| Author | Message | ||

John Ellis Unregistered guest Posted From: 203.220.112.29 |

Could anyone hazard a guess as to why brake fluid would dissapear from the front reservoir on a Shadow II over a few days? There are definately no external leaks, and the self levelling seems to be working well. Could it somehow be escaping into the engine itelf? Hi John, in the absence of any visible external leaks especially at the calipers which are hard to see; the most likely explanation is a leaking piston stem seal in the brake pump which requires removal of the pump for replacement - this seal is often overlooked during pump overhauls and will allow fluid to leak into the engine crankcase. David Gore (Message edited by david_gore on December 01, 2004) (Message approved by david_gore) | ||

whunter Grand Master Username: whunter Post Number: 109 Registered: 10-2003 |

Violent agreement with David Gore. I have seen six of these in the last year. | ||

whunter Grand Master Username: whunter Post Number: 110 Registered: 10-2003 |

Forgot to mention; you will need to change the engine oil and filter. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 124 Registered: 9-2004 |

Hi John, Are both of your dash brake warning lights working ok. Should have about 50 to 90 pumps on the brake pedal before the warning lights come on after running up engine,do test after switching off engine, with ignition swith on. You may have a leak with a diaphragm allowing fluid to enter the Sphere void of nitrogen. | ||

Robert Chapman Grand Master Username: shadow Post Number: 130 Registered: 5-2003 |

Hi John, If your leak is a continuing one and you have to keep refilling the front chamber over and over it is more likely that you have a leaking pump as the acc/sphere can only hold so much fluid. (And the pumps can leak without the engine running). The brake pumping method in my opinion is only a rough guide at best and relies on the correct operation of the low pressure warning switches,which are notoriously temperamental. The only accurate way is to test with gauges. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 135 Registered: 9-2004 |

Robert Read the first post. ie definately no external leaks. There would be if you were topping up continuasly Surly proceed with my rough test as you call it first. I am wrong yet again! | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 136 Registered: 9-2004 |

Robert are you saying switches when faulty just ignore them, i say they are reserve high pressure switches. As Bill C once stated Check them at the end of a trip,i think about once a week! | ||

Robert Chapman Grand Master Username: shadow Post Number: 133 Registered: 5-2003 |

Patrick,calm down,I am allowed an opinion ,as you are. Nobody has said you are wrong again! If John has to CONTINUALLY top up and there are NO EXTERNAL leaks then it must be going into the engine as whunter and David have said. The switches are definitely not pressure reserve switches since they will go out with no gas pressure at all in the sprere as long as the engine is running. They are low pressure switches. I certainly did not say ignore them,(read the post again)I said they were a guide only and that gauges were the most accurate way ,would you not agree with that. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 138 Registered: 9-2004 |

Robert i agree. However if the fluid was passing the pump when left standing,i would expect the oil in the sump to show rise on the dip stick? Maybe the topping up would stop to confirm the diapram if the Sphere was full? | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 473 Registered: 4-2003 |

By the way, to complicate the pedal pumping ambiguity, US and Australian-spec Shadow IIs, and replacement pressure switched for earlier cars in those markets, have different pressure switches from UK-spec cars: they switch at a far higher pressure. This is borne out in the spares schedule. Owners of Shadow Is, used to the lamps extinguishing instantly, get very cranky after spending a fortune on the hydraulic, with new pressure switches, only to find that the lamps take minutes to go out after a few weeks parked. They also worry that it takes far fewer pumps for the lamps to come on, and that sometimes they can come on after parking overnight. This highlights the approximate nature of the pedal pumping test. Having said that, the pedal pumping test is always a useful first diagnosis. It will certainly show up a very low or ruptured accumulator sphere. Especially, if you are familiar with your car, a periodic pedal pumping test will give you an instant warning if something has changed for the worse and that a pressure test is due. Also, in all cars but expecially in cars with a master cylinder, you can feel the pedal go suddenly dead when all pressure has finally gone, regardless of the lamps. Of course, the pumps have no seals: they only have a few static o-rings. They rely on seepage past the piston returning to the reservoir via the atmospheric-pressure return cavity down the bore. Slight seepage into the crankcase is normal but should not be detectable. Noticeable fluid loss can only really be due to the lower pump o-ring being ruptured. O-rings are cheap: too often, pumps are replaced for quite a high price when only the o-rings need replacing. | ||

whunter Grand Master Username: whunter Post Number: 116 Registered: 10-2003 |

Very little fluid passes the pump when left standing. Most of the fluid passes the pump while running. The volatiles boil off, and what is left in the engine oil destroys lubricity of the oil. The oil level in the sump does show a slight rise on the dip stick, volatilization depends upon engine temperature, which controls how much you will see upon the dip stick. If ignored or misdiagnosed; the cam shaft is at very high risk of destruction. All bearing surfaces will suffer degradation. | ||

Bill Coburn Grand Master Username: bill_coburn Post Number: 292 Registered: 4-2003 |

Hey surely a Hell of a lot of brake fluid would have to get into the sump to make the level rise visibly? Somewhere I pointed out that one indication of fluid entering the sump is that the oil filler gasket takes on a rather obvious glazed look | ||

John Aravanis Unregistered guest Posted From: 213.5.27.193 |

Speaking of pumps and switches, and just when I thought it was all over (after replacing all components of the braking/rear leveling system except caliper seals and accumulators/valves), the front system warning light will go on for 2-3 seconds upon start up even if the car will stand overnight. Before that the light(s) would stay off even after 15-20 days of not using the car. And yes.....I have 5-7 pumps on the pedal to get the front system light glowing. Question is, can I check the front accumulator pressure and recharge it on the car? A local Citroen dealer said that he could check the pressure and recharge the sphere if it has lost its pressure from the charging point. Otherwise should I remove the sphere and replace the diaphragm? I have heard that the accumulator valves rarely go "bad".Car is a '70.(SRH 8685) (Message approved by david_gore) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 476 Registered: 4-2003 |

John, Considering the recent work done, you probably just have air in the system. Give it a bleed before committing to anything expensive. In any case, you are very lucky: your Citroen guy is very generous to offer a test and recharge. Take him up on that. He can do it in-situ, but it is a good idear to remove the spheres and replace the o-rings (sphere to valve body joint) every few years anyhow. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 147 Registered: 9-2004 |

Robert, Been thinking on the swiches to as what they are called. I think they are just pressure switches. Let me explain if you have full nitrogen pressure in the spheres,on start up and if engine is running and one pressure warning light is on it is telling us there is no pressure,ie broken push rod on pump or pump broke etc. So must be pressure switches? Do you agree? | ||

whunter Grand Master Username: whunter Post Number: 118 Registered: 10-2003 |

They are LOW pressure warning switches. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 149 Registered: 9-2004 |

Whunter,in that case what low pressure are they set to come on! | ||

whunter Grand Master Username: whunter Post Number: 119 Registered: 10-2003 |

In this case; I shall ignore OEM service material, you can find it in the Shop Manual or call your local dealer. The variation I have seen is "Never" too 2,100 psi, and this is why so many people warn, don’t trust the warning light as a diagnostic tool. The wide variation is due too maintenance, age and training/knowledge of the rebuilder. Only a devoted DIY enthusiast or well trained mechanic will make the effort to clean and rebuild it correctly, OEM mechanics are presumed to be fully trained. You must attach a gauge for diagnosis. Any diagnosis done without a gauge reading is guessing. The Low pressure sensor has only one function: “You have a dangerous failure in this system”. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 150 Registered: 9-2004 |

Whunter you have missed the question. What pressure do they come on if they are low pressure switches. | ||

Robert Chapman Grand Master Username: shadow Post Number: 135 Registered: 5-2003 |

Patrick, I think you have answered your own question,you said"if the engine is running and one pressure light is on it tells us there is no pressure". The switch does not measure or indicate pressure at any other time other than low. The low pressure it switches at(earth) is initially pre-set by the spring pre-load, (ranges between 600 and 1000 psi)but in service this setting alters,the diaphram indents,the bakerlite plunger barrels and sticks in the brass disc. When this happens the result is either the light will not go out even though pressure has built up or will not come on even though there is no pressure. I would estimate half of all light problems we see are caused by sticking switches. This is why I say they are a guide only and once the engine is running,and the light goes out they give absolutely no indication to the amount of stored hydraulic pressure reserves. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 152 Registered: 9-2004 |

Robert. Thank you for the correct explanation. And now the final Question. Most switches fail safe so do these when working. | ||

Robert Chapman Grand Master Username: shadow Post Number: 136 Registered: 5-2003 |

Patrick, In my experience the majority of failures ,are in the unsafe position,that is the lights don't come on. The danger scenario here is that the driver gets in the car starts the engine ,no red warning light come on,so the driver assumes all must be OK. He has no idea that one pump none return valve is leaking back and only holding 25% pressure,and the other sphere has no gas, and he only has 2 applications of the brake in the event of the engine stopping. This is a good argument for regular use of the pumping out method as a guide,something I would strongly advocate all owners to do.And then when any difference in behaviour is noticed, have them tested by pressure gauge. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 155 Registered: 9-2004 |

Robert,Thanks for your reply on the switches,I had a faulty one that never came on after i fitted a replacement diaphragm. After takeing it apart with a good clean it has been ok ever since. Think i would be happier if i had a pressure gauge on just one circut fitted below the dash! | ||

whunter Grand Master Username: whunter Post Number: 120 Registered: 10-2003 |

You would need two gauges, one for each system. To be of any use, they would need to be in driver view area, in dash or on top of dash. I have never found a way to do this; that would be ok with owners or concourse judges. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 156 Registered: 9-2004 |

Whunter,just one would do as a saftey precaution back up,so you would always know one circut is Ok. How about the left inside panel of the glove box. | ||

whunter Grand Master Username: whunter Post Number: 121 Registered: 10-2003 |

Hmmm Two transducers and LCD readout would be less intrusive. | ||

David Gore Moderator Username: david_gore Post Number: 345 Registered: 4-2003 |

Great work mates and whunter's suggestion is one well worth following through:- Do we have anyone with enough electronics ability to "spec-up" a suitable unit? My suggestion for the transducer would be a suitable strain gauge bonded to the outside of each high pressure feed line from the accumulators to the distribution valves. The use of a suitably calibrated strain gauge would eliminate the need to "break-into" the hydraulic system and it would also be fail-safe in that any malfunction would result in a nil pressure reading. | ||

whunter Grand Master Username: whunter Post Number: 122 Registered: 10-2003 |

I shall speak with an automotive electrical engineer. The prime issue will be getting a car to experiment on. Getting the strain gauges positioned correctly, and assembly of a low cost system will take time. Transducers may be cheaper and more accurate, but all avenues will be explored. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 159 Registered: 9-2004 |

whunter,great idea if one could have just two or four LEDs, green Ok, red Warning, elderly folk can't see the LCD so well as lights. | ||

William H. Trovinger II Grand Master Username: bill_trovinger Post Number: 182 Registered: 8-2003 |

Whunter; Have you considered looking at the software that kids are using for street racers? My knowledge of these systems is very limited, as in my youth horsepower was all we worried about. However, as I understand it, this stuff can be set to give all different type of readouts (head temp, boost pressure, fuel and nitrous follow, even air pressure for those jumping bean cars) and on anything from Laptop to PDA. They can show simple digital readouts or on larger screen (laptop) simulated analog gauges. Granted some are linked through existing onboard computers but others have separate sending units at all points being monitored. Biggest scare is someone would be too busy watching the readouts and forget about the road. Best regards, Bill | ||

John Ellis Unregistered guest Posted From: 144.137.190.68 |

Hi Guys, I want to thank you for all the wonderful interaction to try and solve my problem. Now I have had time to think and observe a little more. Firstly the reservoir seems to empty itself only when being driven, and sometimes it doesn't go down at all despite being driven. When garaged it stays the same. It only takes a few days to empty when it decides to do so. I have observed fluctuating engine oil levels, sometimes reading a little high. For about 1 year it has had a noticeable ticking type sound that eventually goes away when the engine is warm and was told that it is the brake pump and not to worry about it. Could this have been the warning? My mechanic tells me that the pump could be around $800 to purchase and similar for labour. Perhaps all it needs are "o" rings?? An oil sample from the sump was sent away for analysis just to make sure, but the lab lost it......bugger, no car for Christmas. John. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 350 Registered: 4-2003 |

John, Someone once told me they thought the pumps were based on a CAV diesel injector pump and based on my experience in reconditioning them; I think this could be correct. Injector pumps are designed and assembled to allow a very slight leakage of fluid past the piston for lubrication purposes only and the bottom O ring seal is purely to contain this leakage. If the pump is worn/scored then the amount of leakage cannot be controlled by the seal and it will escape to the surroundings. I would remove the pumps, replace all the seals and take them to a diesel injector specialist and ask them to do a leak test - if there is minimal leakage I would reinstall; if significant leakage exists get them to check measure the bore and piston for wear and ovality and see if they can recondition them for you. If reconditioning is not possible then you have to look at the purchase alternative and salvage the seals for future use from the old pumps. I suspect your ticking noise was the classic V8 hydraulic lifter noise and not a noisy pump as this should be present at all times regardless of whether the engine is hot or cold - a quick check of both pumps with the dipstick as a stethoscope will reveal if the pump[s] are at fault - some ticking is normal but it should not be harsh or metallic indicating excessive clearance between the pushrod and the piston due to incorrect set-up when re-installing the pump or [worst case scenario] a worn camshaft. Some "heavy" ticking may be heard immediately after start-up if your accumulators are low on gas charge and the pumps are working effectively under "open-discharge" conditions until sufficient back-pressure exists in the system to cushion the pressure pulses. When are you checking the fluid level - straight after you garage the car or next day? If you are checking immediately after use, the levels can be affected by the amount of fluid in the self-levelling rams and accumulators which bleeds back to the reservoir over time - a reservoir which appears low immediately after being garaged can read full after 24 hours standing for this reason. I may be guilty of teaching you to "suck eggs" on this but it is something that you need to be aware of. (Message edited by david_gore on December 22, 2004) | ||

David Gore Moderator Username: david_gore Post Number: 505 Registered: 4-2003 |

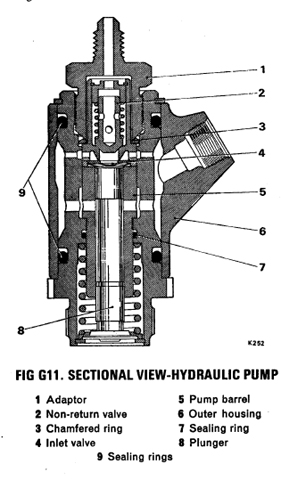

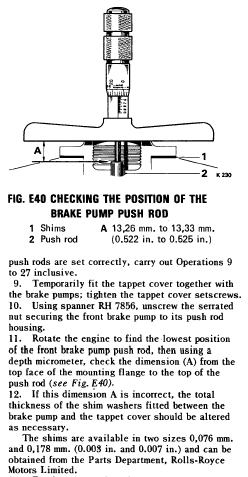

The following diagram is in response to a query on this topic from the Swammelstein Forum. The piston seal is item 7 on the following diagram:  Setting the pump pushrod clearance is as below:  |