| Author | Message | ||

bob UK Unregistered guest Posted From: brig-cache-4.server.ntli.net |

I went to the local diy shop and on the way back my brother in law said that his window would not shut( rear left) Back home checked the fuse fuse OK. Now I have a problem. Rather than charge at like a bull in a china shop and take the rear door panel off I decided that I would have a cup of tea and a think. I visualised the circuit in my head carefully going through the circuit. The window motor when at idle has both feeds positve and when a switch is operated the switch disconnects one live feed and connects it to negative ( earth). The motor wires are connected to the common of a pair of micro switches with another pair connected in parralel on the drivers door. The positive comes from the fuse to the drivers door switch pair of micro switches and is connected to BOTH normally closed contacts. The normally open contacts are conected to negative (earth). The two live wires then go to the normally closed contacts on the rear door micro switches. The normally open contacts go to negative (earth) When a switch is moved ONE of the micro switches is operated and the contacts join the common (which is connected to one side of the motor )to the normally open contact which is negative. The motor now has a live and earth and the window either opens or closes and versa versa if the switch is moved the other way. If the drivers door switch and the passenger door switch are operated in different directions the motor gets two earths and does not work until someone takes their finger off the switch. any number of door switches can be added and the system will still work. All of the above is what I was thinking about. I then thought about what I did last time I worked on the car. Last job was fitting a Loudspeaker to left front door ( right hand drive car SRH 17768 ) The loom for the rear door goes into the middle post then out of the post by the seat belt along the sill under the carpet under a piece of trunking then it connectes via a 11 pin socket/plug to the dash loom. Always suspect plugs and sockets after the fuses. I have only seen one wire broken under the insulation and that was on a brand new loom, if it did work it is very rare for the actual wire to be faulty away from the conector(s) The plug is behind the kick panel in the foot well. Remove the panel and try to pull the wires out of the housing. A blue wiring came out and was green on the end-- verdigis- copper corrosion. The pins can be replaced but I haven't got any. So cut the wire the other side and splice a short piece of blue wire in solder and fit blue heat shrink sleave for a top class never go wrong repair. before sleave is heat shrunk I smear the wire with vaselin. The blue wire is one of the lives for the motor. The solenoid brake is wired in parallel with the motor and is not polarity consious The window now works and the total cost was pennies and the time taken was 30 mins for the repair and about 30 mins thinking time. I hope that this gives and insight into how engineers work. LOGIC. So next time you see a mechanic sitting down with a cup of tea he is usually thinking about the fault not being lazy. Also the reader now knows exactly how the windows work and when they don't will not have to guess how they should work (Message approved by david_gore) | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 644 Registered: 9-2004 |

And the most causes of Shadow corroded connectors and terminals within the interior is down to waterleaks. First signs are heavy condensation forming on all the glass. Do check under the front carpets for any moisture, This can be a big floor replacement job if left unchecked together with the electrical repairs on-going. | ||

John Kilkenny Experienced User Username: john_kilkenny Post Number: 27 Registered: 6-2005 |

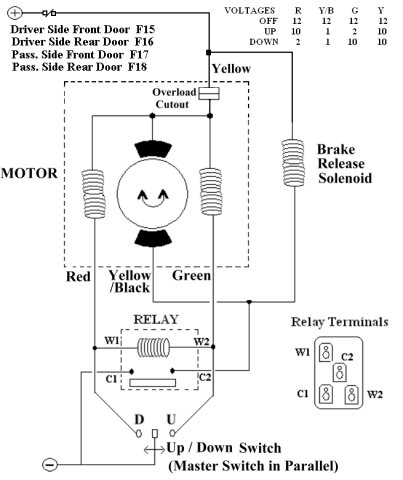

Because the inside of the doors tends to retain moisture even with the sheet plastic shield in place, long term corrosion can occur where wires are joined, for both crimped and push-on fittings. The use of a switched earth means that most of the connectors are sitting at +12 volts which may also make long term corrosion more likely. It is important to ensure that the door drainage holes are clear so that water cannot remain in the door. Another possible cause of window lift failure is brushes sticking in their holders after prolonged non-use, so it is a good idea to operate each window once a week or so. The full operation of the window lift circuit can be seen by referring to the attached diagram. When either the up or down switch is made, the selected field winding receives full voltage. Because the non-selected field winding will be connected via the relay winding (which has a resistance several times higher than the field winding) it will receive only a small voltage, not enough to affect the motor direction. The operation of the relay will cause the necessary higher current to be applied to the armature winding and the brake release solenoid, so turning the motor in the selected direction. This clever circuit also allows for the master switch and individual door switch being operated in different directions at the same time. Both field windings will be energised but the relay will not operate, so the armature and brake release solenoid will not receive current.  | ||

bob uk Unregistered guest Posted From: brig-cache-4.server.ntli.net |

Moisture is the sworn ememny of electrical connections. Petrol Jelly or vaseline combats the effects well. Holts used to make a red jelly in a small green tube called Non-corrode which was marketed for battery terminals. This stuff is better than vaseline also the red colour makes it more obvious that the terminal/connector has been so treated. Whenever I disconnect anything I always use vaseline on reconnection if required . Quick way of cleaning battery terminal is Hot water. If anything is added to the water such as bi-carb it may leak into the battery via the vents and ruin the battery. Over cleaning an engine compartment with de-greasers can do the same. For copper based terminal etc ( brass usually ) corrosion can be removed with vinegar or cheap wine or citric acid such as a lemon. I once impaled a pickled onion on a fuse terminal overnight and the terminal came up bare clean metal. I work with boats, and sea water is even worse. Strickly speaking a crimped connection is better than a soldered one, but we often reject crimped terminals in favour of soldered ones. Always take a good look at connectors in wiring because they are the weakest link in the chain. When I am in a traffic hold up I play around with the switches etc it keeps circuits working. In particular, the heater switches need working once a week to keep the servos good. (Message approved by david_gore) | ||

Paul Yorke Experienced User Username: paul_yorke Post Number: 11 Registered: 6-2006 |

Only things I'd add are: I usually spray WD40 or silicone spray around the whole inside of the door, this stops the moisture lingering around as long. When trying out all the switches, do the window ones on the way home! | ||

bob uk Unregistered guest Posted From: brig-cache-4.server.ntli.net |

I use Finnigans wax oil inside doors. 2 colors black or biege, black underside and biege elsewhere. I buy it in litre cans that screw on to my Shultz gun. If a lolly pop stick is wedge between the glass and the rubber on the out side of the door a squrty oil can nossle will fit and inject wax oil in to the door cavatity. Do with doors open because the excess drips out of the bottom drian slots. and clean glass after wards. And when the oil is waxed semi solid poke the drian slots with a small pokey thing. Wax oil by capilary action will coat the insides of door seams and flanges which is particularly important with steel doors, also will stop any steel to aluminium corrosion. If it moves oil it, if it doesn't move wax oil it Except some plastic bushes and rubber and exhaust. Wax oil is easy to remove with white spirit and WILL NOT damage any car paint finish or type. (Message approved by david_gore) | ||

Billy Unregistered guest Posted From: cpc1-epso1-0-0-cust154.hers.cable.ntl.com |

All previous comments are quite correct - e.g. corrosion, sticking brushes etc. but this may be of interest. Make absolutely sure you are getting 12V at the motor. The left rear door being furthest from the switch pack (on a r/h drive car) can excperience volt drop and experience has shown this to be critical. It may be necessary to run 17A cable to the motor, from the switch pack or fuseboard and utilise a relay. Hope this helps.}} (Message approved by david_gore) |