| Author | Message | |||

Randy Roberson Frequent User Username: wascator Post Number: 61 Registered: 5-2009 |

Hi, this is the short "S" tube and I see it is going to leak on my Car; I tried to clean it up but the flare on one end is rusty and won't seal. I need to replace it. Does anyone know the type of flare or if I might be able to make this, or is it "factory only"? I will check with Albers Bentley Monday morning, to see if it can be bought. Anf if I can afford it... | |||

Brian Vogel Prolific User Username: guyslp Post Number: 150 Registered: 6-2009 |

Randy, Where is this item in the Illustrated Parts Manual? I cannot envision what you're talking about (and perhaps that's because my cars don't have it). Brian | |||

Geoff Wootton Experienced User Username: dounraey Post Number: 27 Registered: 5-2012 |

Randy - Do you mean the return pipes from the accumulator valve body to the reservoir?  The lines are relatively low pressure so it would be safe to get your local hose shop to sort something if you can't get a replacement. | |||

Randy Roberson Frequent User Username: wascator Post Number: 62 Registered: 5-2009 |

Hi, Geoff, Brian. Thanks for your interest. No, I replaced the low-pressure rubber hoses: Tractor Supply has the correct EPDM 1/4 inch ID hose, 10 feet for $8. (Oh, the shame! but it fit great.) This is the pipe which connects the pressure pipe from the pump to the front control valve at the top of the valve. I have attached an illustration from the RR parts list; Item 46 in the "Brake Fluid Reservoir Pipes and Fittings" illustration. it's the short,clef-shaped pipe near the page center at bottom. Brian, your cars don't have it, as you say. This is a flared connection of some sort, different from brake flares I think. }

| |||

Brian Vogel Prolific User Username: guyslp Post Number: 151 Registered: 6-2009 |

Randy, Oh, no shame!! Congrats on that find! You can do the same thing with EPDM heater hose of the correct ID for the gravity feed hoses from the reservoir to the pumps. I believe the fitting type you're dealing with is, in all likelihood, a bulkhead fitting onto which this pipe screws. There is an equivalent on the II/2 series ACV where the high pressure line from the pumps screws on to an adapter that has a male fitting facing the pipe and a flat bulkhead fitting, with washer, going into the valve body itself. There is one hose that's used on the II/2 series cars that uses this style:  These equate to UR 19934, 19935, 19936, 19937, 19939, and 19940. When installed they require the use of a copper crush washer, and I'm presuming the equivalent is involved in your case based upon the picture. Unfortunately, I have no record of what flare is inside the line that this flat bulkhead style of fitting goes into. Someone will certainly know, but it's not a bubble flare on the "receiving end," that's for sure. Brian, who'll have something else for his mental files when this thread is concluded | |||

Randy Roberson Frequent User Username: wascator Post Number: 63 Registered: 5-2009 |

Hi, Brian, there was no washer at either end of this pipe when I removed it; the adapter fitting on the control valve may have one under it, between itself and the control valve, though. I remember the ends of the short tube were flared, but not a brake flare, and the ends (male ends) of the adapter fittings were sort of cone-shaped. Because the flare on one end of the pipe was rusty, I had reservations about it's ability to be leak-tight when I reinstalled it, but I went for it, anyway. Soon as I get off the Monday conference call I'm checking if a new pipe is available. Probably $$$. I'll report back. | |||

Randy Roberson Frequent User Username: wascator Post Number: 64 Registered: 5-2009 |

UPDATE: Albers advises the pipe is not available; circa 1972 or so the arrangement of feedpipes from the pumps to the control valves was changed, eliminating the two short pipes with their strange little flare fittings. Repair of the older cars involved replacing the entire piping system from the pump discharge to the control valves with the updated piping system. Not happening. Made of unobtainium, of an unknown design. "We are NOT amused." Queen Victoria | |||

Brian Vogel Prolific User Username: guyslp Post Number: 152 Registered: 6-2009 |

Randy, Take heart. If you've got the flaring tool to make the correct flare for the non-bubble end, or can borrow one, you're golden. Brian | |||

Randy Roberson Frequent User Username: wascator Post Number: 65 Registered: 5-2009 |

No doubt we will prevail; and learn something along the way! I plan to remove the pipe and try cleaning and polishing the flare on the leaking end with some fine lapping compound. I may be able to get it to seal this way. The pipe seems sound otherwise. | |||

Randy Roberson Frequent User Username: wascator Post Number: 66 Registered: 5-2009 |

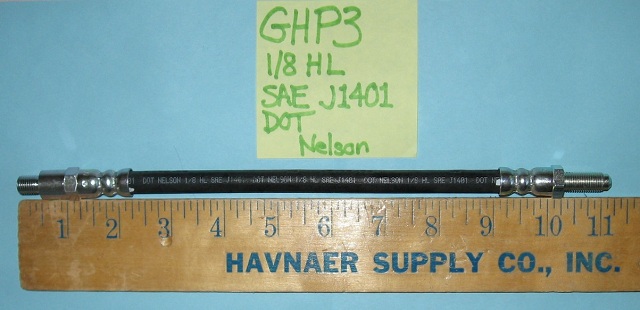

Update: I am pretty sure this fitting is a 37 degree single flare, or AN/JIC fitting. The AN refers to fittings suitable for aircraft use, while the JIC is for industrial use, but they are the same physical dimensions. These parts are readily available if I need to reproduce the line, but I am going to try cleaning the flared tube end, to see if it will seal off. | |||

Randy Roberson Frequent User Username: wascator Post Number: 67 Registered: 5-2009 |

Update #2: I cleaned the flared end of the pipe with a pencil eraser and powdered cleanser, the abrasive kind; then reinstalled it. I will watch for leaks, and if any appear, there is a small cone-shaped washer called a flare seal; developed for aerospace applications and widely used to facilitate sealing a leaky flare joint. I will get some of these and try them. The only problem I see with duplicating this pipe: it is so small and the bends are so tight, that it would be difficult to bend and flare it as the nuts will most likely be in the way. I think perhaps these fittings were silver soldered onto the pipe ends and have the flare made onto the fitting, just for this reason. There are some companies which specialize in tube assemblies for aircraft applications, adn I have no doubt that I can get somethind if necessary, but for now I think it will work as is. At least while researching this I have enjoyed learning about AN and MS fittings. I also have more appreciation about some of the design problems the Rolls-Royce engineers encountered while creating the SY series and the means they used to solve these problems. | |||

Jeff Young Prolific User Username: jeyjey Post Number: 102 Registered: 10-2010 |

Hi Randy, If you try the flare seals, let us know how you get on with them. I've got a few of them in my toolbox, but I've not yet had cause to use them. Jeff. | |||

Randy Roberson Frequent User Username: wascator Post Number: 68 Registered: 5-2009 |

I took SRH9391 for a short drive under her own power Saturday afternoon. Apparently my cleaning work on the flares of the pipe in question worked its magis, as there was not any leaks (yet). The front accumulator bleed vented profusly when I opened it (too far, carelessly; don't do this unless you like RR363 all over you), but there is no flow from the rear accumulator bleed, so I think th epump is not pumping. The front calipers on the front axle bled fine, but again, no flow from the rear calipers. I hope the rear pump is air locked; another possibility of course is that the pump has failed somehow and must come out. If I scatter parts all over the garage, I will of course rebuild both pumps. A least neither has any evidence of local leaking. | |||

Geoff Wootton Experienced User Username: dounraey Post Number: 44 Registered: 5-2012 |

Randy, As you mentioned, I'd make absolutely sure it is not just an air lock before dismantling anything. |