| Author | Message | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 716 Registered: 07-2018 |

I have 28 Lbs. written down in my manual, and I have no idea where I got that from, but I always thought that was a bit low. I think that spec was for the 5/16th studs. Flying Spares list 40 Lbs., but that seems a bit high; maybe not for the 3/8th studs. https://www.flyingspares.com/shop/rolls-royce-bentley-mkvi-r-type-dawn-wraith/engine/cylinder-head-rocker-shafts/cylinder-head.html I read somewhere that one can over do it and crush the head. | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 717 Registered: 07-2018 |

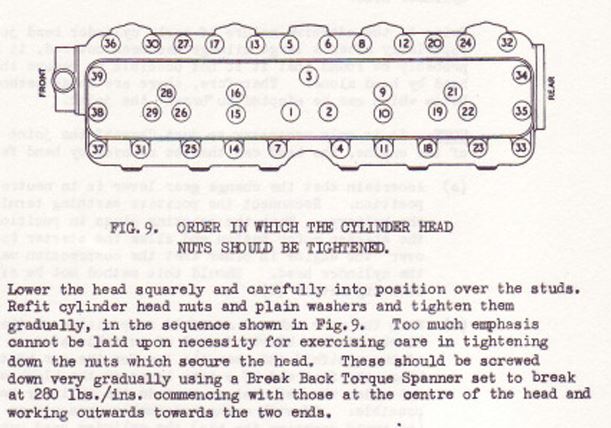

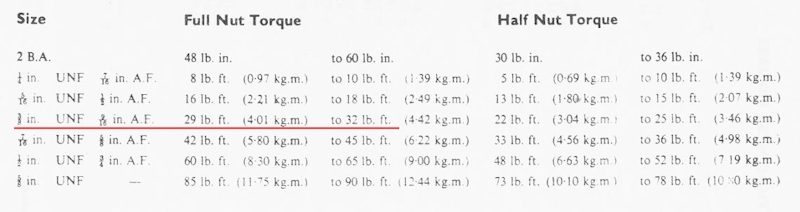

So I checked to see if there was in fact anything in the manuals, and there was, but not very helpful. The R-Type manual says 280 inch/Lbs, that equates to 23.33 Foot/Lbs. (seems really low) I'm going to assume that's the old spec that applies to engines that still have the 5/16th's studs in them. The S1/SC1 Cloud manual says 29 to 32 Foot/Lbs., but that is for 3/8 UNF, I don't see a problem applying that to BSF 3/8th. The 40 Foot/Lbs, came from the RRBSA (Rolls Royce and Bentley Specialist's Association). I did contact them with this, and I'm awaiting an answer where they came up with that figure. What have others here used as a torque setting ?   | ||

ChristopherCarnley Unregistered guest Posted From: 86.153.105.153 |

Jeff, The original MKVI manual for 5/16 studs was the equivalent of 24 lbft for 5/16," studs using a broke back torque wrench. This was abandoned. 30 lbft is appropriate,for 3/8" studs using an needle indicator wrench. Make sure the threads are clean and slightly oily. You cannot crush the head it is RR50 alloy. I am working on an R Type engine not opened since 1952. It is stuck solid on the 39 studs. (Message approved by david_gore) | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 718 Registered: 07-2018 |

You have my sympathies on the R-Type, I will tell you what I did with mine, but I'm sure you already know what's ahead. I got as many studs out as possible, using 2 nuts, I turned one of the nuts down to make it thinner and that went on the bottom, and used the thick one on the top. I was breaking quite sweat working away rocking the stud back and forth. The outside group at the rear of the engine above the exhaust manifold were the culprits, as well as some of the ones right in the centre _ oddly enough. I made all these maple wedges and it started to gradually move about 1/8th of an inch. When I got that far, I tapped the head back down with a plastic mallet filled with lead shot _ repeat... I worked on it a few days at a time over several weeks, and one day it came far enough where I could work it off with my bare hands. I was in my 30's back then, and now at 60, I could still do it, but I don't think I could go at it like I did back then. I also used a Snap-On collet device with a 10 mm metric thread with a pitch of 1.25 fit the BSF threads well enough. I was abusing the tool, reefing on it to get it tight enough. The part number on that is CG-500. |