| Author | Message | ||

Stefan Morley Grand Master Username: myupctoys Post Number: 319 Registered: 7-2009 |

Hi, At it again. Been able to get to 3500 rpm and prove the boost is being regulated, manifold and cast elbow seals, the waste-gate is functioning and that the car isn't knocking. Also that the dump valve seals and functions. Most of it is pretty good. Having difficulty setting the EHA. Not happy with the AFR readings, both at idle and power wise when under boost. Pretty certain the compromise positions I've set the EHA and mixture means one or other end of the range is out of wack. Think I've found the issue but want to ask opinion first. When I had poor fuel flow, pressure was fine now I get good flow I get higher pressure than required and it moves a bit depending on fuel demand. Think the issue is related to the return line back to the tank, there is a significant kink in it near the back wheel. It is either the kink or the pressure regulator just can't deal with the increased flow. BTW This is a great reference to cross relate CO with AFR. http://www.perfectpower.com/index.php?option=com_content&view=article&id=14&Itemid=17 The question. Is there any reason people can see why I cant hacksaw out the kink and replace it with a bit of flexible fuel line. It is a very long return line to have to replace with solid tube. I assume given its the return line there should be relatively low pressure in it. Thanks Stefan | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 775 Registered: 6-2006 |

Hi Stefan, Rubber fuel hose will be fine. Obviously make sure it is not chaffing etc. Most fuel hose will cope with the HP side as well if you can clip it securely enough. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2395 Registered: 4-2003 |

Stefan, Do cut the offending line and replace it with hose. I replaced all mine with expensive Crewe parts in 2000 and it was not at all difficult. The picky Swiss registration station insisted that they be replaced and not duplicated for its quirky safety standard. The old ones were ever-so-lightly corroded from road salt. However, for a short section, a piece of hose would be best. As to the CO, honestly the best is to set a smooth idle. Adjusting the CO should see the revs rise then plateau. Once the plateau is found, I feel another 1/8 turn is almost ideal. Then reset the idle to 580. Again, the Swiss insisted on an idle CO of 1.3 - 1.5. Nuts. When I brought the car back to Australia I reset it as mentioned above and achieve a reading of 0.9 when really well warmed up and run for 10km. Incidentally, with the higher CO setting it was harder to start when very cold due to slight flooding, hence my special cold start timer. Especially at -15C that was noticeable, but with the timer set to 0,5 seconds starting was instant. As I put a pot on the timer, I simply increased the time limit when I dropped the CO, so starting remains on the button. As to the knock sensors, and to answer your question earlier, the knock sensors wind back the boost if the engine knocks. With our 98 octane V-Power the knock sensors are just about working when accelerating hard. 100 RON is better but no longer easily bought in Australia. It always concerns me that the engine is constantly relying on the knock sensors to avoid destruction when you are giving it stick. I really noticed the difference with the lower octane fuel here, and can tell instantly when a rogue service station sells you 95 unleaded from a V-Power pump. When I ran 100RON pump fuel in Europe it was almost at the point where the knock sensors did nothing, but still not quite. Most annoying are full-throttle upshifts unless you do something. With the standard transmission governor settings, upshifts occur around 3700. Once the upshift starts to load the motor to reduce the RPM, the knock sensors kick in and the turbo shuts down for ¼ to even ½ second because the knock sensor control loop gain is set too high in the ECU. Reducing the loop gain would improve that, backing the boost of a little less severely. Short of an attenuator at the knock sensor I personally cannot fix that without the source codes for the ECU. I bought a B&M governor kit and spent a day setting the weights to achieve upshifts at 4300 full throttle and it is better, but that slight shutdown when changing 1-2 at 110km/h is annoying when the fuel is off-spec. In that case I can ride through it by holding Low until 4500. Incidentally, the 2.28:1 final drive like mine (and yours too I assume) is great in Australia as you can enter the motorway and go to the fast lane at the speed limit all easily in first gear. Furthermore, the ratio helps to reduce wheelspin. Mine is pretty good in that regard compared to the Australian-spec 2.69:1, but when the tyres let go all hell breaks loose. If you haven’t floored it from zero to 115 for a while, that can lead to a grey-black cloud from the exhaust as the soot burns off – quite impressive I think. I would far prefer that the knock sensors backed off the spark rather than the turbocharger I must admit. With a B&M adjustable modulator I now have the transmission working as I like it. The original modulators allow part-throttle downshifts to early for my liking, especially with all that engine torque from 1800rpm upwards. RT. | ||

Stefan Morley Grand Master Username: myupctoys Post Number: 320 Registered: 7-2009 |

Thanks so much for the comments. Useful to know how the knock sensor symptoms manifest themselves. Definitely not there based on the comments. 1/4 to 1/2 second cutout would be seen in the recorded logs. The way I went through the tests was shorting out the knock sensor inputs on the boost controller. Boost was still nicely regulated. Then disabled the wate-gate, dump valve regulated at a couple of PSI greater. Reason I'm checking things out is under full boost initially great acceleration, then when I get close to the peak boost, acceleration drops right off. Still accelerating but nowhere near where it should be. Boost pressure remains constant once reaching peak. Pretty certain I'm way too rich under heavy load even though I'm close at idle. Hence measuring the pressure and finding the kink in the return line. I've noticed what your talking about with setting the mixture re starting etc. Will revisit when I get this regulation under control. Will fix the kink tomorrow. Stefan | ||

Stefan Morley Grand Master Username: myupctoys Post Number: 321 Registered: 7-2009 |

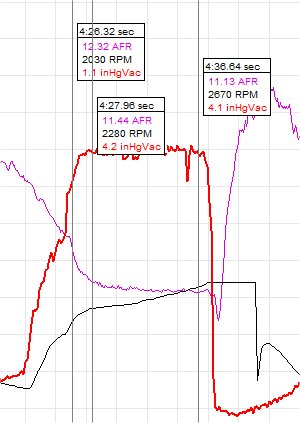

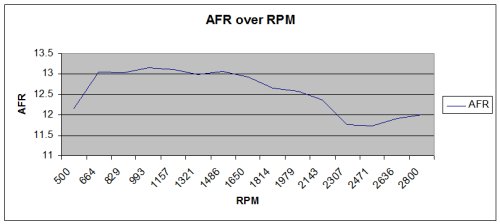

Richard, Picture is worth a thousand words.  Red Manifold pressure, Purple AFR, Black RPM. The LM2 RPM input struggles horribly but this image shows a rough picture of the problem. Apparently a known problem... Bit late now I've bought it. Acceleration is great up to first marker, dropping off to the second and progressive from there. The acceleration change happens when the AFR suddenly drops. Would have expected a more progressive drop of the AFR as RPMs build based on the enrichment from the EHA current.  When the whole AFR data set is averaged over RPM, what is apparent is a kink in the AFR. I've specifically picked only data indicative of acceleration not trailing throttle. The slope and starting point can be changed but this kink exists no matter what the setting. Least that shows whats happening and its repeatable. Fixed the bend in the fuel line but not convinced with readings on my pressure gauge. Have to dig up the other one and verify. Stefan (Message edited by myupctoys on 30 August 2011) | ||

Stefan Morley Grand Master Username: myupctoys Post Number: 322 Registered: 7-2009 |

Richard, Want to make sure my car has the right pressure regulator on it. The RR part number UE70457, is that related to the Bosch Part number is 0438 161 006. Just want to be sure as notice this model regulator is also fitted to 1.9L and 2.3L Mercs of the same era which is a lot smaller engine although still a KE-Jetronic system. Thought I'd better add, 88 Turbo R 22888 although think the regulator should be the same as your car, 87 if I remember rightly. Ordered a new pressure gauge as the better of my two pressure gauges only goes to 85PSI, doesn't quite cut it. Thanks Stefan (Message edited by myupctoys on 01 September 2011) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2400 Registered: 4-2003 |

Stefan, I have checked on my car and can confirm that the correct part is Bosch 0 438 161 006 Sorry about the picture quality though. Let's hope that a new one does the job ! RT.  | ||

Stefan Morley Grand Master Username: myupctoys Post Number: 323 Registered: 7-2009 |

Thanks Richard, Same as mine. I haven't ordered one yet but given the cost thought I should make sure. I'll wait for delivery of the new pressure gauge before buying a new regulator. Hopefully it's just bad fuel regulation. Stefan | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2401 Registered: 4-2003 |

Yes, it's a very pricey piece. List from Bosch is around $600, and I can only guess the Crewe price. They do come up on Ebay if you are prepared to play roulette. The best I have seen is mid $200s. I'll see if I can lend you one for a week from a similar car lying dormant in Canberra when I am back home. | ||

Stefan Morley Grand Master Username: myupctoys Post Number: 324 Registered: 7-2009 |

Richard, Very kind of you. I'll measure the fuel pressure first and see what gives. Thanks Stefan | ||

Stefan Morley Grand Master Username: myupctoys Post Number: 326 Registered: 7-2009 |

Hi, Finally got my new pressure gauge. Just got to figure out what it's telling me. Primary, 87.5 psi, lower 78 psi, difference of 9.5 psi. Both dip about 1 psi when you rev the engine to 1500 ish but seem to track. Will look at the return line to the tank next and make sure that has low pressure. Question, the manual states primary pressure between 82.65>>85.55 psi and lower chambers 75.4>>78.3 psi. What part is critical, the absolute pressure or the difference. Depending on how you look at the numbers, you can get 7.25 psi difference or a range of 4.35>>10.15 psi. Irrespective my regulator is high based on the 7.25 being the important figure. Imagine 7.25 would be the important one as this is the source of the hydraulic pressures acting on the plunger counteracting the air flow past the metering vane. Even discounting gauge tolerances by ignoring absolute pressures I get a difference of 9>>9.5 psi. Going to check a couple of pressure gauges against each other just to see how reliable the readings are. Is the 7.25 psi the critical figure? Stefan (Message edited by m,yupctoys on 09 September 2011) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2416 Registered: 4-2003 |

Stefan, Most important is the difference between those pressures as far as I know. The manual mentions the pressure ranges that you quote in two places. The differential pressure itself is something different. Note that, at the description of the differential pressure valves it states that the valves maintain a fuel pressure difference of 3psi between the two chambers, that differential pressure being the all-important one. I found a manual for the K-Jetronic systems on a Volvo site. The pressure values are presumably different but the principles are much the same. The KE2 has so many similarities that it may be worth a quick read: http://www.volvoclub.org.uk/tech/fuel_injection/k_jetronic.shtml RT. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2419 Registered: 4-2003 |

Stefan, You say that you have catalytic converters, aftermarket to boot of course because Turbo Rs never had them without KE3 Motronic. Does it have a closed-loop CO Lambda control, and if so how is it hooked up ? The reason I ask is that the basic K-Jetronic systems simply modulate and dump primary fuel pressure to control CO. That would not exactly work with a standard Turbo R KE2 system. RT. | ||

Stefan Morley Grand Master Username: myupctoys Post Number: 327 Registered: 7-2009 |

Hi Richard, The Cat was a Japanese tack on but doesn't have the Lambda control. Only the Cat. Monitored the pressure with the car running as it heated up. The pressure rose about 1.5 psi over the course of 15 mins. Ties in with the difficulties I'm having with setting things. Has to be some sort of flow issue back to the tank or the regulator isn't coping with the flow changes. The pressure regulator know nothing about the operational temperature of the car. All it tries to do is regulate and the only thing that changes is the flow of fuel based on the current through the EHA and the amount of fuel the regulator needs to return. Pressure dropping and rising based on demand certainly ties in with all the stupidities I see with the AFR logs. Trying to look for additional kinks in the return line to the tank. Be nice if I find another. Stefan | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 793 Registered: 6-2006 |

Hi Stefan, Which pressure rose and was it from cold to hot or hot to hot etc? |