| Author | Message | ||

Carl Heydon Frequent User Username: car Post Number: 59 Registered: 2-2004 |

I need to separate these inner stainless steel and outer mild steel sections of early MK VI wheel covers. Has anyone had experience of this? It appears that a firm press with correct sized support would do the trick, but it may be that the inner has been spun out to secure it. Any clues? Also, does anyone know at which chassis the front wing line was lowered. I know I have read of it but cannot find the reference. many thanks for your thoughts Carl  | ||

David Gore Moderator Username: david_gore Post Number: 1359 Registered: 4-2003 |

Hi Carl, I cannot help with the exact details but the following information may help: I would be surprised if the inner stainless steel section was spun out due to the high degree of spring-back associated with work-hardening of the austenitic stainless steel most likely used to fabricate the inner disc. The most probable form of assembly would be to press-fit the disc into the outer shell using an interference fit and use the inherent spring back generated by the compression of the stainless steel to increase the retention. I would not be surprised if the traditional R-R/B "belts and braces" philosophy was applied and some form of secondary fixing such as punched retaining keepers to keep the centre in place if it came loose in service. If you try to press the centre out of the rim, I would soak the entire cover in penetrating oil for a couple of days beforehand, fill the stainless steel cover with clean sand and use a full width steel plate on top of the sand under the press ram to distribute the load evenly across the centre to minimise buckling from localised stress concentrations during pressing. If you intend reclaiming the outer rims, you will need a wood "dough-nut" pattern profiled to the dished section to support the rim during the pressing operation to avoid buckling. I presume you are going to refurbish the rims so cutting slots aound the I.D. of the rim to release the centres would not be an option. At all times, closely monitor the profile of the centre to ensure it is not pushed out-of-shape if it does not come free easily. Good luck - this will not be an easy job as it is very easy to overload and permanently damage the components if separation is difficult. Regards David | ||

Carl Heydon Frequent User Username: car Post Number: 60 Registered: 2-2004 |

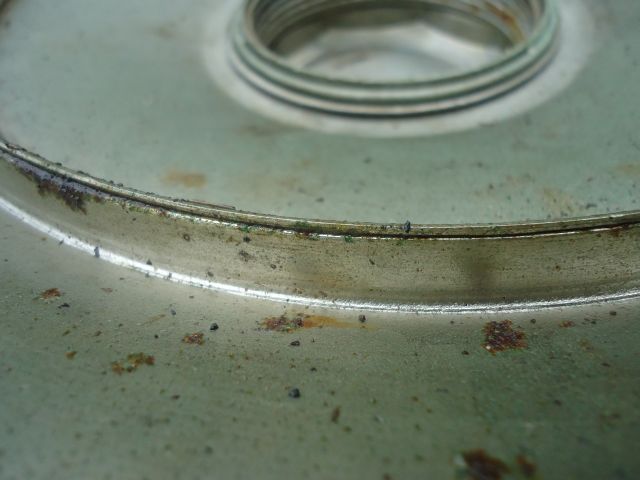

Thanks David, I'm sure you are correct about the spring back. There does not appear to be any other retaining system except for a small lip on the inner that would push through the outer on assembly. I have toyed with the idea of grinding some of the lip off to reduce the grip. I will make a form from body filler molded in the outer with a sturdy ply backing and we shall see.(I wish the outside look like the inside)   Here is the project 6 weeks in  | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 356 Registered: 5-2012 |

Carl I can't help with your problem however I would just like to rave about your fabulous restoration. Looks great. I hope you will post more pics as the restoration continues. Geoff | ||

David Gore Moderator Username: david_gore Post Number: 1360 Registered: 4-2003 |

Hi Carl, The inner lip is the "belts and braces" I was referring to - positive retention by two methods. I have revised my opinion re the press fit as I expected this to be accompanied by some form of straking which could have been ground off with a Dremel. I am now favouring disassembly by a combination of heating the outer rim so it expands the I.D. and cooling the S/S centre so it shrinks its O.D. allowing enough clearance for the centre to pass through the outer rim. Reverse the process when reassembly to components and the resulting interference fit when the parts return to room temperature should lock them securely together. My initial approach would now involve cooling the centre with an ice/common salt mix [a dry ice and acetone mix would be ideal if you can source the dry ice as this will cool to around -80deg Celsius whereas Ice/Salt gives around -20deg C] and heating the outer rim with hot air guns set to maximum heating. This should generate a high enough temperature differential to open up a gap between the centre O.D. and the outer rim I.D. thus allowing them to be separated. If you can access a liquid nitrogen spray bottle used for freezing skin cancers from a friendly doctor, this would be ideal for cooling the outer rim of the centre. The liquid nitrogen will not embrittle austenitic stainless steel [e.g. types 302/304] as they remain ductile at cryogenic temperatures but it will embrittle the mild steel outer rim so do not subject the rim to sudden impact if it is cold. You can get more information on cooling mixtures from the following link: http://en.wikipedia.org/wiki/Cooling_bath David | ||

Martin Webster Unregistered guest Posted From: 200.50.95.2 |

Carl, Have you perhaps thought of heating the disc in an oven if you have one that would accommodate it. It is remotely possible that differential heating could assist you to separate the two parts. Kind regards, Martin Webster (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 1361 Registered: 4-2003 |

Martin, A significant temperature differential is needed to achieve separation of the components and this is why I have suggested cooling the centre and heating the rim. Heating the rim or the entire assembly is very unlikely to achieve separation. I suggest the temperature differential needed will be in excess of 300deg Celsius and the centre would have to be quenched with water to achieve the contraction needed for separation. This quenching procedure is highly likely to cause buckling or distortion which could render further reclamation difficult if not impossible. Carl, You might find the steel temperature color chart on the link below useful [it is not applicable to stainless steel]; just clean portion of the mild steel rim with fine wet and dry sand paper so it is bright and watch the bright metal change colour as heating occurs: http://www.smex.net.au/Reference/SteelColours02.php David | ||

Carl Heydon Frequent User Username: car Post Number: 61 Registered: 2-2004 |

Thank you again David, I will get some dry ice and report back. I will avoid the acetone and accept a slightly warmer center. | ||

David Gore Moderator Username: david_gore Post Number: 1362 Registered: 4-2003 |

Hi Carl, Mea Culpa - just realised there is a significant fire/explosion risk from the acetone fumes being flammable so your decision not to use it proved to be very wise. The dry ice should have no trouble in reducing the centre temperature to around -50deg Celsius so if you heat the rim to a purple/blue temper colour, you should have a temperature differential in excess of 300deg C and the parts should experience a complete separation without having to be forced apart. FYI - the lip on the S/S centre is also common to steel railway wheel tyres which were shrunk onto cast iron centres. The lip served to locate the tyre as the tyre cooled and shrank onto the centre; it never served to retain the tyre in place in service. Watched this process many times in the NSW railway workshops and never ceased to be amazed with the simplicity and effectiveness of this technique. | ||

Carl Heydon Frequent User Username: car Post Number: 79 Registered: 2-2004 |

Hi David, One year later and a tardy response. I ended up grinding the lip approximately 1/3 around and whacking with a rubber mallet. Worked as treat. Painted the wheels body colour and 'chrome' door edge strip to seat on. They needed a large 'O' ring betweenI'm very happy with the result.  | ||

David Gore Moderator Username: david_gore Post Number: 1899 Registered: 4-2003 |

Hi Carl, Thanks for letting us know how you achieved a resolution to your problem. A very impressive finish to a difficult task. The end result is a good example of the "engineer's adage" - "Do not force it, just use a bigger hammer". In saying this, my tongue is firmly planted in my cheek   . . | ||

Martin Cutler Prolific User Username: martin_cutler Post Number: 219 Registered: 7-2007 |

Hey Carl, who balanced your wheel? Why the small weight 180 degrees opposite the 2 weights? | ||

Carl Heydon Frequent User Username: car Post Number: 85 Registered: 2-2004 |

Martin. Only I would be that slack...Probably couldn't be bothered cutting 10g off when there was another 10g sitting there. I wouldn't do it on your car, but mine is fine until I re-balance. |