| Author | Message | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2318 Registered: 4-2003 |

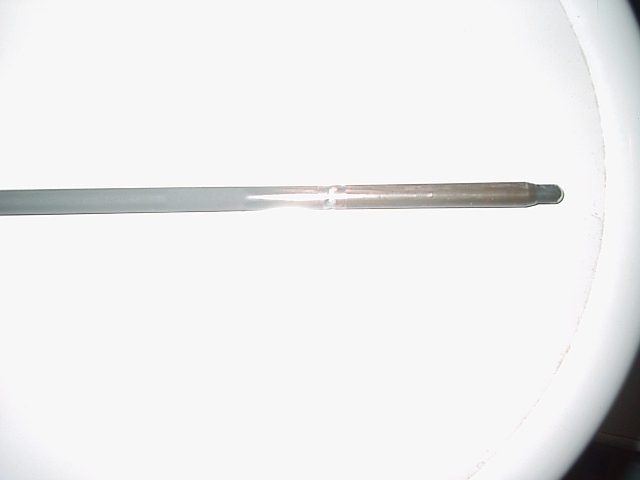

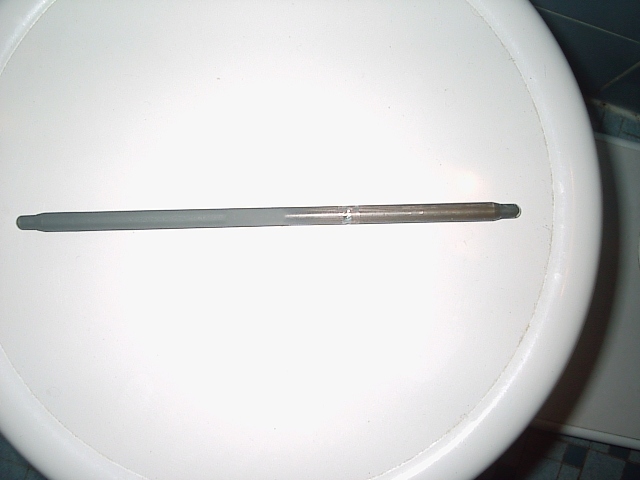

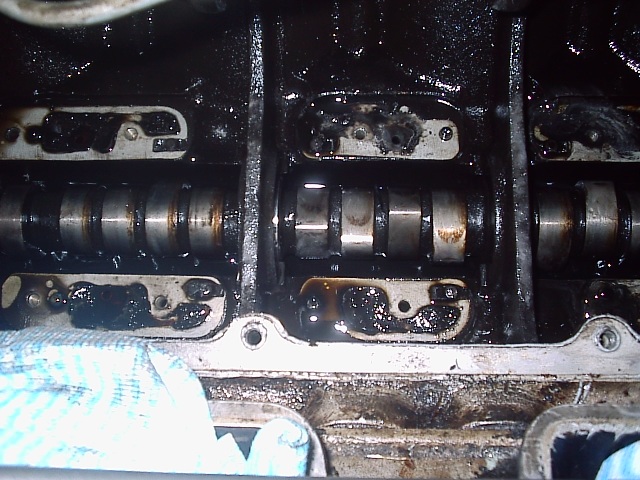

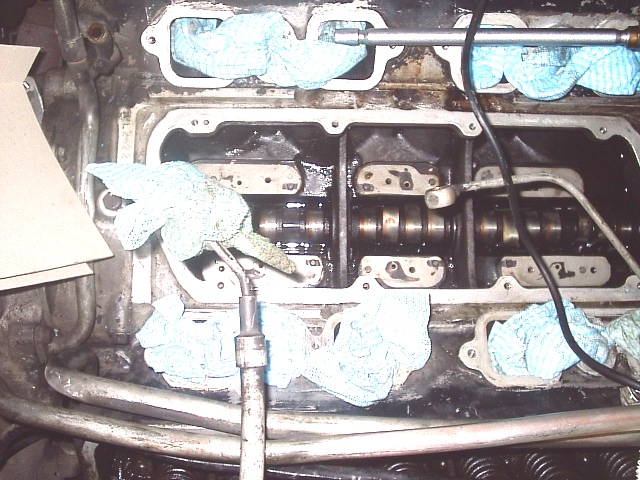

Have you ever seen a pushrod butchered by a previous repairer ?    I can only guess why they were held in vice grips or whatever. Someone deserves a serious organ removal. Then there was this one.  The others looked OK until I cleaned them.  Fortunately, the new ones cost only $20 each, less than the price of an Iridium spark plug, and arrived from the UK in two days. There was a bit of mess to clean up once I had removed the tappet bocks.   | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2320 Registered: 4-2003 |

So, ten pushrods had been mauled exactly the same as that in the first few pictures. One of those has snapped into two pieces, and another is in an S-bend as shown. What Ho !! Thank goodness spares for these cars are so inexpensive. Try buying pushrods for $20 for an FC holden. Let alone sourced by a short phone call to the UK. Forget it. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 735 Registered: 6-2006 |

Richard, from the photos these look like something inside the engine may have done the damage. Seized valves? Hydraulic Locked tappets? Are the marks in the same place on all the rods? If they are, maybe a head gasket on the wrong way scuffing it? Can you get some pics on a darker background? Hate to see the replacements go the same way! Mind you, it certainly hasn't had 6000 miles or 6 month oil changes! Unless they've been filling it with road tar. (complete with gravel! lol) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2321 Registered: 4-2003 |

Yes, Paul, I shall take some more photos. The marks are definitely from severe tooling on some bench, and the head gaskets are clear. The guts are all fairly tarry as you observe, although not quite as black as the pictures show. I can assume that a few valves were seized-ish, but the valves are now all free, and I shall squeeze on some new Viton stem seals as de rigueur. The oil and filter were changed maybe two hour’s running beforehand, and again one hour ago. Cripes-neglect. The oil looks as black as 200,000km despite being almost new. However, the expectation is that the vehicle will be fine soon. I have made up new stove pipe tubing with lagging. By the way, the motor appears to be a secondhand SYL transplant into this 11,000-chassis ex-UK late 1980s import as the chassis and motor serial numbers do not correlate. If you wear dark glasses, the guts of the engine don't scare you so much.   | ||

Lluís Gimeno-Fabra Prolific User Username: lluís Post Number: 134 Registered: 8-2007 |

Richard, What is the cable you are holding? Lluís | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2322 Registered: 4-2003 |

Kickdown. | ||

Omar M. Shams Prolific User Username: omar Post Number: 190 Registered: 4-2009 |

Richard, You have inspired me to look into my Shadow 1's guts. I have tried to tune the car in every possible way from any carburettor settings to any timing settings yet the car either runs rough or has hardly any throttle response. Perhaps it has the same problem as the engine you have shown us? I did wonder if the camshaft was out of sync with the crank, but I better look at the pushrods or valve lifters. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2323 Registered: 4-2003 |

Omar, I dare say that your suspicions are correct. This car had one noisy tappet and a distinct miss every cycle. The noisy tappet was in fact the s-bent pushrod, and the miss was due to the broken and absent one. It had been recommissioned ineffectively after almost a decade. Strangely, even with 1 ˝ broken pushrods, the compression test showed 150psi in all cylinders. Fortunately all the cam lobes are unmarked. I am wondering the merits of trying to flush out all the muck without causing secondary effects. RT. ps I'm still incensed at the blighter who apparently butchered the pushrods. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2325 Registered: 4-2003 |

Gaskets, valve stem seals and pushrods ready to go.  | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 736 Registered: 6-2006 |

Hi Richard, Hopefully the compression being high points more to a seized valve then a tappet pumped up - that would probably have clonked the valve and lost compression. Probably / possible. | ||

Stefan Morley Prolific User Username: myupctoys Post Number: 273 Registered: 7-2009 |

Hi Richard, Can get why a bent pushrod might happen. But what would happen that required someone to choose the path of being heavy handed re-installing a pushrod quite like that. Don't get it. Not to name and shame but just to know what led someone consider the approach in the first place. Stefan | ||

Stefan Morley Prolific User Username: myupctoys Post Number: 274 Registered: 7-2009 |

Just occurred to me. Maybe they where trying to straighten bend rods! Oh dear. Tragic. | ||

Omar M. Shams Prolific User Username: omar Post Number: 191 Registered: 4-2009 |

Dear Richard, will you be checking to see if the cam shaft is in correct synchronisation with the crankshaft at this stage? Between us, we all doubt the integrity of the chap who last went into this part of your engine. why stop at the push rods? As I say, i will be investigating this part of my car when the time is right because I suspect the same problem as you have highlighted but am also concerned that the two shafts may not be accurately set up. Where did you get the seals from? Are they aftermarket ones or genuine Rolls-Royce? | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2326 Registered: 4-2003 |

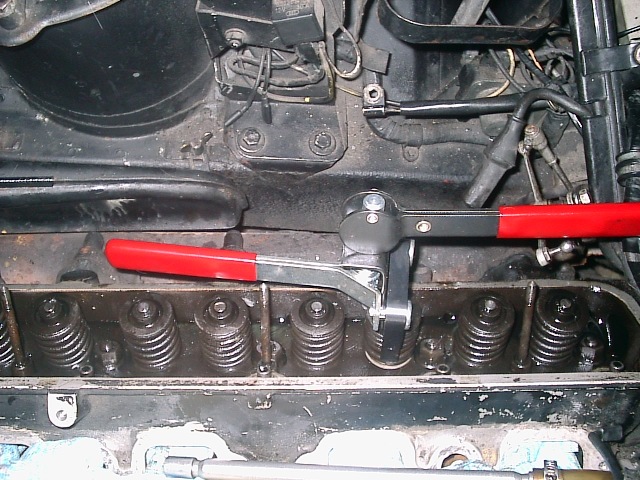

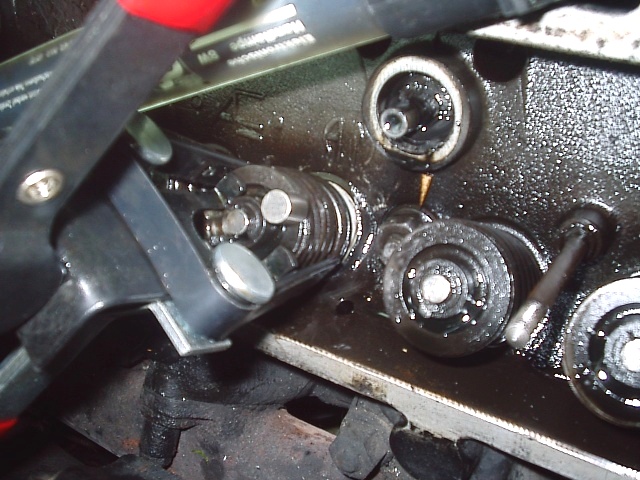

Now it's a bit cleaner.  I'll start a thread on upgrading the valve stem seals. First you must remove the valve springs in-situ.  Throw away the gland spring and the cup which holds the old rope seal grommet. Clean the stem with penetrating oil and check that the valve can cover its full stroke without binding. Blow it dry with compressed air, then apply a dollop of engine oil to the top og the guide. Press on the new seal.   Now refit the spring. Load the collets and cap with RTV before releasing the spring compressor and clean it up when the spring compressor has been released. Note the supermagnet on the side of the valve cap. In case a collet slips out during the procedure, the magnet will catch it.  Now this engine will use no oil at all. RT. | ||

Stefan Morley Prolific User Username: myupctoys Post Number: 275 Registered: 7-2009 |

Richard, Good stuff. Love it when people get stuck into it. 20 years time this info will be a treasure trove. Especially the little titbit's that make the difference. One of the greatest redeeming features of our cars is that if you have a good crack at a job, it stays fixed. And bits of plastic don't break just by looking at them. Cheers Stefan | ||

Stefan Morley Prolific User Username: myupctoys Post Number: 276 Registered: 7-2009 |

Richard Whoops this is the T series era, I don't have one of those. Richard mentioned how much smoother the firing order was in this era. Still the concept holds, fix it right it stays fixed. Dad is still on the hunt. If anyone knows of a understated T series happy to pass it on. Cheers Stefan | ||

Stefan Morley Prolific User Username: myupctoys Post Number: 277 Registered: 7-2009 |

Richard, After taking the collet and spring off how to you prevent the valve dropping down? Presume you have the piston at TDC but if you do that for each cylinder take a bit of finding TDC for 1 again. Suppose it doesn't matter if the cam is still relative. Stefan | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2327 Registered: 4-2003 |

Stefan, quite correct. At TDC the valve can only drop about 5mm, and that is enough for safety. Fiddling to refit the collets is a chore. For the last eight valves (maybe tomorrow night) I shall use a compressed air adfaptor to save that last 5mm and make the job easier. The camshaft position has no bearing as the rockets and pushrods are all removed. I cannot stress too much the need for magnets as surety. Use a magnetic wand to lift out and put in the collets. It is great piece of mind to know that a stray collet will not disappear out the garage door. Also, this Stanley valve compressor makes life easy. RT. ps I wish that it were all so clean and tidy as our T-Series.    | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2328 Registered: 4-2003 |

However, some tools are so simple. This long-reach 14mm 3/8" drive socket is all that is needed to press the new valve stem seal home.  Again, removing the collets. Note the magnets. Use the magnetic wand to lift out the collets, but the magnets on tha valve spring cap will catch a collet is it goes astray. It shouldn't, but...,   | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2329 Registered: 4-2003 |

Sorry about the typos. Rockers not rockets etc. The compressed air is pumped into where the spark plug goes to keep the valves fully closed while doing all this. All you need is a 14mm threaded adaptor for the compressed air line. 300kPa will do fine. If the air line bursts then the valve will only fall 5mm and stop safely on the crown of the piston at TDC. RT. | ||

Neville Davies Experienced User Username: nev_davies Post Number: 25 Registered: 9-2006 |

Richard May I add screwing the spark plugs in a couple of turns is not a bad idea if you do not use an airline,just in case the magnet fails Nev | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2330 Registered: 4-2003 |

Points well taken Neville. By the way, can you comment on oil consumption and cleanliness since you fitted the seal upgrade on your Silver Shadow ? With the air hose in place it is easier to crack the collets free from the stems. With the magnets surrounding the stem tip, the collets are also safer and easier to collect with compressed air applied. For me anyhow, the air is not really an advantage when refitting the springs. But then I am only using a portable compressor with a modest capacity as mine is too large to lug around often. Note the excess grey RTV on the spring cap awaiting cleanup after it sets partially. RT.  | ||

Neville Davies Experienced User Username: nev_davies Post Number: 26 Registered: 9-2006 |

Richard. Yes The seals you obtained were the complete answer to the problem. The car in question was in fact a Bentley version of the SZ and I used a spring compressor very similar to the one you were using a little awkward for a couple of the valves but otherwise straightforward.I mentioned the spark plug because when I did my Rolls SZ some years previous I relaxed a little and dropped a collet fortunately saved by putting the plug back in I may have mentioned it when we spoke on the phone.The Bentley however a success no noticeable oil consumption whatsoever.Well worth the effort and fully recommended. Nev | ||

Neville Davies Experienced User Username: nev_davies Post Number: 27 Registered: 9-2006 |

Continuing from my last post I tried using an air-line to hold the valves up but found I needed to lock the crankshaft to stop the piston going down and decided it wasn't worth the effort.It would be interesting to know the cause of the damage to the rods never seen that before. Nev | ||

Mark Aldridge Experienced User Username: mark_aldridge Post Number: 32 Registered: 10-2008 |

Richard,do you have a part number for the valve spring compressor so that I can find a supplier in the UK. Thanks Mark | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2331 Registered: 4-2003 |

Mark, http://www.fixitgy.com/item_page.aspx?itmid=381 The overhead valve spring compressor that you see in this thread is a Stanley 78-053. It cost around A$160 (US$175), and for locals it came from Motor Replacement Parts at 26 Molonglo Mall, Fyshwick, Canberra ACT 2609, Australia. The Stanley 78-052 is similar but slower to use – see both versions through the link above. Mine came with a bolt to replace the handle for tight locations, so I believe that it is more useful than the 78-052 in every application. In the UK, go to www.stanleytools.co.uk/ , however they don’t list automotive tools on the UK site. I tried a search for the Stanley tool in the UK without any luck. However, there are many other brands and they are often cheaper. For example, the Sealey brand can be seen at: http://www.toolshopdirect.co.uk/search.php?what=&search=Valve+Spring RT. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 838 Registered: 9-2004 |

Just had a read up, things imo are pointing to an engine that has run hot causing as Paul has said heat seizure of the valves [with carbon build up within the guides] however it is possible for the rockers to loose oil through many problems when an engine overheats causing some to heat seize. This may also cause the push rods to bow hitting the surrounding area causing the marks on them. It has been know for the head to distort causing stiff operation of some rockers when the motor is cooked. One only has to look at the rust on the inside of the water pipes to confirm probs of other sorts. Always before the start of this kind of job it pays off to do exploratry tests before dismantling and putting the blame on a preivoius repairer. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2333 Registered: 4-2003 |

Overheating ? Heat seizure ? Carbon ? Nah. No need to look for Doomsday when Springtime is in your face. Blame previous workmanship ? Not for the bent pushrods, but certainly for the ones mangled by tools. Classic case of stiff valve stems in corroded guides after a very long sleep will do. It was sitting around for maybe 5 years without being turned over until about 7 years ago. Then it was run once, then again two years ago. A few valves were stuck but are now successfully freed up as evidenced when fitting new valve stem seals. It is fair to expect that the cast iron inlet valve guides can corrode more quickly than the phosphor bronze exhausts once they all go completely dry over the years. The stuck valves will have bent the rods. The rods damaged unquestionably by tools are something else. Without those bent rods we would never have seen the damaged rods, but replacing them all regardless made sense. Recommissioning an engine after so long can be a risky business, and unfortunately it appears that at least the rocker covers need to come off to check for stuck valves after more than maybe 24 months. Otherwise, just clonking the starter motor can bend the pushrods if valves are stiff. Pity the B-Bank rocker cover has all that hardware all over it, and it helps to remove the carburettors, so it’s a little more than a Sunday afternoon job to check the valves for freeness. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 839 Registered: 9-2004 |

Ok how do explain the rust staining in the coolant pipes? | ||

Mark Aldridge Experienced User Username: mark_aldridge Post Number: 33 Registered: 10-2008 |

Richard,Thanks for the direction re Valve spring compressors. Now in hand. Mark | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2335 Registered: 4-2003 |

Now it purrs like a kitten. No leaks. No clicks. Next is to run it for a bit with a few changes of water, then to fill it with proper coolant on Friday. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 840 Registered: 9-2004 |

Great news,are you reverse flushing the rad and changing the thermostat. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2336 Registered: 4-2003 |

Thanks Pat. The radiator is new, as of course is the thermostat. |