5-2005 |

Hi Benoit. I am following with interest as my Shadow II has also always had an annoying vibration. When I first got the car fifteen years ago it was only noticeable at the top of the suspension stroke. ie. when cresting a hump in the road. It has always been as soft and smooth as a pillow while cruising but under enthusiastic acceleration even the slightest imperfection in the road surface would also transmit as a harsh thump through the car. At first I thought the springs were bottoming so these were replaced. This seemed to make the vibration worse, especially when cornering through a roundabout. I suspected that as the ride height was slightly higher than standard that the drive shafts were running at too great an angle. About a year ago I replaced the torque arm rubbers and the diff bearings which were in really bad shape considering oil is changed every two years etc. None of this has improved the situation, so today things have gotten serious! I recently noticed that the diff carrier appears to have made contact with the spare wheel carrier.  Out with the diff carrier and mounts are shot so I have replaced them.  The suspension cushions also look to have collapsed, so these will also be replaced.  Trunnions and drive shafts do not appear to have any wear to my eye but I will swap shafts left to right as it seems to be the done thing.  The tail shaft uni also feels a bit stiff which is also surprising given the attention it has received over the years. This will be removed and investigated further.  In for a penny I will most likely have the delaney mounts overhauled as well. If none of this works I guess I will meet Benoit at the top of the tallest bridge between my place and his! | ||

richard george yeaman Prolific User Username: richyrich Post Number: 104 Registered: 4-2012 |

Hi Mark very interesting project Photos are very good also, Interesting to hear what the outcome is. Richard. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 98 Registered: 6-2009 |

Hi Mark, This is very interesting. Maybe together we can solve this annoying problem. I might replace the diff bearings like you did, altough at first sight they seem OK. I'm unsure about the suspension cushions. How to tell what their condition is and could they cause the vibration ? Have you tried loosening the diff mounts a bit ? I experimented with this and this caused the vibrations to seriously increase. I guess this means that the whole back end must be moving Replacing the diff carrier mounts didn't improve things for me either. Regards, Benoit | ||

Randy Roberson Prolific User Username: wascator Post Number: 143 Registered: 5-2009 |

In reviewing this entire topic, serveral issues come to mind: Shaking of the steering wheel and seats is usually of a much lower frequency (as that of a tire rolling, say, 400 to 800 RPM at highway speeds)and is usually caused by bad tires or wheels. A bad shock dampener can allow a tire-wheel with not all that much out-of-balance, to shake badly, because the normal dampening of the shock is enough to handle it, but it is missing. In soft-riding cars, the dampening rate is usually lower anyway, plus the tire air pressure may be lower, and these will affect the behavior. Vibration of a propellor shaft which is out of balance will be of much higher frequency, because at highway speeds the drive shaft turns the same speed as the engine, circa 2000 RPM, and the axle shaft would be turning slower than the drive shaft by a factor of the axle ratio; i.e. less than half. In the case of a propellor (drive) shaft, a strong humming should be very obvious in the floor. The perceived intensity of any vibration which is caused by out-of-balance conditions is related to the mass of the object, the ratio of the mass to the amount it is out of balance, the speed, and the resonant frequencies of the supporting structure. Usually a relatively small part is not likely to be the cause of a large vibration, like shaking the seats, but this has exceptions. Smaller parts at higher speeds often present as more of a noise than a vibration or shaking. Some cars with steering dampers will develop a sudden, violent oscillation-shaking in the front steering mechanism if the damper is not working correctly. Some can develop this if there are loose-worn parts. In short: vibration like steering wheel shake, seat shake, which is constant and varies with speed: look for tire and wheel problems. Higher frequency vibrations which vary with speed: look at the propellor shaft, including universal joints and support bearings. Sometimes u-jointed axle shafts which vibrate due to wear in the joints, will vibrate like an out-of-balance tire, either when pulling, pushing (i.e. engine braking) or coasting, and may change or go away when the load condition transitions. Loose suspension arm mounts or bushings: look for clunking on steering, braking, or bumps, or when the side loading changes, as in an ess-turn transition. Seems it would be rare for a loose suspension mounting part to cause a steady, repetitive vibration, unless it were binding a u-joint or similar moving part, or were being excited by a out-of-balance tire. I hope this helps. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 99 Registered: 6-2009 |

I got under the car again to check out the suspension cushions and Delaney mounts when I noticed something odd. The RH rear levelling valve adjusting rod was at its lowest point, while at the LH side it was at its highest. Investigating further it seems the LH levelling valve doesn't work at all. The RH valve works fine as I replaced it when I bought the car. The car sits level, but could the fact that one valve works and the other doesn't be the cause of vibrations ? | ||

Randy Roberson Prolific User Username: wascator Post Number: 145 Registered: 5-2009 |

Thoughts from a complete RR amateur but an engineer with heavy mechanical experience: there are two levelling valves, so each side acts independently of the other. Say your aunt sits on one side: that side would tend to sit lower, so that side would activate more than the other side, to return the car to level, although they may both activate somewhat, as they share the car structure in common. If there is no fairly substantial uneven load in the rear of your Car, it is likely you would not notice the car not being evenly level just because one side was not working. My opinion: it is not likely this is the cause of your vibration. With a heavy uneven load, maybe, but I doubt it even then, unless something else is not right. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 568 Registered: 6-2009 |

Benoit, Your height control valve discovery is not likely to be linked to your issue. The height control in the car should not even be activated if it's only you driving or you and a front seat passenger. You need to have a laden trunk/boot and/or back seat before it should ever have occasion to kick in. Nothing in your earlier posts suggests to me that you're carrying any sort of a load at all in the trunk/boot or rear seat when you've been doing your testing. Is there any chance you have unevenly "saggy" rear springs? This could play an indirect role by creating an odd geometry for the final drive unit and half shafts. This is just a thought and may not have anything to do with your issue. Brian, who agrees with Randy and is just expanding upon the point | ||

Mark Herbstreit Prolific User Username: mark_herbstreit Post Number: 106 Registered: 5-2005 |

To answer Benoits earlier question of how do you tell if the cushions are ok. My understanding is if they look like a banana they are not ok.  Also there can be evidence of the battery cable that runs between the crossmember and the bodywork being crushed. In my case I could see no evidence of this.  Comparing old and new my cushions are cactus!  The delaney mounts appear to be in sound condition but I will seek an expert opinion. Hopefully this will solve the clunks and bangs. The vibration may be another issue. Randy makes a valid point about the vibration being related to either tailshaft or driveshaft speed. I had considered this when trying to diagnose the problem but found it hard to determine from the drivers seat. I was seriously considering strapping a video camera to the underside of the car to "see" what was going on. This will be my next approach if all the current work fails to pay off.  | ||

Geoff Wootton Prolific User Username: dounraey Post Number: 285 Registered: 5-2012 |

Mark I'm really impressed with your setup. I can see the ramps are bolted to the floor. Is this your own garage or is it a commercial workshop? If you get to go with the video camera could you let us know how you get on. A couple of months ago I purchased an Inland 720P webcam on special offer for $12 to take a closer look at the accumulators on my car. I found the inbuilt leds were not powerful enough to get good illumination so used an additional light source. Worked very well. I presume you will tape the camera to the underside of the car and run the wire to a laptop inside the car. Will be very interesting to see if you can get a good picture - vibration may be a problem. A very interesting experiment that could be used widely as an aid for other owners who are fault finding. Geoff | ||

Mark Herbstreit Prolific User Username: mark_herbstreit Post Number: 107 Registered: 5-2005 |

Hi Geoff. The ramps have proved to be the most useful item in my garage. I did not have the height for a hoist and this way I don't lose any space. They have made life so much easier.  | ||

Brian Vogel Grand Master Username: guyslp Post Number: 586 Registered: 6-2009 |

That ramp is an impressive solution to a problem many of us have. It does, however, require a garage "of a certain depth." Is there any way to briefly describe what those "cushions" are composed of? I've often wondered and after years of being covered by crud, even if they're still in decent shape, it's really difficult to tell. Brian | ||

David Gore Moderator Username: david_gore Post Number: 1324 Registered: 4-2003 |

Hi Brian, If the garage is not long enough, it would be relatively simple to modify the ramp sections and main supports to allow the ramps to be removed when the garage doors had to be closed. Would also mean less chance of shin damage when moving around the car  . . My understanding is the cushions are steel wire formed into a cylinder not unlike a steel wool pad - I have heard them being referred to as "Brillo" pads for this reason. | ||

Geoff Wootton Prolific User Username: dounraey Post Number: 286 Registered: 5-2012 |

Mark Brilliant - and thanks for putting the additional photo up. For us lesser mortals with shorter length garages I guess in addition to David's comment of removable ramps another option would be a pit. I've also seen "half" pits advertised with slidable benches fitted that you sit on. The other option I have looked at is a lift that gets the vehicle 3' off the floor, however from the video I watched it looked pretty precarious to me - not something I would want to trust when getting under a two ton car. Geoff | ||

Randy Roberson Prolific User Username: wascator Post Number: 147 Registered: 5-2009 |

Ramps look great. I have a pair I bought very used: they were originally in a service station-garage in the 1950s and I bought them off a man who salvaged them. They put the tires about 30 inches off the floor. They are scary to drive up on, though; I usually have a spotter assist me. The gold standard, though, is the 2 post or 4 post lift: my buddy who has a commercial garage has both and greatly prefers the two-post lifts.If you have the money and overhead space they greatly speed up work and ease underside access. Being able to raise and lower the car during work is also a big plus. You are really into your Car; thanks and keep posting the photos as they will help all of us eventually. | ||

Geoff Wootton Prolific User Username: dounraey Post Number: 287 Registered: 5-2012 |

Randy I have always wondered if 2/4 post lifts have failsafe mechanisms on them in the event of a hydraulic failure. We are all aware never to trust a hydraulic jack for instance. Obviously this is not the case with hydraulic lifts as they are used so widely. Do you know if it is the case that hydraulic lifts have failsafe brake mechanisms to prevent them collapsing in the event of a catastrophic hydraulic failure? Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 588 Registered: 6-2009 |

Geoff, Though I'm not Randy, I can report on the Rotary lift (2-post) that I am occasionally given access to. There is definitely a failsafe mechanism on it that you can hear operating as the lift lifts. I cannot find any graphic, but from what I can tell, about every 12-inches of lift there are spring loaded "fingers" that protrude that would act as catches if the hydraulics failed. When you want to lower the lift, there is a lever you pull that retracts the "fingers" from the arm tracks to allow the arms to glide back down without getting stopped by those "fingers." What I found particularly interesting is that these "fingers" are not at precisely the same spot for each arm. You hear one clunk out, followed about 1 second later about the other on the opposing side. I'd give my eye teeth (well, I guess not really, or they'd be gone by now) to have that lift in my own garage. [It would help if I even had a garage high enough to accommodate a lift.] I happen to have been under my car while it was on that lift when the one and only earthquake I've ever experienced hit on August 23, 2011. At first I thought that the lift was beginning to have some sort of catastrophic failure. I removed myself from that specific location quite promptly!! Brian | ||

Geoff Wootton Prolific User Username: dounraey Post Number: 288 Registered: 5-2012 |

Brian Many thanks for your reply and yes, I should have entered my query in a more general way. I have always been curious about the above, not ever having seen a garage lift close up. So now I know. I do agree, it would be great to have such a lift. When I eventually become of "fixed abode" I do intend to build some method of getting the car off the ground. I really like Mark's system. I have also read about fiberglass liners that can be bought to make a pit for the garage. All to the future at the moment, but nevertheless of great interest to me. As a brief aside, one of the great things about being able to live in America is I have experienced some very interesting weather and geological phenomema. Spectacular electrical storms in Tampa, a cat 3 hurricane also in Tampa, and I have too experienced an earthquake in San Jose,CA. What I was not expecting re. the eathquake was the shock wave that hit the building before everything started shaking. The only thing I have not witnessed are tornados, which I believe you get in Virginia. These to me would possibly be the most fearsome as they can strike so quickly and without warning. Geoff | ||

Jonas TRACHSEL Experienced User Username: jonas_trachsel Post Number: 37 Registered: 2-2005 |

Some 2-post lifts do not operate hydraulically, but mechanically, i.e. synchronized electrical motors turning a long spindle with the arms reaching under the sills of the car attached to big nuts running on these spindles. Such a system is non-reversible or self-braking, and the brakes attached to the electrical motors dont need much force. JoT | ||

richard george yeaman Prolific User Username: richyrich Post Number: 105 Registered: 4-2012 |

Hi all. On the subject of car hoists my cousin has a four poster outdoors at each corner he has an upright metal post that he has fabricated a roof structure on when he raises the hoist the whole thing roof and all raises up keeps the car dry as well as all the electric motors etc never ever seen anything like it. Richard. | ||

Omar M. Shams Grand Master Username: omar Post Number: 344 Registered: 4-2009 |

I have always been warned about using chassis lifts for cars that have subfames that are attached to the chassis with rubber mounts. There have been instances where Jaguars have been lifted by a two post lift (that has 4 arms) and the whole back end sub-frame (diff assembly and wheels and everything) came crashing down becasue the rubber mountings had failed. Please understand what you are doing whenever you go underneath a car. There are risks that need to be understood and mitigated. Personally, I will not get under a 2 post lift for our cars, but that is me being a wuss. I only get under the car when it is on a 4 post lift that has a track for the wheels to be firmly attached to. That does not mean that I am telling the world to throw away their 2 post lifts. I am merely saying be careful, and I am saying that I am a wuss. This is a subject in its own right and one that has generated enough interest within the group to warrant its own thread. I dont want Benoit's thread to lose its focus as there are many of us watching the outcome of his quest to slove the mystery vibe. May I request that the moderators separate the two subjects so we can keep the vibration and lift discussions alive but separate? Many Thanks Omar | ||

Chris Browne Prolific User Username: chrisb Post Number: 118 Registered: 2-2010 |

Hello everyone, On the subject of the rear horizontal compliance mounts (pan scrubbers, brillo pads etc.), I have replaced these on three Shadows up to now. In Mark's photograph showing the new ones along side the old ones, they both appear to be the same length. There should be one short one and one long one per side (UR14937-short and UR14938-long. The longest one is the rear one and this has to be compressed to about two thirds of its length using a slave bolt which screws into the cast housing before it can be fitted on the car. The slave bolt is removed once the assembly is bolted back on the car to allow the mounting to expand again. They can be described as a series of knitted steel mesh doughnuts one on top of the other held together by a knitted steel mesh sleeve. They fail when the steel mesh becomes brittle and the knitted sleeve holding the doughnuts together bursts open. As well as examining the mounts to check if they have failed, another way is to observe the rear wheels of the car in relation to the wheel arch as you slowly drive the car forward then in reverse several times. If the wheel moves fore and aft more than a couple of millimetres when the car changes direction, this is a sure sign that the mountings have failed. When they have really collapsed, the amount of movement in the wheels is very pronounced. Kind regards, Chris | ||

Mark Herbstreit Prolific User Username: mark_herbstreit Post Number: 108 Registered: 5-2005 |

Good idea Omar. Chris it may be camera angle, the cushions are different lengths 7cm for the short and 8cm for the long. To get things back on track, as suspected the tailshaft unis are stuffed. This is good news as it could be a source of vibration. Also they are common to many vehicles from Rover to Chev.  case hardening on caps has started to disintegrate  | ||

Randy Roberson Prolific User Username: wascator Post Number: 148 Registered: 5-2009 |

U-joints as we call them here in the sticks are often the source of driveshaft vibrations, and I have dismantled several over the years which looked OK on the car, but which, after apart, showed obvious signs of wear. Replacement stopped the unwanted vibrations. Thanks, Brian is right: there are mechanical safety stops for the hydraulic or mechanical lifting mechanism. | ||

Benoit Leus Frequent User Username: benoitleus Post Number: 100 Registered: 6-2009 |

Mark, Thanks for the pictures. I"ll check my car as soon as I'm back from holiday (sipping a glass of rose wine in the Provence  ). ). Chris, with collapsed compliance mounts, could the rear wheel be moving so much it would cause the vibrations and would they increase with speed ? Benoit | ||

Chris Browne Prolific User Username: chrisb Post Number: 119 Registered: 2-2010 |

Benoit, I am really not sure whether or not collapsed cushions could cause a vibration. Their purpose is to locate the rear sub frame but allow some controlled movement of it. If the cushions are really bad, I suppose you may feel a vibration, especially if the sub frame is catching on the floor of the car and you have metal to metal contact. If they have collapsed, you have much greater movement in the sub frame that you should have so I would change them sooner rather than later. There is the added worry that movement in the sub frame may be so great that it will chafe through the battery cable. Kind regards, Chris | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 102 Registered: 6-2009 |

Today I checked the compliance mounts and they are clearly past their best, especially the RH ones (looking like those in Mark's pictures). I don't know if they could be the cause of the vibrations, but they will need replacing anyway. How hard are they to replace and do I need any special tools for it ? Regards, Benoit | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 861 Registered: 9-2004 |

No special tools needed, remember to put some weights in the boot to stop the road springs messing up the correct distances of the cross member mounting points when undone. IMO the u/s mounts do not cause vibration but will cause clonks and a floating front and aft rear suspension. Have you rectified the u/s rack and done the dial gauge checks to the hud flanges? If not you will have so many found faults you will never no what is at the real fault to start with. | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 103 Registered: 6-2009 |

Hi Patrick, I haven't replaced the steering rack yet. It is definitely needed, but as the car was also vibrating on the rolling road I guess it cannot be the cause. As for the hub flanges : I'm still trying to locate a dial gauge to use. What I have noticed is that my car, when put in reverse, has a tendency to "creep up" quite a lot, leaving the back end pretty high. I don't know if this is normal or an indication of a possible problem in the rear suspension. Regards, Benoit | ||

Randy Roberson Prolific User Username: wascator Post Number: 155 Registered: 5-2009 |

With the trailing arm suspension in rear, squat in drive (forward) and rise in reverse is the normal reaction to the forces applied to the drive shaft, hub, etc. | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 109 Registered: 6-2009 |

Last saturday I had the tracking adjusted (it hadn't yet been done since the repairs). As expected this didn't have an influence on the vibrations. However, when driving home, I noticed something. When driving in a straight line and then very slightly turning the steering wheel, the vibrations dissapears for a fraction of a second. It makes no difference if I turn left or right, the vibration will momentarily stop. I repeated this over and over again to make sure I wasn't imagining it. When applying more steering wheel lock, the vibration is still present. Now I wonder how this is possible. Benoit | ||

Omar M. Shams Grand Master Username: omar Post Number: 353 Registered: 4-2009 |

So if I was clutching at straws....... my theory would be that you are seeing the impact of the rear subframe moving slightly the instant you steer away from the central position. In that movement of the subframe, the vibration is momentarily transformed to movement of the subframe itself. After the subframe has moved to the new position, the vibration resumes. The vibration being caused by the subframe floating instead of being restrained by rubber mounts. theory - only theory........... | ||

Mark Herbstreit Prolific User Username: mark_herbstreit Post Number: 109 Registered: 5-2005 |

I have installed the new cushions. This was fairly straight forward with the subframe out of the car. The manual calls for a 5/16 slave bolt to compress the long cushion. My local bolt shop could not supply a bolt long enough so one had to be welded to a length of rod. Also I take my hat off to the people who have achieved cushion replacement in situ without removing the subframe. This must involve extensive use of the swear jar (you would probably make enough to pay for the cushions). The rear long cushion needs to be compressed to insert the short.  rear cushion compressed. Short ready to be inserted  All done with homemade cushion compressor  | ||

Omar M. Shams Grand Master Username: omar Post Number: 355 Registered: 4-2009 |

WOW MARK!!! You must be very proud of that job. That looks a million bucks - keep up the good work. | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 110 Registered: 6-2009 |

Omar, your theory could certainly be a possibility and worth following up. Mark, that looks like an excellent job. I am very interested to see if this will cure the vibrations on your car. If it does Omar's theory is correct and I will know what to do this winter. Benoit | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1121 Registered: 6-2006 |

Benoit, is there a possibility you have a combination of slight wheel bearing play, slight brake disc run out, and a partially seized or sticky brake pad? We always squeeze back all pads each service and remove, clean, and refit the brake pads every other annual service. Many owners would be surprised at how many pads are seized. Visual checking of brake pads is pretty much a waste of time | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 111 Registered: 6-2009 |

Hi Paul, I hadn't thought about that. I do know that with the rear jacked up, the rear wheels do turn quite easily, but I guess the brake pads could indeed still be seized. I I'll certainly check this over the weekend. As for the bearings : when chucking the wheels there doesn't seem to be that much play in them. I still have to locate a dial gauge (altough I might try to make something myself) to see if the rear discs run out. Regards, Benoit | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 112 Registered: 6-2009 |

I just had an "expert" (a non-trained technician) driving my car and he claimed to know why my car vibrates. According to him the differential is to blame and I run the risk of it exploding and causing major damage. I was wondering if this could really be the cause. The diff is not particularly noisy (even if not totally silent),altough it is true that the vibrations improved when I replaced the torque arm mounts. Benoit | ||

Omar M. Shams Grand Master Username: omar Post Number: 368 Registered: 4-2009 |

Oh Dear Benoit. Here is an interetsing question: How many diffs have been reported to have exploded on Rolls-Royces? I have owned dozens of Rolls-Royce/Bentley cars and not one has even come close to exploding its differential. Maybe its over reaction on the part of your expert friend. I would agree with him that the trouble area is the rear end. That is for sure - but the casue may be one of support, not incipient catastrophic failure. I am sure you will find the root cause of the vibration and fix it with less expense than you think. good luck Omar | ||

Daniel Diewerge Experienced User Username: didi13109 Post Number: 37 Registered: 11-2009 |

Dear Benoit, please do not listen to this self called experts with no real experience in RR cars. By the way, reliable dial gauges can be bought for around 20-30 EUR online includig a magnetic holder so I would check wheel bearing play first. Good luck! Daniel from neighboring Luxembourg | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 114 Registered: 6-2009 |

Dear Omar and Daniel, thank you for your support. I suppose the "expert" (who is diversifying from boats(!) and has only limited experience with RR/Bentley's) is really trying to sell me a used diff. Besides, I took the car to the Goodwood Revival this weekend, totalling almost 550 miles, and the diff was not noisy and leakfree. It seemed however that the vibration intensity changed a bit depending on the road surface (generally, the rougher the road, the lesser the vibrations). I'll buy a dial gauge and start measuring. Benoit | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 115 Registered: 6-2009 |

I bought a dial gauge and checked the rear hub flanges, brake discs and wheels. hub flanges : 0.3mm brake discs : 0.3mm wheels (at the outer rim) : 0.6mm right wheel & 1mm left wheel I do not think that these results are enough to be the cause of the vibrations. Benoit | ||

Omar M. Shams Grand Master Username: omar Post Number: 371 Registered: 4-2009 |

Dera Benoit, I agree with you. These results are actually quite good for an old car. You already know where my thoughts are about the cause of your vibes............... Omar | ||

Mark Herbstreit Prolific User Username: mark_herbstreit Post Number: 115 Registered: 5-2005 |

Update A summary of progress so far Torque arm rubber replaced. Diff carrier mounts and diff bearings replaced Suspension cushions replaced Drive shaft Unis replaced and driveshafts swapped left to right. Tailshaft Unis replaced and tailshaft balanced. The good news. The thumps bangs and general driveline slackness have all but been eliminated. The bad news. The vibration is still present however it has gone from the top of the suspension stroke as I outlined in my initial post to the bottom of the suspension stroke. ie when the car is under load when accelerating. It is as smooth as silk whilst cruising. This would seem to indicate swapping the driveshafts left to right had this effect? My conclusion is the problem must be driveshaft/Trunnion related. I was generously offered the opportunity to borrow a complete rear end from a Bentley T that is way beyond economical repair. This involved a trip to the country and other logistics, hence the delay in progress. Hopefully a solution will not be far away. At least it was moving quickly when it met its demise  Driveline removed from doner car. Despite appearences there had been some obvious recent brake work etc. done. I plan to swap it out complete and work backwards from there if it solves the problem.  | ||

Omar M. Shams Grand Master Username: omar Post Number: 384 Registered: 4-2009 |

from what you have said - i would agree with you that it must be the drive shafts. Why not just replace these and see? | ||

Bob uk Unregistered guest Posted From: 94.197.122.71 |

The steering rack Early on you said that the steering wheel shakes If you turn The steering the vibs stop I suspect that the hydraulic pressure that occurs when the demand valve in the Pump detects fluid displacement in rack The pressure damps the rack Using common sense and care and workshop manual adjust the rack damper If this works replace rack the rack fitted when New was rubbish Problems have now been largely sorted Use fully synthetic power steering oil Change 6000 miles} (Message approved by david_gore) | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 151 Registered: 6-2009 |

Hi Bob, I did replace the steering rack, but this didn't do anything for the vibrations. However, when I replaced the front compliance mounts (the originals were split), the vibration became much less pronounced. I also noticed that both rear lower bearing pins are in very poor shape, so that will be my next step. | ||

Chris Browne Prolific User Username: chrisb Post Number: 134 Registered: 2-2010 |

Hello Benoit, For information, I have just replaced both lower rear bearing pins on a 1980 Shadow 2. It is not an easy job as you have to compress the front road spring, with the correct tool, on the side you are working on and release the front anti-roll bar so there is no tension in the suspension. You will then have to separate the rear arm of the lower wishbone from the upright and this is fixed with a large diameter bolt and a smaller diameter bolt. The bolts fasten together the three component parts of the wishbone. The large diameter bolt was not too much of a problem but the small one, on both sides was extremely difficult to get out. The head is quite small, 9/16" from memory, and the only way I could get it to move was with a hexagon socket on a 5 foot long extension bar. Even then, it only just moved and it was eventually pried out using a tyre lever against the head of the bolt as the bolt was turned back and forth with an air wrench. I later found out that these bolts are machined to very close tolerances and pass through three components, all of which make it a very tight fit. At least you now know what to expect! Kind regards, Chris | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 153 Registered: 6-2009 |

Hi Chris, thanks. Your description on how to proceed will be very helpfull. I can't however say it's a job I'm looking forward too. Kind regards, Benoit | ||

Bob uk Unregistered guest Posted From: 94.197.122.93 |

Check the front and rear suspension and steering alignment with lasers Flappy steering is a sign of caster angle being wrong/ Aside comment Rollers are cars which work in laws of physics just like other cars so don't imagine up extra laws (Message approved by david_gore) |