| Author | Message | ||

James Feller Experienced User Username: james_feller Post Number: 43 Registered: 5-2008 |

Merry Xmas All, Well, I am being more adventourous under the bonnet of my beloved 'Old Girl' For a while I had been noticing a dribble of coolant from the radiator cap which did concern me for 2 reasons, 1, I am terrified of running her low on coolant and also the spotty mess coolant makes when it dries. Of course this all happened a week before Xmas and with the fella's who look after the Spirit for me being away for Xmas. I decided it was time to do a bit of remedial work myself. Up to AutoBarn and 3 minutes later a shiny new recovery system cap was purchased. After I topped up the radiator and coolant reservoir I put said cap on and went for a waft and hey presto no more dribble. I suspect the top seal on the old recovery system cap was a bit cactus. I do have a question though for all you more mechancially minded peoople, the old cap had 15psi/100kpa on it and this new one has 13psi/90kpa... is this something to be concerned about? The guys at Autobarn did not have the 15psi one in stock so I deciced to just get the other one to at least stop the leaking. Thoughts, do I, is it prudent, need the greater pressure one? Cheers J | ||

David Gore Moderator Username: david_gore Post Number: 857 Registered: 4-2003 |

Hi James, The pressure relief rating of 90kpa [13psi] is only relevant if you have a problem with overheating. The coolant temperature required for boiling will be less than that with a 100kpa [15psi] rated cap. This means there will be an earlier venting of the steam from the coolant with the smell hopefully alerting you to the problem if the gauge is faulty or you haven't noticed the temperature gauge reading changing. | ||

John Kilkenny Frequent User Username: john_kilkenny Post Number: 69 Registered: 6-2005 |

Hello James, Unless you have had problems in the past with boiling coolant, the use of a 13 lb cap should be OK. The purpose of the pressure cap is to increase the temperature at which the coolant boils. Boiling coolant reduces the radiator efficiency which leads to increased boiling and coolant loss. For a 50/50 coolant/water mixture a 13 lb cap will increase the boiling point by about 25 degrees C (up to about 130 degrees C) and a 15 lb cap by about 28 degrees, not a great difference. John | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1538 Registered: 4-2003 |

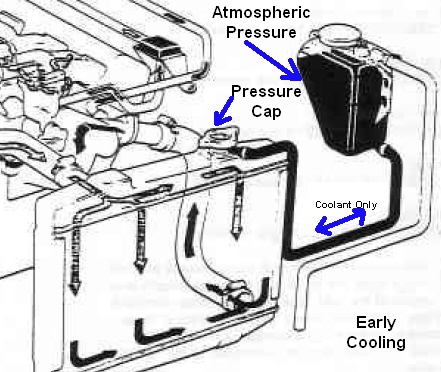

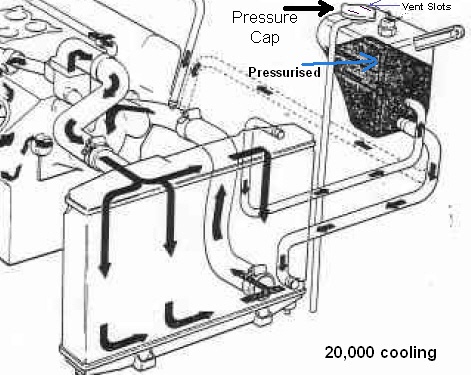

Itís not quite so simple as all that. In summary, there is a warning on cap types. For early cars, be sure of a rubber secondary seal type. Most aftermarket caps are not suitable. ____________________________________ To explain. Assuming that the car is an early type (pre 20,000-series), really a 13% pressure reduction (15 down to 13psi) surely cannot do harm with a few caveats. That is provided that the secondary seal at the larger rim at the top of the cap is a positive one with a rubber seal. The usual sprung metal type will not do. Many, of not most, aftermarket types have the sprung metal type. These allow a certain amount of air venting on cooling when the radiator refills itself. Neither will a 20,000-series 15psi cap work satisfactorily as they are vented at the top. Early and late cars have a quite different mode of operation. The pressurisation on early cars has a secondary purpose to the increased boiling point. That is to ensure that the closed part of the system, the pressurised part, is always purged of air. Unless purged, the system will misbehave and be less effective with air in it. To explain, the early cars have a header tank at atmospheric pressure after the radiator cap. Under normal operation, as the motor warms to the temperature controlled by the thermostat, the cap releases the expanding fluid to the header tank once the pressure reaches 15psi, now 13psi. When the system cools and the coolant contracts, the fluid is sucked back into the pressurised part of the system through the return valve in the lower part of the cap. If the upper part is not completely sealed, some air, possibly only air, will enter as well causing problems. If a 20,000-series cap is used on these systems, it will allow all air and no fluid to return to make matters dire. The 20,000-series cars have a full-flow pressurised header tank with pressurised air at the top of the header tank. When the system heats, only air and vapour escape once the operating pressure is reached. Any escaping fluid is siphoned away by the overflow hose to the ground. As the system cools, air returns to the tank through the vent in the top of the cap (see the two slots on a correct BEHR cap) in preference to sucking any muck up from within the overflow hose. On the pressure itself, the coolant 50/50 mix is slightly compressible, whereas water is more-or-less incompressible. Also, the hoses and matrices expand measurably under pressure, maybe by a total of 400ml or more. If the pressure is too low, excessive fluid will be forced into the header tank, and may overflow. This may stabilise, but the low coolant lamp may illuminate annoyingly when cold. Late systems are more prone to this as the air in the pressurised header tank is highly compressible. This is most apparent on heat soak when stopped after driving hard. The 13psi cap will make this worse, so if the coolant lamp comes on when cold, that is why. If you lose fluid, swap to a 15psi cap. In both cases, the 13psi cap will only allow the system to be filled maybe to 2cm lower in the header tank (early system) and 4cm (late system). Otherwise the system will overflow when hot. The advantage of the late full-flow header tank is that it is almost instantly self-purging of air, even with a bad coolant cap. The early system relies on a perfect cap and time to bleed in minor cases. The early systems need manual purging if the air in the closed system is significant. RT. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1539 Registered: 4-2003 |

Early Cooling System.  SZ 20,000 Omwards Cooling System.  | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1058 Registered: 4-2003 |

Can I add two things to this topic which are related. First the inherant danger in the early system. This was 'discovered' by Bob Chapman's son Neil who realised that if the main bottom hose of this layout blew and emptied the coolant from the radiator the header tank with the level sensor in it would remain full and no lights would be blinking 'help'. The solution here is to install a separate alarm and sensor in the top radiator hose. These are readily available. The hazard with the later system is the 'header tank' bottle itself. No doubt the plastic moulding is carefully made but they can and have been known to burst under pressure. If you happen to open the bonnet while the engine is switched off and very hot,and you are leaning over checking the oil and the thing bursts as has happened, the burns to your body will certainly take your mind off sex for some time! My prophylaxis is to have a towell in the boot which I throw over the tank while I am nearby! | ||

Colin Silver Experienced User Username: colsilver Post Number: 13 Registered: 8-2008 |

Bill said the burns to your body will certainly take your mind off sex for some time! That is dependent on age and genes. I submit to your theory though. In 1979 I opened the radiator cap to my overheated Datsun 180 SSS. Whilst using the said prophylaxis towel, my bare torso got a belting. I spend the rest of the day standing in a cold water swimming pool. My sweet 19 year old wife was the last in my thinking. | ||

James Feller Experienced User Username: james_feller Post Number: 44 Registered: 5-2008 |

All, Thanks for the advice. I have not had any issue to date with overheating. The needle sits at about 4pm once warm and goes about 3pm when in very hot conditions or running quick. I will as a matter of course order the other cap as a precaution. Although the new one seems to have cured the dribble. The coolant bottle sits at its normal marked levels. I will keep and eye on it. My Spirit is an 86 build so it is the early style cooling system as you described Richard. Thanks for the detailed explanation although I now am worried I may have air in the system although there is no bubbling or hissing I can see, yes I did top the header tank up and put a small amount in the radiator but all seems to be fine. As I said, I just had a look then and it is sitting right on the cold line half way down the bottle. When it was hot the other day it was just a bit over the top line marked for hot right at the top of the header tank. I assume this is quite normal. James | ||

John Kilkenny Frequent User Username: john_kilkenny Post Number: 71 Registered: 6-2005 |

James, If the levels in the expansion tank are consistent and close to the cold and hot marks you will not have air in the radiator, as this indicates that coolant is cycling to and from the overflow tank and any initial air locks have been removed. However it is important that when the radiator cap has been removed you check that coolant is up to the radiator neck before replacing it. (Never do this when the engine is hot !) A good quality double sealed recovery type cap is just as good as the RR approved article. With regard to the difference in expansion tank levels due to the 13 lb cap, this will probably be quite small. The amount of coolant transferred to the expansion tank is mainly controlled by the thermostat (i.e. coolant temperature), not the radiator cap. Change in coolant volume due to compressibility is very small compared to that due to temperature and the level difference due to the two caps will depend on the volume/pressure relationship of the cooling system, mainly the hoses; the more variation, the bigger the difference. Regards, John | ||

James Feller Experienced User Username: james_feller Post Number: 45 Registered: 5-2008 |

ta JOhn, Just checked then, engine cold and rad is full and header bottle sittign close to the cold mark line. If I havd over filled it it would have pushed any excess out the over flow tube... As for the recovery cap, they look pretty universal to me, the type Repco or Autbarn had were fairly universal, either a single seal one or a recoivery style one. The one I bought has got two seals on it, a top one and bottom. All seems to be fine, I think I will stop worrying.... ta all J |