| Author |

Message |

Patrick Lockyer.

Frequent User

Username: pat_lockyer

Post Number: 28

Registered: 9-2004

| | Posted on Saturday, 30 October, 2004 - 09:36: |    |

Back from hols,and just to put my few words on the subject.

Yes there is a weakness in them and a great number of other manufactures ones as well.

However only mostly brought about by little or faulty maintence ,this seems not to have been mentioned on this forum so far.

1.incorrect torque setting of the locating nut on the rocking shaft over time.

Should be released and retorqued every couple of years to 200lb.ft

2.Wheel dynamic out of balance.

3.brake disc distortion.

4.Tyre run out and flat spots.

All these probs if not delt with will cause stress movement on the taper with failure of the arm and yes even with the later type arm.

Do not get paranoid about failures if the above are carried out and delt with in the maintenance schedule times no failures will occur even after many years and miles.

The uk annual mot test,it is also a requirement to check and test for any faults with the arms.

|

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 408

Registered: 4-2003

| | Posted on Monday, 01 November, 2004 - 03:17: |    |

Now that this Pitman arm topic has its own thread, can I pose a few questions.

Pat don't take this as hostile in any way, but:

This is surely no maintenance issue.

You cannot seriously suggest that a 5 year old car should have its Pitman maintained. Nor should a car of 105 years of age. Most Shadows were 5 years old when their drop arm levers failed. Ours happened to be 28: a well cared for car, and I can assure you that the steering box had never been touched. There is a downright design fault in these Pitman arms.

Sorry.

As for the UK MOT, you are lucky if they kick the tyres. It is a complete joke. Rust: no problem, oil leaks: no problem, steering play: no problem. Having seen many UK cars, R-R included, with new MOT I have no respect for the quality of the tests.

The most thorough test in Australia was always in the ACT (Canberra), but they gave up as it was too expensive and most cars were too new or well kept to fail anyhow. It is now a random check system: never park a defective vehicle in a car park or you may return to find a defect notice on your windscreen if you even have just rust bubbles. I hated the thorought ACT yearly tests, but they served a purpose.

I have been accused before of poor maintenance causing this failure. I think it absurd that I should ever need to re-torque such a fundamental safety component during maintenance. That would be a world first. No respectful engineer would include that in a scheduled maintenance regime. These cars should have been recalled as a "A" matter, ie obligatory and urgent, in my opinion. Any other manufacturer would have done so. The same applies to the final drive crossmember. Instead, the changed pitman arm design, revised final drive crossmember and reinforced final drive torque arm were all modified without reference in any service bulletin. Our final drive crossmember was modified around 1977 by the main dealer with no entry into the service records and no invoice. Make up your own mind.

Robert C., if you read this, you say you have found three cracked Pitman arms recently. Out of how many tested was that ? Out of interest, are you prepared to say how you detected the cracks (magnaflux, X-ray, ultrasound, infrared etc) ? I will understand if you decline to do so of course.

In any case, I can assure any reader that Robert is providing a really important service here, and is certainly not trying to drum up business. If you have ever experienced a sudden loss of steering, or any other fundamental loss of control, you will certainly understand. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 33

Registered: 9-2004

| | Posted on Monday, 01 November, 2004 - 07:26: |    |

Richard it is in my opinon that it is a must to have any of the above delt with strait away or certainly in the maintenace schedule.

As i have said there is a weekness there and any vibration on the steering puts loading to eventual

stess movment on the joint.

I am not implying that any one is trying to drum up business through not doing the checks and having failures.

As for the mot checks i am sure you are out of date on the proceedure in the uk.

If you know diferent i would only be to pleased to have the testing station no and discipline i assure you will be followed up. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 409

Registered: 4-2003

| | Posted on Monday, 01 November, 2004 - 07:54: |    |

Hello Pat,

Again, not trying to be aggressive, but I can e-mail you a 2003 letter from the MOT to me after I complained about their negligent practices. It will stun you. All care, no responsibility etc.

I don't believe that over the last 18 months' a revolution has occurred in the MOT.

eg Point 4 of the letter:

"4. The sale of unroadworthy vehicles present (sic) difficult problems since offences are not normally discovered until after the vehicle has been finally purchased. It is the Department's policy to advise the buyers of used vehicles that the most effective measures they can take to protect themselves is to have the vehicle thoroughly examined before completing the purchase.".

This was after a car (not mine, but a 7-year-old Bentley nevertheless), was passed by the MOT before purchase, and then immediately banned from use the next day by the police. The 18 month West London comprehensive warranty was practically useless.

This chief really means that the MOT is for nothing: you must have an independent test, and the MOT takes no responsibility for roadworthiness at all. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 410

Registered: 4-2003

| | Posted on Monday, 01 November, 2004 - 08:32: |    |

Basic stuff:

Front brake rotors more than 3mm worn. Steering rack leaking (unfortunately common) and too much play, rear road spring supports rotten, seatbelt missing from the centre rear, heater inoperative, damaged fuel lines. The police noted the seat belt problem, and the subsequent check revealed the rest.

The non-safety items were something else, and all in a fairly new car. Company car for sure. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 34

Registered: 9-2004

| | Posted on Monday, 01 November, 2004 - 09:08: |    |

Richard.

I forgot to mention bump steer on rough roads it is a killer for the pitman arm and another important item to be delt with in the service schedule.

Will get back on the mot failings |

Robert Chapman

Prolific User

Username: shadow

Post Number: 98

Registered: 5-2003

| | Posted on Monday, 01 November, 2004 - 11:07: |    |

Pat Lockyer.

This latest fallacious post of yours is really verging on professionally irresponsible.

Even on such a serious safety subject as this you cannot control your puerile and transparent obsession to contradict

Your contrived suggestion that this failure can be prevented by a change of service schedule is grossly misleading and could put owners and other road users lives at risk.

Your statement that even the new design arms can fail if not “maintained” is blatantly incorrect.

The dangerous thing is that you are prepared to make such categorical authoritarian statements as

”no failures will occur” on this forum and that some owners / readers may take your advise seriously.

I believe the contents of this post is grossly irresponsible, I think you should remember that peoples safety could be put at risk by your self serving advice and that any safety related advice needs to be absolutely correct.

|

John Dare

Unregistered guest

Posted From: 144.138.194.182

| | Posted on Sunday, 31 October, 2004 - 21:28: |    |

I havent heard (even a rumour) or read (even a snippet) about other makes of cars/trucks which had inherently weak Pitman arms which were prone to instant failure (at any point!) without "notice", the consequence being immeadiate loss of directional control. The potential for culpable liability beggars belief!. R-R have long suggested that hyd. hoses on Shadows be replaced at 96000 mls. (irrespective of their "apparent" condition) however I remain unaware of any requirement, explicit or implied, calling for periodic re-torqueing of Pitman arm retaining nuts in a manner/time frame similar to say,cylinder head bolts/nuts, the latter being a common requirement upon a variety of auto engines, past and present. If these recorded (and CONTINUING!) pitman arm failures were the result of poor maintenence or "neglect" (real or imagined) you can bet your booties that R-R would NOT (repeat N.O.T!!)coyly "offer" replacement/s with a visually more robust (thicker/enlarged) retaining "boss" area, on a free of charge basis. IF you complain and say your are related to Ralph Nader you will probably get one. Dont ask me how I "know" this.

(Message approved by david_gore) |

David Gore

Moderator

Username: david_gore

Post Number: 325

Registered: 4-2003

| | Posted on Monday, 01 November, 2004 - 18:13: |    |

Gentlemen and others,

This problem has finally dragged me out of "retirement" and my metallurgical curiosity has got the better of me so I am attempting to get hold of some cracked arms for inspection and/or [with the owner's permission] detailed examination to determine the mode of failure.

Watch this space for developments HOWEVER I suggest ALL Shadow owners should have their Pitman arms checked for cracking as soon as possible if you haven't already done so. The consequences of even one car having an undetected problem and the security of knowing your car is safe are enough justification for the cost of this inspection. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 411

Registered: 4-2003

| | Posted on Monday, 01 November, 2004 - 18:24: |    |

David,

I'll check whether I still have the cracked Pitman arm. If so, I'll have it posted to you.

Usually I throw useless bulky items away, but I may have kept this spectacular gem for posterity.

PS it may be a little spoiled. I tack welded the crack so I could at least manoevre the car gently into the garage while we awaited a spare. The first replacement I received was presumably for an earlier car and did not fit, so the car was out of action for two weeks until the correct one arrived.

RT. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 35

Registered: 9-2004

| | Posted on Tuesday, 02 November, 2004 - 00:03: |    |

Robert Chapman.

Preventative Go to the route cause and somthing you don't always find in the factory schedule or manufactures bulletins.

Can only be learnt from years of expierence and comonsence, somthing i pass on when needed.

I hope that all folk take my advice seriously.

Crewe would even at this late stage of time do a recal if was a serious issue.

It is a known fact that there is a weekness by the fact of a modified arm.

Rest assured [AFTER THE HORSE HAS BOLTED]that after fitting the modified arm the other faults that have not been delt with will in a longer time

render problems on the taper.

Mabe RR have excepted that there is diferent stadards of workmanship carried out and of which they have no control. |

Robert Chapman

Prolific User

Username: shadow

Post Number: 99

Registered: 5-2003

| | Posted on Tuesday, 02 November, 2004 - 16:50: |    |

Pat,

How could you possibly expect anyone to take you or your advise seriously,when you make such ridiculous STATEMENTS as "the arms will not crack if you re-tension the nut every 2 years" and "if it was a serious issue".

What could be more serious that a total instant loss of steering I would like to know,OF COURSE ITS SERIOUS.

As for you passing on your "experience and commonsense",you must be having a laugh ,this must be a wind-up.

I have never read anything from you that remotely resembles or indicates either.

Do you think you are the godfather of the motor industry,what makes you think you are the only one with years of experience.

As for "different standards of workmanship"I bet R-R never in their wildest dreams(who would) thought there would be some nutter out there loosening and re-tightening the pitman arm nut over and over in order to stop it cracking?.

Do you write this stuff to offset the boredom of irrelevance or simply just a wind-up.

And I thought Jerome Beadle was good,you had Richard, John, and myself all going there, we all thought you were serious!What is this, have a laugh at the Australians week. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 39

Registered: 9-2004

| | Posted on Tuesday, 02 November, 2004 - 17:44: |    |

Robert.

Nothing like an alarmist posting from you yet again and we all know why that is.

can't grasp the underlying cause of the problems either.

I WILL REPEAT.

1. DYNAMIC WHEEL BALANCE.

2. BRAKE DISC DISTORTION.

3.TYRE RUN OUT AND FLAT SPOTS.

4.BUMP STEER BY INCORRECT SET UP ETC ON ROUGH ROADS.

All of the above will cause stress on the pitman arm,old type or new.

So you are saying do not bother with the stated faults or that they are of no concern to the issue.

I put it to you that your many arms found with cracks in them point directly to my above statement.

To clarify further to your failures please give the percentage of cars found with the cracks. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 40

Registered: 9-2004

| | Posted on Tuesday, 02 November, 2004 - 17:50: |    |

Robert.

I will let you work out why it is vital to deal with the nut excersize, you realy must use common sence on that. |

Robert Chapman

Prolific User

Username: shadow

Post Number: 100

Registered: 5-2003

| | Posted on Tuesday, 02 November, 2004 - 19:46: |    |

No no Pat, please stop it my sides are splitting.

A jokes a joke but we have tumbled you now,you took it to far with the pitman arm nut thing,that gave you away,it was just to silly to be true.

When I think back to all those other outrageous statemets you have made and ridiculous arguments you have put forward and all the time you were just winding us up.I should have known you could not be serious,your good for a laugh I will give you that.

Well you have had your laugh,I will not be taken in by anything you have to say from now on.

Have you heard the one about the monkey and the MOT tester they sent to the moon. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 41

Registered: 9-2004

| | Posted on Tuesday, 02 November, 2004 - 20:17: |    |

Robert it has been your manner and statements with alarmist posts and now you have realized how wrong you are and for all to see.

All you can do is show your true colours and try to laugh it off.

Sad on you. |

Robert Chapman

Grand Master

Username: shadow

Post Number: 101

Registered: 5-2003

| | Posted on Tuesday, 02 November, 2004 - 21:20: |    |

Pat,

I have told you,you have been sprung,you won't get me going any more,what a card you are.

I should have twigged when you came out with that "incorrect facts" thing, how did you keep a straight face whilst posting that? .

And the best one was the way you wrote your post's,making out you were drunk! BRILLIANT

Can I take it from this post you have heard the one about the MOT tester and the monkey then?

Say good night Pat, good night Pat. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 42

Registered: 9-2004

| | Posted on Tuesday, 02 November, 2004 - 23:11: |    |

Robert.Good night to you.

And now good morning to you.

I am sure i will now get you going to let us all have your program of registerd percentage failures so we all have some idea of the problem with the cars you have dealings wih of course you will find a great diference once you deal with the stated items above that i have provided you. |

John Dare

Unregistered guest

Posted From: 144.138.194.57

| | Posted on Tuesday, 02 November, 2004 - 19:47: |    |

No disrespect nor offence is intended toward our U.S cousins when I say that, following many visits to that great country, I have noted far more sub standard (neglected and/or abused) condition, Silver Shadows than here in Australia. I have of course, taken into account, the population difference in the course of those observations (during which time I HAVE seen some examples from good to very good, to spectacular!) and remain mindful of comments made by well known (and "R-R" AUTHORITIVE) Englishmen, who, upon visiting Australia, have remarked upon the GENERAL higher standard of cars to be found here. Perhaps it is because "our"(VERY expensive!)cars here are somewhat more respected, if not revered (and serviced/maintained accordingly!) that many have been EXPORTED, most notably, BACK to ENGLAND!.I will refrain from any comment on the "quality" of recent(previous 10 years) U.K Shadow imports (ex Luton or Peckham?) as frequently orchestrated by "fast buck" mechants in pursuit of a quick dollar. During my discussions in recent years with several U.S based R-R specialists regarding pitman arms, NONE have reported fractured arms in pre SS11 (LEFT drive) vehicles, despite the fact that many such cars appear to have been simply "driven", with token (if any) regard to service and maintenence. NO comments were made re the periodic re-torqueing of nuts; cyl.head/exh.manif.nuts excepted. With rates in excess of US$100 per hour we may begin to understand how that situation may have evolved over the years. Now, the $64K question IS.. Why is there no (or IF any, then virtually insignifigant) failure in LHD pitman arms which are PRESUMABLY (point open to debate) a "mirror" image (reverse orientation) of the "sister" RHD arm. I have already put this tantalizing question to our very own "world authority/expert", but sadly, as with most self appointed experts I have encountered upon the tortuous highway of life, the silence has been deafening. Perhaps the proposed metallurgical investigation (by a suitably qualified PROFESSIONAL!) might serve to provide the elusive answer. And NO.. its NOT the perceived "poor" condition of Australian roads, since the majority of R-Rs in this country, proceed quiety upon roads generally similar to those found in the USA. And of course, do so without a dreadful caravan in tow.

I would be VERY VERY appreciative if our overseas contributors could confirm that LHD Shadows have not experienced this problem or if the problem was confined to the original arms only. Thanks in anticipation David

(Message edited by david_gore on November 03, 2004)

(Message approved by david_gore) |

John Dare

Unregistered guest

Posted From: 144.138.194.114

| | Posted on Tuesday, 02 November, 2004 - 07:58: |    |

I find the post of Nov.2nd (P.Lockyer) both confusing and contradictory. Although it is conceded that there was/is a weakness in the original design (hence the factory issue of a stronger arm)it is implied that, as there was no "official" (read EMBARRASSING!) recall, the issue (instant steering failure!) is NOT a SERIOUS issue. Then the poster optimistically declares his "hope" that we will take this (his!) "advice" seriously?. He goes on to suggest that even after fitment of the stronger, R-R modified arm, problems may still recur on the taper unless "other"(?)faults are addressed. I know of MANY cars (my own included) which have had the modified arm fitted and NONE of them have failed nor have they required "special" attention ( periodic re-torqueing) nor have their front suspension/steering components needed any more than normal basic servicing of the kind routinely performed by a first year apprentice or even a weekend D.I.Yer. If the poster has a recurring problem with his own taper, then perhaps further inspection is warranted to identify the unfortunate cause/s thereof.

(Message approved by david_gore) |

David Gore

Moderator

Username: david_gore

Post Number: 326

Registered: 4-2003

| | Posted on Wednesday, 03 November, 2004 - 08:56: |    |

Hi Richard,

Sorry for delay in responding to your post above as I have been away - thanks for your offer however the tack welding "get-you-home-safely" repair will have destroyed the evidence I will be looking for to determine the cause of the cracking - I am not going to pre-empt this investigation however the are at least two plausible explanations for the problem; one is obviously fatigue, the other is ductile/brittle transition temperature associated with other service factors.

I am going to need all the help I can get on this problem from owners of affected cars with information on the location, use, driving habits, climatic conditions etc once the possible causes are identified. For example, Robert has mentioned recent failures in Melbourne yet I am not aware of any failures in Sydney [I have yet to check this out more thoroughly].

MY MAJOR CONCERN IS THE REPORTED FAILURE OF THE MODIFIED ARMS NOT THE ORIGINAL ARMS. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 414

Registered: 4-2003

| | Posted on Wednesday, 03 November, 2004 - 17:43: |    |

David,

From a selfish point of view, I too am more interested now in the reliability of the new type of Pitman arm as, like John's, ours has been replaced.

On location, our car has spent its years roughly half-half Sydney and Canberra. You could call it a Sydney car. It was delivered new in Sydney by York Motors and always serviced by them until I got my hands on it around 1985 when we considered it old enough for DIY. Always garaged, the temperatures have been mild with the exception of trips to the Snowy Mountains or the odd frosty morning outside. Mind you, it gets pretty hot down at the steering box when driving.

When I ordered the new part, the Sydney agent didn't need to look up the part numbers: Tom was rather familiar with this failure. That suggests that there have been rather a few failures in Sydney. Do you think that a few Kelvins temperature difference between cities would make much of a difference ?

I'll hold off on sending you the Pitman arm. I'm sure that Robert Chapman can provide what is most useful from his collection of trophies. As he has done a few and probably carries spares, he probably never needed to tack weld one to manoevre a car into a corner waiting for spares.

RT. |

Phil Sproston

Unregistered guest

Posted From: 203.206.48.94

| | Posted on Wednesday, 03 November, 2004 - 20:48: |    |

Pat, re. your post on 2-11-04, on your list you missed mentioning the Steering idler box. If it isn't filled with oil it can cause problems from the road vibration, which affects the Pitman arm. In almost every idler box I have checked there has been little to no oil remaining.

(Message approved by david_gore) |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 43

Registered: 9-2004

| | Posted on Thursday, 04 November, 2004 - 23:47: |    |

Phil,spot on i had forgot that one and maybe some other points as i was rather quick to reply on the alarmist posting. |

Robert Chapman

Grand Master

Username: shadow

Post Number: 102

Registered: 5-2003

| | Posted on Friday, 05 November, 2004 - 10:56: |    |

Phil.

Are you saying that an ineffective steering damper will CAUSE the pitman arm to break?

Or are you saying an ineffective steering damper will add extra stress to an already CRACKED pitman arm, as would all shock loads feed back into the steering.

|

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 44

Registered: 9-2004

| | Posted on Friday, 05 November, 2004 - 17:32: |    |

Robert Chapman.

still cannot understand, except the route causes and correct them on your cars.

The cracks you are finding relate direcly to your failure to except the above.

What is your percentage of failures we are all still waiting to help you on this matter. |

John Dare

Unregistered guest

Posted From: 144.138.194.153

| | Posted on Friday, 05 November, 2004 - 08:14: |    |

Some of the many cars which I have owned in the past, including some in my current possession, have steering "dampers" and some do not. Those without such dampers have NOT suffered abnormal tyre wear let alone ANY failure of a steering related component, especially not a Pitman arm. For obvious reasons such CRITICAL components are USUALLY "overdesigned" in the FIRST instance, and then attached to the steering box shaft in a "fail safe" manner; splined/tapered/securing nut etc. The irrefutable record CLEARLY indicates that the original Shadow pitman arms were far from "OVERdesigned", hence the later issue of the redesigned, stronger unit. I am unaware of any failures of the later modified type ,irrespective of whether or not the car/s were (or are) fitted with idler/damper boxes.

(Message approved by david_gore) |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 52

Registered: 9-2004

| | Posted on Saturday, 13 November, 2004 - 06:17: |    |

No confirmed breakages of arms i thought there would have been according to the alarmist posting,but alas it seems that the many cars apart from the Melbourne Specialist are maintained to a satisfactory standard with the above points delt with.

|

John Dare

Unregistered guest

Posted From: 144.138.194.195

| | Posted on Saturday, 13 November, 2004 - 07:39: |    |

Patrick. If you ever do favour us with your presence and worldy knowledge, you will discover that there are places and locations in Australia, OTHER than Melbourne (SYDNEY for example) where Shadow Pitman arms have failed. Different owners,different(traffic)environmemt/operating regimes and(obviously)different service points and facilities. How say you now?

(Message approved by david_gore) |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 54

Registered: 9-2004

| | Posted on Saturday, 13 November, 2004 - 09:10: |    |

J.G.Dare.

Of confirmed horrible letter fame.

As others and i have stated before you are no engineer,just a professional bore with words. |

John Dare

Unregistered guest

Posted From: 144.138.194.234

| | Posted on Saturday, 13 November, 2004 - 09:52: |    |

Thank you Patrick. Thats WHY we NEED you here (in person) to SHOW (rather than simply "tell")us mere mortals HOW to perform various "R-R" repair/maintenence procedures. All tools, equipment and parts can be made available for the grand event which I expect will be a most memorable experience not easily forgotten. All you need do is let us know when you are coming. Any time soon?

(Message approved by david_gore) |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 60

Registered: 9-2004

| | Posted on Tuesday, 16 November, 2004 - 05:50: |    |

J.G.Dare.

Of confirmed horrible letter fame.

More of your Rubbish.

|

John Dare

Unregistered guest

Posted From: 144.138.194.249

| | Posted on Tuesday, 16 November, 2004 - 10:53: |    |

It has been asserted by the worldy and wise, that the widely documented failure of Shadow (Series 1) pitman arms is attributable (in some way) to neglect, poor, or sub standard "maintenence" etc. I wonder why there has been no recorded (frequent) failure of say, Mark V1/"R"type/Dawn or "S" series cars Pitman arms, especially given that those cars are so much OLDER, have had many owners and therefore widely varying service personel attending to them, neither of whom may have regularly observed and maintained the highest service/maintenence standards.

(Message approved by david_gore) |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 436

Registered: 4-2003

| | Posted on Wednesday, 17 November, 2004 - 09:53: |    |

John,

At the risk of rebuke, you know my views. A Pitman arm, or its side arm lever cousin on a Mk VI, has no excuse whatsoever for any sort of failure ever. Nor does a final drive or rear suspension crossmember.

The fact that RHD Shadow Pitman arms and all Shadow final drive crossmembers fall off at random is astonishing and has nothing to do with maintenance, abuse or bumps in the night.

I don't care if they mostly all break at just 10 km/h, they are still critical safety-related failures. It is not a cost issue: we all want to stop the risk of catastrophe to ourselves and our families.

My yet-again leaky steering rack, after replacing it 9 months ago, will cost me a grand or so too, but at least the damage so far is just a letter from the police complaining about oil stains on the carpark. Fines may follow. With standard maintenance, I can check the steering fluid for a very slow leak, but not metal fatigue.

RT. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 64

Registered: 9-2004

| | Posted on Wednesday, 17 November, 2004 - 17:42: |    |

Richard,i may be able to hopefuly help on the leaking rack.

Is there a topic on racks some where as i think we ought to keep this one to the pitman arm.

In haste PL. |

Robert Chapman

Grand Master

Username: shadow

Post Number: 105

Registered: 5-2003

| | Posted on Wednesday, 17 November, 2004 - 19:32: |    |

Richard,

It would seem that you also, have failed to "grasp the route cause" of these failures (according to pat).

But I am sure you are very pleased and greatful that help is on the way regarding your leaking rack,well I think thats what he said.

|

Robert Chapman

Grand Master

Username: shadow

Post Number: 106

Registered: 5-2003

| | Posted on Wednesday, 17 November, 2004 - 20:04: |    |

Richard ,

At the risk of being called alarmist,what is your opinion on changing the two centre rack bolts,or at least inspecting very closely for necking,when removing or refitting racks.

I have found quite often that they have been over tightened(not using torque wrench)and are visibly stretched in the threads.

I would be interested,doe's your rack leak from the top pinion seal or ram?. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 437

Registered: 4-2003

| | Posted on Wednesday, 17 November, 2004 - 21:27: |    |

Robert,

I'll switch the rack topic to Silver Spirit etc. |

John Dare

Unregistered guest

Posted From: 144.138.194.241

| | Posted on Wednesday, 17 November, 2004 - 10:40: |    |

Thank you Richard. I need to clarify beyond any doubt that it was NOT I (nor you, as I recall) who had vehemently suggested that certain Shadow problems (particularly Series 1 pitman arm failures)were the result of operator abuse, sub standard or questionable maintenence procedures such as "failing" to re-torque pitman arm retaining nuts at periodic intervals. If either of those factors were proven to be causative, then not unreasonably, one would have expected similar Pitman arm failures (incl. frequency of)in earlier "R-R/B" vehicles, due to their (older) age, during which time they would have been exposed to different owners AND a wide variety of service/maintenence regimes. To date, I remain unaware of any such failures, and as you further indicate, none are expected. Nor should they be.

(Message approved by david_gore) |

David Gore

Moderator

Username: david_gore

Post Number: 328

Registered: 4-2003

| | Posted on Thursday, 18 November, 2004 - 10:09: |    |

Hi Richard,

re testing Pitman arms; I suspect you would be aware that you can dye-penetrant test [either visible dye or UV fluorescer] these for incipient cracking however it is essential to remove them from the vehicle and thoroughly degrease/clean the arm boss before testing.

If you would like more information; please contact me direct. |

John Dare

Unregistered guest

Posted From: 144.138.194.15

| | Posted on Monday, 22 November, 2004 - 13:35: |    |

During the discussion under this thread, it was implied that Shadow 1 Pitman arms had failed due (in part)to "improper maintenence"; in particular, the failure to periodically re-torque the Pitman arm retaining nut. I am unaware of this practice and have NEVER heard, let alone READ (in ANY publication/s; mnfrs. or independent authority)of this service requirement. I suspect that is due, in part,to the potential,however remote, for auto. servicemen (somewhere) to either under tighten, or worse, OVERtighten the nut, the latter tending to drive the pitman arm "hub" further onto the tapered steering shaft spline with inevitable consequences. That observation ASIDE, I ask WHY is it that IF the suggested procedure (re-torqueing) has been "ignored", thereby contributing to Shadow 1 arm failures, WHY is it that Mk6/Dawn/R-type and "S" series pitman arms have not ALSO failed, given that, to my knowledge, such cars have NOT (according to R-R) required periodic re-torqueing, NOR have owners done so of their own volition in deference to pre-emptive and of course, "correct" maintenence.

(Message approved by david_gore) |

Robert Chapman

Grand Master

Username: shadow

Post Number: 116

Registered: 5-2003

| | Posted on Monday, 22 November, 2004 - 21:31: |    |

Hi David,

It is the dye penetrant method we are using on all cars passing through the workshop, as I have told Richard we have changed 5 in the last 3 years(not including the latest 3).

Three were detected cracked by testing on car and 2 were cars brought in(with arms completely broken) previously unknown to us.

We test them in position and if in any doubt removed,both free and bolted up to a dummy shaft.

I am sure there has never been any failure of the replacement arms,and when the new type arm is seen,it is obvious why.

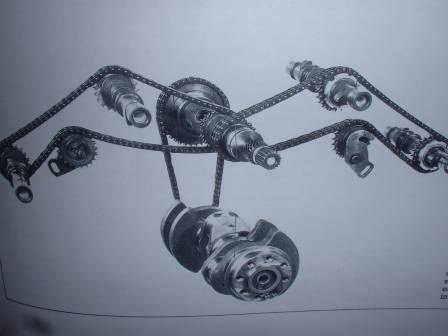

Would it be possible to post the photo I sent showing the two different arms. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 451

Registered: 4-2003

| | Posted on Monday, 22 November, 2004 - 22:29: |    |

Robert,

I am relieved to hear that you cite no cases of failed new-type Pitman arms.

Posting the pictures would be very useful. Viewers can then identify whether their Pitman arm is a new safer type or not. The new type is indeed quite noticeably different. We have spent the cash on a new one already, so cannor benefit.

I would go so far as to urge all owners with the original type to replace it immediately test or not as it's clearly a time bomb. If people pool together, pressure could be brought on Crewe to give a very reasonable price for a large quantity. It's no use pretending that this issue will fade away, so why not bite the bullet ? The labour involved is not at all great, and an early replacement will save time, cost and convenience, let alone the safety issue.

When ours broke some years ago, my father was doing a U-Turn which became almost a loop. The shock of losing control can lead to any imaginable reaction. Thank goodness there was no traffic. Usually on doing a U-Turn you hurry off to avoid the following traffic. Even if a U-Turn is at just 5 km/h a serious accident can easily result as the traffic collides with your car.

Please, no one tell me this is not a safety matter because failure is almost always at low speed. I would not enjoy losing my steering at just 10km/h on a hairpin bend, and plunging down a cliff. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 452

Registered: 4-2003

| | Posted on Monday, 22 November, 2004 - 22:37: |    |

For David Gore:

I have enquired about LHD Pitman arms in Europe and the US, and have no report of a Pitman arm failure on a LHD car. I dare not ask Crewe though. The main dealer here in Zürich has confirmed only RHD failures, and quite a few at that.

That doesn't mean that they don't fail, but it does seem to be a RHD thing. Maybe General Motors / Saginaw put too little effort into the conversion of their overall design to RHD.

Next time I'm near a LHD Shadow I'll poke the camera underneath and post the picture.

RT. |

David Gore

Moderator

Username: david_gore

Post Number: 331

Registered: 4-2003

| | Posted on Tuesday, 23 November, 2004 - 09:34: |    |

Hi Everyone,

Have attached photo below and thanks to Robert for sharing this with us - note the significant increase in the thickness of the boss. My thoughts on the failure are as below:-

1. The undisputed fact that failures have only occurred on RHD vehicles suggest the cause of the problem may not be under-design but related to stress loadings generated by the linkages in the RHD system. If there was an inherent design fault; failures should have occurred on both LHD and RHD vehicles.

2. The location of what appears to be a classic reverse-cycle fatigue crack on one shoulder of the boss only indicates non-uniform stress loadings from linkage movements/suspension loadings - what would be interesting would be to know whether the stress is coming from LH or RH turns. If the loadings were equal from each type of turn; I would have expected cracking to be evident on each shoulder of the boss with ultimate failure from the side subject to the greatest number of heavily loaded turns [eg turning downhill into a home driveway where all the loads are on the outside wheel].

3. With due respect to Pat's experience and knowledge; I am yet to be convinced that this type of failure can be prevented by regular retorqueing of the arm retaining nut - this practice is desirable to prevent premature wear of the splines but I can see no metallurgical benefit from this practice which would neutralise the cause of the fatigue cracks observed. The usual solution to fatigue cracks of this nature is to reduce the generation of tensile stresses at the metal surface and to eliminate any stress concentrators such as notches, abrupt changes in section and/or machining marks. Tensile stresses may be reduced by increasing the metal thickness as evident in the modified arm, by inducing compressive stresses in the surface layers by case/flame hardening or by shot peening. Of course, the best solution is to look at the overall design of the system to reduce overall stress loadings wherever possible.

4. With regard to Richard's comment on conversion of the Saginaw unit to RHD - my view is that the unit would have been designed to withstand equal loadings from either extremity of component movement. the one-sided incidence of this failure suggests very emphatically to me that the problem is related to the design/action of the RHD linkages.

Hope this is of interest and will generate some discussion from our practical contributors who have actually worked on this problem - I have not had this experience and qualify my comments accordingly.

Robert's photo of cracked original arm and factory modified replacement

|

David Gore

Moderator

Username: david_gore

Post Number: 332

Registered: 4-2003

| | Posted on Tuesday, 23 November, 2004 - 10:18: |    |

Further to the above photo; have enlarged cracked arm so failure is easier to see for your benefit.

Location of Crack

Close-up of Crack

|

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 90

Registered: 9-2004

| | Posted on Tuesday, 23 November, 2004 - 17:38: |    |

Thank you Robert for the letting us have a look at the pictures of the pitman arm and David for his findings.

I agree also it is caused by load stress Fatigue.

However as i have stated from the start brought about by the loadings of the steering through the above failings of stated points not being carried out.

As the for the torqueing of the nut excersize i will let you all work on that for the time being.

As i have said there is a weakness in the arm but only brought about by other underlying faults.

I will also tell of other sudden failings with the car and cars in general but only when it is brought up in a topic as i do not want appear an alarmist.

|

Robert Chapman

Grand Master

Username: shadow

Post Number: 117

Registered: 5-2003

| | Posted on Tuesday, 23 November, 2004 - 21:20: |    |

Hi Richard,

In answer to your post of 22/11 /04,I agree with your idea of Crewe supplying the arms at a much more reasonable price if not free, in the light of the obvious fault in this part.

And the ideal situation would be to replace them all before anymore fail.

In the mean time I shall carry on with the crack testing and if by doing so and bringing the fault to the attention of the owners I am labelled ALARMIST so be it .

I will be happy to bear that cross as I have a professional duty of care responsibility. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 92

Registered: 9-2004

| | Posted on Wednesday, 24 November, 2004 - 05:22: |    |

David have had time to take a closer look at the above enlarged photo.

I am more alarmed than ever as it has confirmed my above statements.

The picture not only shows the fracture but the cause of it.

The movment on the splines and over a long period

somthing that would be detected in the vehicle servicing maintenence checks before it ever got in that state.

As i have said and i am most surprised that the torque nut excersise by other folk has not been excepted and taken up with a cunning but simple checking procedure.

Regarding the fitment of a modified shaft,i cannot believe that there has been no mention of the damaged rocking shaft splines or do they not wear.

most of the route causes i have stated above in previous posts.

Regarding the LHD RHD shafts are they both the same part numbers.

|

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 453

Registered: 4-2003

| | Posted on Wednesday, 24 November, 2004 - 06:11: |    |

The LHD and RHD side arm levers (Pitman Arms) are not the same.

For example, late chassis SSI have UR18370 (RHD and UR18371 (LHD) originally, secretely superseded by something like UR22990 and UR22991.

Under a failure condition, the weak side is clearly the arm/lever itself, and after checking this in as many cases as possible, the steering box output spline has never known to be worn or damaged after a sadly normal Pitman arm failure. The failed one in David's picture has probably been lying around and corroded a bit as well.

The substantially beefed-up nature of the revised Pitman arms is encouraging.

RT. |

Patrick Lockyer.

Prolific User

Username: pat_lockyer

Post Number: 94

Registered: 9-2004

| | Posted on Wednesday, 24 November, 2004 - 06:20: |    |

Crums Richard that was quick thanks.

However it has opened another thought and closed one.

Back to the Glenfiddich! |

David Gore

Moderator

Username: david_gore

Post Number: 333

Registered: 4-2003

| | Posted on Wednesday, 24 November, 2004 - 08:20: |    |

Pat & Richard,

Thanks for your observations - further to my original comments and WITHOUT the benefit of examining the cracked arm; I am reasonably confident the fatigue crack has initiated on the surface of the boss shoulder and progressed inwards towards the splines. You will note there is a "crease" mark from the forging process on the shoulder and my suspicions are that this has acted as a stress concentrator to initiate the crack. For this reason; I still have to be convinced that retention practice will definitely control this mode of failure Pat, please contact me direct if you wish to discuss this in more detail with me privately

WHAT STILL PERPLEXES ME IS THE FACT THAT THIS FAILURE ONLY OCCURS ON RHD VEHICLES. |

John Dare

Unregistered guest

Posted From: 144.138.194.56

| | Posted on Tuesday, 23 November, 2004 - 11:12: |    |

At last what appears to be the definitive answer!. And someone once said "SIZE doesnt matter"?. LOOK at the DIFFERENCE in boss/hub size DIAMETER of the two Pitman arms as clearly depicted!. I extend my appreciation, especially to those who contributed to this vexed topic, doing so at what was clearly a professional level. At least the more astute among us may now relax, knowing that we dont have to adjust or otherwise interfere with our nuts, even though some may,for whatever dubious reason/s, continue to do so.

(Message approved by david_gore) |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 101

Registered: 9-2004

| | Posted on Thursday, 25 November, 2004 - 13:40: |    |

J.G.Dare.

More rambling rubbish.

(Message edited by david_gore on November 25, 2004) |

John Dickinson

Frequent User

Username: au2018

Post Number: 14

Registered: 11-2003

| | Posted on Saturday, 27 November, 2004 - 10:19: |    |

Hi to all,

Being a recent convert to the world of motor cars (after motorcycle ownership for most of my adult life) I find technical discussion such as this thread quite fascinating viz. Pitman Arm Failure.

Could someone please help me here? When discussing a Pitman Arm which component in the Silver Shadow steering mechanism are you actually referring to? The R-R CD manuals indicate the cross beam member, idler lever, pendulum lever and track rods.

Thanks for any help. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 458

Registered: 4-2003

| | Posted on Saturday, 27 November, 2004 - 20:31: |    |

Pitman Arm is US/Oz for pendulum lever, mate. |

Bill Coburn

Grand Master

Username: bill_coburn

Post Number: 282

Registered: 4-2003

| | Posted on Saturday, 27 November, 2004 - 23:21: |    |

an interesting question John. I have often wondered who was Pitman other than the man who invented the most used shorthand. But presumably he did something for the 'pendulum lever' and attached his name to it. The 'pendulum arm' descriptive is simple in that the original manual steering boxes had horizontal output shafts on which an arm was attached which swung forward and backward pushing a 'drag link' that in turn swivelled the wheels. Poor Mr Pitman - lost in time but he would probably be horrified that his creation was so poorly executed my the manufacturers of the 'Best Car in the World'! |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 459

Registered: 4-2003

| | Posted on Saturday, 27 November, 2004 - 23:43: |    |

Bill,

On Mk VI etc it is named Pendulum Lever in the literature, with the fore-aft drag link ("side steering tube") as you describe.

Other names are side arm lever, drop arm lever, and pendulum arm as you point out.

Trust we Aussies to make up our own component names. I challenge you to order a circlip in German though. Last week I had to buy some circlip pliers in French. That was a challenge I can assure you. |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 460

Registered: 4-2003

| | Posted on Sunday, 28 November, 2004 - 03:27: |    |

Just a titbit of information.

All Silver Shadows have the same idler lever, although of course LHD and RHD are mirrored, as are the Pitman arms. The idler damper was virtually unchanged through the series too. This is despite the deletion of the subframe Panhard rod along the way (I think that diasppeared when the compliant suspension came along), and the front levelling disappearing at Chassis 12586.

All idler arms:

RHD: UR14702

LHD: UR14703

The Pitman arm changed when the last change to the steering box was introduced at chassis 11215. There were quite a few cars with the earlier box produced after 11215, presumably a light-steering option.

Pitman arm number until chassis 11214:

RHD: UR13344

LHD: UR13345

From chassis 11215, most were

RHD: UR17106

LHD: UR17105

There is no apparent correlation between compliant suspension and Pitman arm failures it seems: our T has pre-compliant suspension and had the later Pitman arm until it broke, and I know of several compliant-suspension cars which have suffered failures too.

It would be interesting to know if any earlier UR13344 Pitman arms have failed. Also, perhaps Robert could let us know the present replacement part number, and whether the UR13344 and UR17106 have a common replacement.

RT. |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 104

Registered: 9-2004

| | Posted on Sunday, 28 November, 2004 - 03:45: |    |

Ok so here "Uk" we call it all three,but most common drop arm.

Anyway back to the failings of only Rhd vehicles and in my opinion brought about by the loading of the steering brought about by the stated above on the early shaft.

Now why just Rhd after the 10 year design and all testing before the launch of the car,surely if it

was a problem it would have shown up or would it.

Could the later deletion of the Panhard rod fitted to the sub frame of the early car be the cause.

This clever little chap was used to stabilise the

the front sub frame that as we know is mounted on flexible mounts to stop vibrations [noise],dificult due to the low frequencies as the whole subframe will have a resonant at one of its natural mounting frequencies confirmed by by slight shake under controlled testing.

Now why rare failings of rhd cars,i believe it is caused by "Directional torque" within the subframe,with the engine and gearbox mounted within.

Was that the clever design engineers reason of the panhard rod,if so would be confirmed by no failings of early cars arms.

They sure would have done a recall if there was!

If it is so then the modified arm will not break but will fail on the splines over a longer period of time,more so with the the above service maintenance problems pressent and the nut torque excersise not carried out. |

John Dickinson

Frequent User

Username: au2018

Post Number: 15

Registered: 11-2003

| | Posted on Sunday, 28 November, 2004 - 10:26: |    |

Thank you Messrs Treacy and Coburn. I appreciate your assistance in explaining the diverse nomenclature of the humble Pitman arm. |

John Dare

Unregistered guest

Posted From: 144.139.15.141

| | Posted on Saturday, 27 November, 2004 - 16:00: |    |

Thank you John. In the "R-R" S/Shadow (Series ONE!) W/shop manual/parts book, it is referred to as the Pendulum lever. Like almost EVERY vehicle on the road (commercial or passenger type) such arms, variously referred to as Drop,Pitman or Steering arms, are fitted (for obvious reasons) by a "double indemnity/fail-safe" method of being mounted on a tapered spline, thereafter secured with a nut torqued to a very high tension. Said nut therefore (usually) has few threads, being intended to be torqued (upon initial installation (at factory and/or after removal/replacement of steering box) AND THEN LEFT ALONE. Such nuts are NOT "multiple cycle" nuts to be loosened and tightened like simple "Marmite" lids/Scottish Malt caps or other commonly found screw/threaded type fasteners.

(Message approved by david_gore) |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 112

Registered: 9-2004

| | Posted on Tuesday, 30 November, 2004 - 05:45: |    |

J.G.Dare.

Read the posting above, EVERY TWO YEARS.

and then a proceedure that you and others have failed to work out.

(Message edited by david_gore on November 30, 2004) |

John Dare

Unregistered guest

Posted From: 144.138.194.90

| | Posted on Tuesday, 30 November, 2004 - 07:34: |    |

I have yet to read in ANY automotive book or mnfrs. workshop publication, ANY reference (express or implied) regarding the "two year" interval or indeed ANY interval, requiring the re-torqueing of Pitman arm retaining nuts. Perhaps those who continue to stridently advance this notion could quote a supporting reference from some (ANY) recognized auto. text book which they read during their studies whilst in pursuit of their automotive related qualifications. At that time it would be opportune for them to finally declare the precise nature of said qualifications, in order that some credibility might be established to support that which they continue to espouse.

(Message approved by david_gore) |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 122

Registered: 9-2004

| | Posted on Wednesday, 01 December, 2004 - 07:19: |    |

J.G.Dare.

As i have said before,years of practicle experience not always learnt from a book.

As you cannot except that,i have no satisfaction to tell you and then be ridiculed by you.

Regarding the the posting on the 28th it would be interesting if there was some response to maybe an interesting subject.

PITMAN ARM FAILURE.

|

John Dare

Unregistered guest

Posted From: 144.138.194.6

| | Posted on Wednesday, 01 December, 2004 - 11:37: |    |

Thank you Patrick, for yours of 1/12 (8-19am) where you appear to imply that your technical knowledge has been aquired by practical experience. Would you please advise details of your experience and qualifications.

(Message edited by david_gore on December 01, 2004)

(Message approved by david_gore) |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 126

Registered: 9-2004

| | Posted on Wednesday, 01 December, 2004 - 17:47: |    |

Pitman Arm failings is the topic here.

Are we now to have a qualifications topic for all who use this forum!

I will be pleased to do so if that is the case as i do not need to SWANK with mine at present. |

John Dare

Unregistered guest

Posted From: 144.138.194.131

| | Posted on Wednesday, 01 December, 2004 - 19:02: |    |

Thank you Patrick. Yes, the topic is S/Shadow (series 1) Pitman arms;failure of. From the outset you have vigorously espoused the theory that said failure is the result of lack of maintenence, primarily, the failure to periodically re-torque the pitman arm retaining nut. You continued assertions in that regard (incl.ref.to other alleged causes) blatantly defy compelling evidence from qualified professional automotive engineers,technicians and even metallurgists!. Repetitious comment deleted. For the record; the metallurgist is keeping an open mind on this as there are possible maintenance-related causes for the problem and I have not seen any evidence so far to eliminate this possibility

(Message edited by david_gore on December 02, 2004)

(Message approved by david_gore) |

whunter

Grand Master

Username: whunter

Post Number: 111

Registered: 10-2003

| | Posted on Thursday, 02 December, 2004 - 12:52: |    |

I should like to know at least some of your credentials, since you are giving advice on safety issues, steering and hydraulic system = brakes.

We make no issue of skill level.

However; people have a right to know at least some credentials possessed by the person telling them to spend money on this or that repair.

Evasion is not acceptable...

If you are a retired Rolls-Royce / Bentley engineer or technician, possibly a research person from CREWE, a mechanic working at the corner garage, even an owner who works on their own cars.

If privacy is a concern, send the information to David Gore, he may winnow it down to a brief statement and e-mail the registered forum members.

Please make a clean breast of it; and close the question…

Have a wonderful day. |

William H. Trovinger II

Grand Master

Username: bill_trovinger

Post Number: 176

Registered: 8-2003

| | Posted on Thursday, 02 December, 2004 - 14:35: |    |

Whunter;

I do not know if I agree with you or not. As showing ones credentials has never been a prerequisite to posting, let alone as you state “a right to know”. I think each owner can (and should) take comments made by other (whether on this site or any of the other sites) with at least a grain of salt, unless that person is forthright with their background.

However, if one where wishing to push this issue than I believe you should also include Mr. Dare as I do not recall a posting where he as spelled out his qualification either. After all fair is fair and Mr. Dare has made many a claims on this and other forums.

With that said and in light of the seriousness of this issue (and others) I would like to ask all contributors to keep comments to the issue of the thread and leave personalities out of the debate.

Best regards,

Bill

Moderator's Comment:

Thank you Bill as I am sure your views match those of the "silent majority" who visit this site. I have also addressed this problem in my comments to today's posts in the topic "Static V Dynamic Compression".

All posts regardless of whether they come from registered users or guests are now being edited without fear or favour to remove extraneous comments that are not relevant to the topic under discussion.

(Message edited by david_gore on December 02, 2004) |

John Dare

Unregistered guest

Posted From: 144.138.194.200

| | Posted on Thursday, 02 December, 2004 - 12:17: |    |

Thank you D.Gore;your addendum of 2/12. On 30/10, P.Locker opened this particular thread and implied in his opening para.that poor maintenence was a causative factor;at para.1 specifically referring to the pitman arm retaining nut, suggesting that it should be, "released and retorqued every couple(?) of years or so to 200lb.ft"(sic). On 2/12, you indicated that you are keeping an open mind on maintenence related causes and that you have not seen any evidence so far to eliminate this possibility. Apart from evidence previously supplied from qualified and long experienced engineers and auto. technicians, kindly allow me to sumbit in evidence (hard copy available) a response received this day from a U.S based MANUFACTURER of Pitman Arms AND retaning Nut "kits" (washer/nut/pin etc.) who supply (OEM) major auto mnfrs.including that vehicle immortalized by a state Governor who has a large desk in Sacramento. The response unequivocally addresses the PRINCIPAL issue so tirelessly (AND authoritively) advanced to date, and I quote verbatim; "I have read the military maintenence manuals for many vehicles and have never heard of this being on a maintenence list for any reason". He added, "I would recommend against this retorquing procedure. At best it helps nothing and at worst it will cause wear and damage to the parts". I have nothing further (Well,not until additional and AUTHORITIVE supporting evidence is received,receipt of which is pending at this time)

Moderator's Comment:

John, in relation to my comment of today relating to an open mind; I was not specifically referring to the Pitman arm retaining nut but to other maintenance practices/neglect that could be contributing to the fact that failure has only occurred on RHD vehicles. A number of possible causes have been suggested to me privately and these will be assessed from a metallurgical perspective in the light of any information that becomes available.

(Message edited by david_gore on December 02, 2004)

(Message approved by david_gore) |

John Dare

Unregistered guest

Posted From: 144.138.194.14

| | Posted on Thursday, 02 December, 2004 - 20:51: |    |

Bill Trovinger. Thank you for your recent response in reply to your compatriot W.Hunter, wherein you suggest that contributors (to forums) are not obliged to reveal their qualifications, let alone assume a "right to know". As I recall, it was YOUR goodself who very much suggested YOUR "right to KNOW" the details of the analysis of "363" fluid, being an analysis, sought by, paid for, and held by me. It was not available to you then, nor is it ever likely to be, despite your moral posturings (at the time) about the "obligations" etc.,of "helping" fellow "R-R" owners etc. You are correct in that I have not volunteered my "qualifications" nor do I feel obliged to do so.

I did raise, on your fine U.S forum (as I did on this forum) the subject of "GM" engine conversions whereby I was attacked by all and sundry from Anchorage to Key West, almost expecting a dark suit to quietly arrive from Langley. My most memorable opponent was Douglas R, for whom I hold sincere respect, given his extensive knowledge, and he likewise, was gracious enough to concede (at the conclusion of "hostilities") that I "argued my point well" . As you may observe, I survived a phalanx of fire from your countrymen, recalling that only ONE (Mollich) or perhaps two (?) DARED to volunteer any supportive commentary, perhaps being ruefully aware that "GM"conversions (upon "R-R"s) were indeed, FIRST PERFORMED IN THE USA!.

Moderator's Comment:

John, after much soul searching I have had to delete your questions relating to the US forum as these are internal policy matters relating to moderators and their duties which are determined and applied by the US RROC at their absolute discretion.

(Message edited by david_gore on December 03, 2004)

(Message approved by david_gore) |

whunter

Grand Master

Username: whunter

Post Number: 112

Registered: 10-2003

| | Posted on Friday, 03 December, 2004 - 16:26: |    |

Thank you David, for a difficult job (moderator), well done.

I shall be brief.

What testing are the samples being subjected to?

This issue has me concerned for several friends.

This may be my last post for a while, due to holidays and other real world concerns.

I will try to follow threads and keep up.

Have a great day.

|

David Gore

Moderator

Username: david_gore

Post Number: 341

Registered: 4-2003

| | Posted on Saturday, 04 December, 2004 - 08:46: |    |

Hi everyone,

As I originally stated, my only concern was the impression I received that failures of the modified arms had started to be found. My interest was specific to the modified arms however the isolation of failure of the original arms to RHD vehicles only also aroused my "professional" curiosity.

So far, I have not heard of any failures of the modified arm and I have not worried about testing the original arms as the mode of failure is readily apparent [reverse cycle cyclic fatigue cracks originating at a forging "crease" on the shoulder of the boss]. The reason for this happening on RHD cars only is still to be determined.

Happy holidays - do you have a "leave pass" to escape the Michigan winter for more comfortable regions? |

William H. Trovinger II

Grand Master

Username: bill_trovinger

Post Number: 180

Registered: 8-2003

| | Posted on Saturday, 04 December, 2004 - 13:11: |    |

John;

I have several points to make on your latest post in this thread:

1) Let us get the record straight you claim in your post (of 02.12.04) I said:

“As I recall, it was YOUR goodself who very much suggested YOUR "right to KNOW" the details of the analysis of "363" fluid, being an analysis, sought by, paid for, and held by me. It was not available to you then, nor is it ever likely to be, despite your moral posturings (at the time) about the "obligations" etc.,of "helping" fellow "R-R" owners etc. You are correct in that I have not volunteered my "qualifications" nor do I feel obliged to do so.”

When in fact what I said was (post 20.08.04):

“On your comment “question any obligation on my part do do so,” I would not say you should look at it as an obligation but more as community service. Many in this forum donate valuable information, yes some has come easy but other information has come at expense to the contributor. Oh, not always a cash expense some more likely is through their personal effort and/or time and I am sure all would agree that time is more valuable then cash, unless one is under 30 that is.”

So unless you are going to get your facts straight I would ask that you refrain from making false claims like that!

2) Additionally, I have a hard time following you. When you make a claim nobody has the right to inquire as to the supporting information, like the case of the RR 363 issue. Yet, it seems you wish others to tell their whole lives story or else no credence should be given to their opinions. Remember the old expression “you can’t have your cake and eat it too” or maybe better would be the one “those who live in glass houses should not cast the first stone”.

3) For the most part I believe that the contributors to this great forum are taking the time to post answers not for self-glorification but rather in a true effort to help others and thereby help keep these wonderful motorcars on the road for all to enjoy. I think that great praise should also be given to the Moderators and Webmaster who keep this site going.

To the other forum readers;

Now I have said my piece and hope that this tread can get back to it’s original intent.

Best regards to all,

Bill

|

whunter

Grand Master

Username: whunter

Post Number: 114

Registered: 10-2003

| | Posted on Saturday, 04 December, 2004 - 14:41: |    |

Thank you David.

Much relieved on that issue.

I like Michigan winter weather, and driving in it, no pass for me and mine.

Today I saw a rusted out 1965 or 1966 RHD Silver Shadow on a roll bed wrecker, going down the highway.

What drew my attention was the broken steering gear hanging under it.

From now on, a camera will be in my pocket, to catch pictures like that.

You would have been impressed with the incredible volume and penetration of rust. |

John D

Unregistered guest

Posted From: 144.138.194.40

| | Posted on Saturday, 04 December, 2004 - 15:12: |    |

Thank you William. Upon refection and review of the posts referred to, I remain of the view that I was, perhaps not by intent, being placed under an obligation (to reveal the "363" formula) in order to serve a perceived "right" for members at large, "to know" . I did not (nor will I) table the analysis for TWO reasons. 1/ Publication COULD violate legislation concerning proprietory property rights etc;either here or the USA 2/ It may well have been flippantly dismissed as "inconclusive" or even "RUBBISH".

Moderator's Plea:

John, without divulging any technical data could you please indicate whether RR363 does contain an additive(s) not found in DOT3/DOT4. This will put our minds at rest without compromising privileged information and/or the source of the information. If you knew that you were never able to provide some indication of the findings; I suggest it would have been better to have said nothing about these tests than to "tease" all of us who have an interest in this subject with the fact that we will never know as we cannot afford the testing required to confirm our beliefs.

I have never expected anyone to tell me their life story, HOWEVER when one reads technically oriented assertions which contradict one's knowledge THEN I do not believe it unreasonable to ask for the contributor to declare the qualifications which enable them to adopt such a position. Similarly, if one is to continually dispute/contradict the opinions of QUALIFIED PROFESSIONALS who regularly contribute to this forum in good faith, then the same expectation should remain i.e that formal credentials be established.

In conclusion, I recall the occasion where I believe it was you, who, being upset about something on this forum, indicated your intention to withdraw, thereby ceasing any further contribution. It was I who expressed understanding, urging you to continue with your contributions since, like most people, I am appreciative of opinion when it is being offered as such.

For the record, I have no automotive qualifications, which renders me UNQUALIFIED (NO "standing" as they say!) to vehemently dispute or contradict technical opinion(s) offered by QUALIFIED professionals; ESPECIALLY when most of them are in agreement upon a particular point or issue. (J.G.Dare)

(Message edited by david_gore on December 05, 2004)

(Message approved by david_gore) |

John D

Unregistered guest

Posted From: 144.138.194.254

| | Posted on Thursday, 09 December, 2004 - 05:09: |    |

In response, I can assure everyone that I acted in good faith in a genuine attempt to HELP members without any intention to "tease" etc. I believe that which I volunteered was preferable to saying nothing (about the report/analysis) insofar that, having due regard to legal constraints (and implications) I proffered a statement from which a reasonably clear inference could be drawn, i.e that having read the report, I remained confident with my decision (and that of many others;local and International) to use any proprietory brand DoT 4 spec.fluid in my S/Shadow, having personally done so now for almost eight years. I am not qualified to determine which constituent (if any) represents an "additive" and consider that I (and others) have provided sufficient guidance in previous posts for owners to reach their own conclusions in respect of any undue wear/noise or service concerns. If, in these circumstances, I remain seen to be,"witholding information", then I do not believe it could be reasonably compared to those who have advanced technical argument without supporting evidence to validate their sbmission.

(Message edited by david_gore on December 09, 2004)

(Message approved by david_gore) |

John D

Unregistered guest

Posted From: 144.138.194.214

| | Posted on Friday, 10 December, 2004 - 06:21: |    |

Further to the foregoing I recently wrote to the U.S SAE, asking if they were aware of ANY need to periodically loosen and retorque ("every couple of years or so") Pitman Arm retaining nuts. A hard copy of the following reply is available and I quote verbatim. "I am responding as Chairperson of the SAE Fasteners Committee. You have raised a specific question about a fastener joint. The SAE Fasteners Committee covers dimensional,mechanical and performance characteristics of the fasteners themselves and dont get involved with the design of actual fastened joints. I would expect any requirements for loosening and re-tightening of fasteners would be covered under maintenence schedules for the particular vehicle sold. This would be similar to changing a timing belt at 60,000 miles for instance. You might want to enquire at the proper vehicle dealership where the particular vehicle is sold and serviced. Also, whoever made the assertion should be able to back it up with proper documentation" Chairperson, SAE Fastener Committee.[Message ENDS] I draw readers attention the FINAL TWO LINES and invite them to ALSO review (see prev. post/s) the comments from a U.S based OEM manufacturer of Pitman Arms (and arm nut retaining "kits") some of which are currently supplied to a well known make of military vehicle. It is perhaps opportune to remind readers (in particular, Series 1,Shadow owners) that this issue has been (and remains) SAFETY RELATED. I intend to politely inform our friendly and authoritive, U.S advisors, that the suggestion which called for this hitherto UNHEARD of "maintenence procedure", did NOT, in the initial instance, emanate from Australia.

(Message approved by david_gore) |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 484

Registered: 4-2003

| | Posted on Friday, 10 December, 2004 - 23:52: |    |

Interesting. And, boy do I hate changing that stupid timing belt and tensioner on my BMW every 60,000 km (not miles) or less. Ridiculous design. At least the factory defines it though. |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 153

Registered: 9-2004

| | Posted on Saturday, 11 December, 2004 - 04:46: |    |

Richard. Try Maserati duplex chains and renold tensioner replacment,as the manual states hours!

Found a far easy way leaving engine in, just like the pitman arm torque safety proceedure not in the manual.

And it is to be shared with folk in due course.

Mercedes have always had chains and some BMW's.

Am i correct that RR never had chains just gears?

Next generation of most makers engines will have chains again i am informed.  |

Richard Treacy

Grand Master

Username: richard_treacy

Post Number: 486

Registered: 4-2003

| | Posted on Saturday, 11 December, 2004 - 05:31: |    |

R-R always had sidevalves and/or overhead valves and they always had timing gears. That was before BMW and VW engines found their way in with overhead cams. Thank goodness for timing gears. For a short while, some had fibre gears which lasted just 80,000 miles, but the valves never foul the pistons when they fail. Better a rattly metal gear (rare) than a worn out fibre gear (always happens).

Chains are the worst by far. Ask any pre-1990 OHC Jag owner, or the owner of any pre-1989 Porsche. There is no scheduled maintenance on camshaft chains, but when they let go it's big trouble. Valves, pistons and casings disintegrate.

At least drive belts are a scheduled maintenance item, and very rarely let go if the belt and tensioner is replaced as defined. The only bad ones I know of are early Alfasuds with no belt cowling. A mate at university had one which lost its belt just one day out of its new car warranty, only one year on a new car back in 1975. Alfa sent him packing, so I replaced the valves for him: two were bent at 30 degrees. Incredibly, it happened at low RPM, waiting at the traffic lights, otherwise the pistons would have been destroyed too. |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 154

Registered: 9-2004

| | Posted on Saturday, 11 December, 2004 - 06:10: |    |

Richard The Ford Essex engine had the fibre gear and they would let go on the boss.

Regarding the cam belts breaking before schedule times.

Have had water pump seizure taking the teeth off the belts with disastrous results on some cars!

Oh well back to the pitman arm sorry,any thoughts on the directional torque within the sub frame and the deletion of the panard rod?

It bugs me that it is just rhd. |

John D

Unregistered guest

Posted From: 144.138.194.102

| | Posted on Saturday, 11 December, 2004 - 05:30: |    |

Thank you Patrick, for yours of 11/12. At line 3 you refer to the "pitman arm safety procedure not in the manual", followed (at line 5) "and it is to be shared with folk in due course". ARE you saying that you will post published technical data to validate this statement?

Repetitious material from past posts removed

(Message edited by david_gore on December 11, 2004)

(Message edited by david_gore on December 11, 2004)

(Message approved by david_gore) |

John D

Unregistered guest

Posted From: 144.138.194.102

| | Posted on Saturday, 11 December, 2004 - 06:19: |    |

Thank you Richard. I have owned 911s for 30 years and have never had a chain (OEM type) actually break (nor have any owners whom I know) however chain tensioners (PRE hyd.feed; mains oil pressure type) have certainly been known to fail, causing the chain to "skip" a tooth (or two) with the drastic consequences which you correctly

describe.I suppose that is why "R-R" seem to have had an aversion to chains/tensioners etc.,the immortal "Merlin" deploying shafts/bevel gears for valve actuation and other accessory items. ooOOPPS!!...no, NOT my 911 chain tensioner, but silly ME (and others) wandering OFF the Thread/topic, which is "PITMAN ARMS". Let us resume our focus thereon, lest unrelated topics provide avenues of diversion from the prime issue/s and specific points currently under active discussion herein.

MODERATOR'S COMMENT:

Gentlemen Whilst we strayed from the original topic onto other topics including references to non-R-R/B vehicles; I used my discretion in allowing these references to be posted as a courtesy to Richard Treacy for his unwavering support of our website. If you wish to discuss non R-R/B vehicles with our contributors, please use the direct contact facilities included in the USER LIST available to registered users.

(Message edited by david_gore on December 11, 2004)

(Message edited by david_gore on December 11, 2004)

(Message approved by david_gore) |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 161

Registered: 9-2004

| | Posted on Saturday, 18 December, 2004 - 10:18: |    |

Has anyone in the Uk a cracked drop arm as i can have a full test carried out to determine where and how the fracture started.

There may be more of a chance of a RHD car with the numbers produced and still with the old type arms in use here to this day. |

Patrick Lockyer.

Grand Master

Username: pat_lockyer

Post Number: 253

Registered: 9-2004